Potato drought-resisting, ridging, film-laminating and furrow-planting all-in-one machine

A furrow planting and potato technology is applied in the field of an integrated machine for potato drought resistance, ridge, mulching, mulching and furrow planting. efficiency, labor saving, pool reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

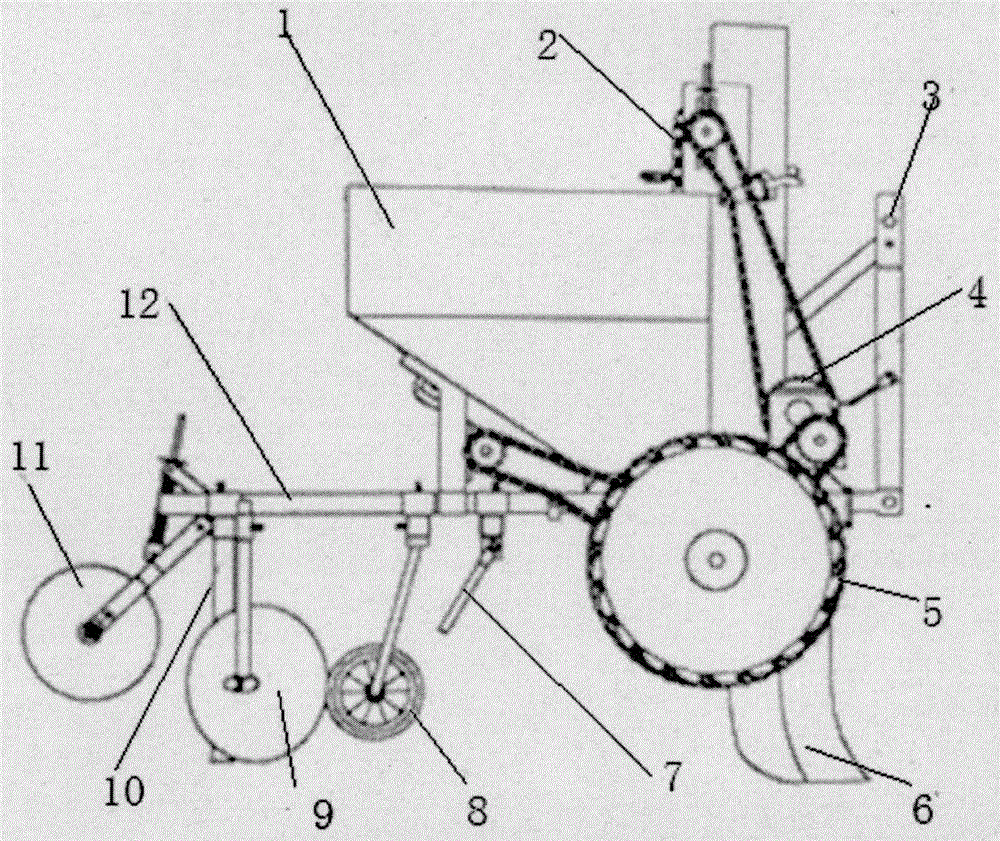

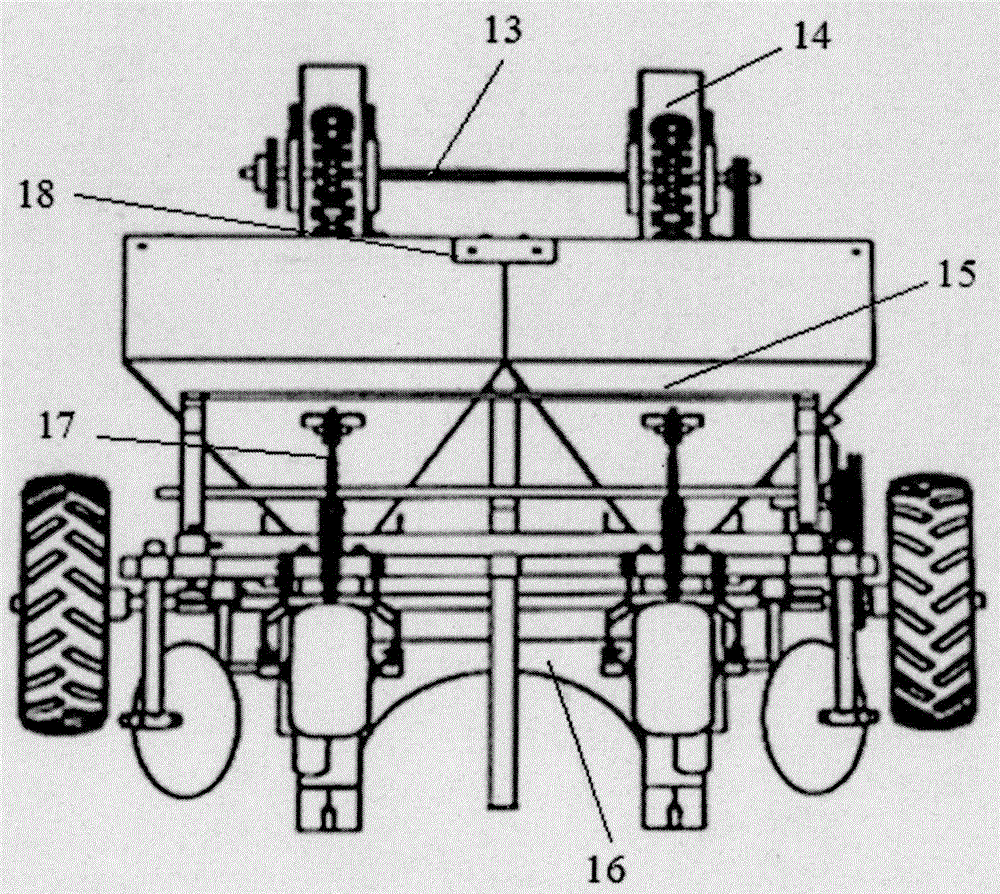

[0015] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0016] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The ridge of this machine adopts the unique design of one-way soil-digging furrow plow, through the operation of furrow plow, the purpose of raising ridges is achieved; the potato seeding trough is directly connected with the furrow plow, and the planting Potatoes are sown in furrows, and the sowing depth can be controlled by adjusting the up and down of the furrow plow; in mechanical use, the mulching rod will slightly smooth the ridge top during the working process after the film is installed, which not only retains the effect of high ridges, but also effectively It solves the problem of damage to the film caused by the unev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com