A high-strength, flexible, light-transmitting and implantable silk protein/bacterial cellulose/graphene composite conductive film

A composite technology of bacterial cellulose and graphene, which can be used in surgery, medical science, etc., can solve the problems of increasing the difficulty of mixing and crosslinking bacterial cellulose and silk protein, affecting the overall performance of composite materials, and high production costs, so as to achieve improvement Evenly disperse the problem, achieve the effect of good uniformity and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

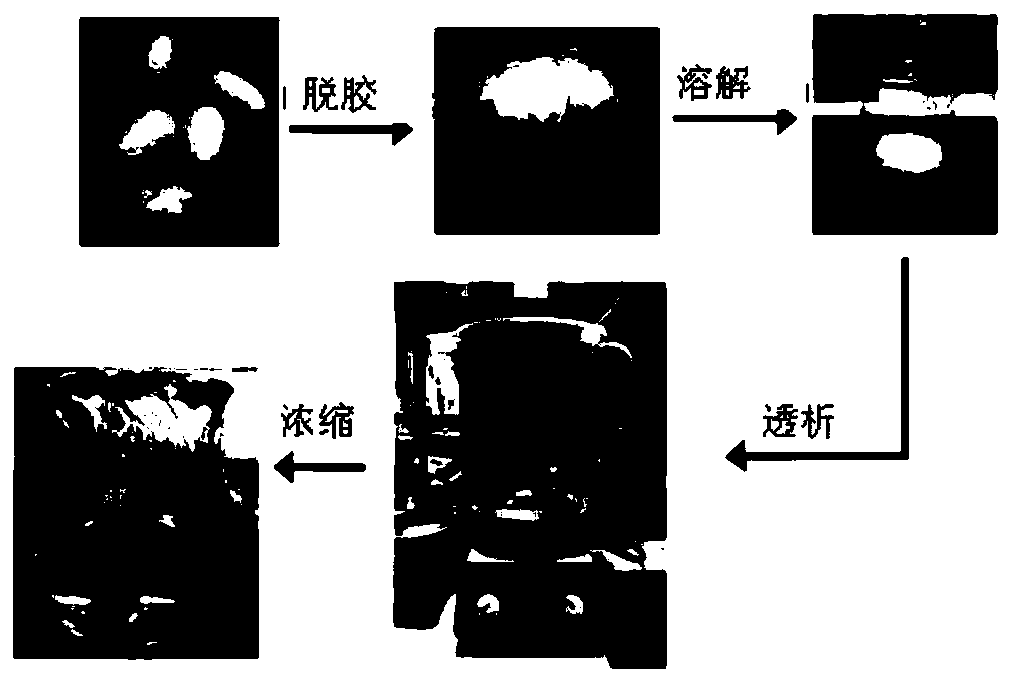

[0038](1) Add coconut fruit bacterial cellulose to deionized water, transfer to a juice extractor, smash to form a diameter of 60-100nm, and a micronano-level bacterial cellulose solution with a length of 0.8-8um, and silkworm cocoons are treated with 0.5wt% Sodium bicarbonate solution was degummed for 45 minutes, washed with water and dried, dissolved in calcium chloride ternary solution for 2 hours at 60°C, dialyzed with deionized water for 3 days to make 7wt% silk protein aqueous solution, and micro-nano bacterial cellulose solution Mix evenly with silk protein solution to form silk protein / bacterial cellulose composite solution.

[0039] (2) Add graphene aqueous solution dropwise to the fibroin / bacterial cellulose composite solution, and stir while adding dropwise to obtain the fibroin / bacterial cellulose / graphene composite solution. Under the vacuum condition of 0.01MPa, the The solvent was removed by filtration through a polycarbonate membrane to obtain a concentrated co...

Embodiment 2

[0042] (1) Add coconut fruit bacterial cellulose to deionized water, transfer to a juice extractor, smash to form a diameter of 60-100nm, and a micronano-level bacterial cellulose solution with a length of 0.8-8um, and silkworm cocoons are treated with 0.5wt% Sodium bicarbonate solution was degummed for 45 minutes, washed with water and dried, dissolved in calcium chloride ternary solution at 70°C for 3 hours, dialyzed with deionized water for 3 days to make 10wt% silk protein aqueous solution, and micro-nano bacterial cellulose solution Mix evenly with silk protein solution to form silk protein / bacterial cellulose composite solution.

[0043] (2) Add graphene aqueous solution dropwise to the fibroin / bacterial cellulose composite solution, and stir while adding dropwise to obtain the fibroin / bacterial cellulose / graphene composite solution. Under a vacuum condition of 0.1MPa, the The solvent was removed by filtration through a polycarbonate membrane to obtain a concentrated com...

Embodiment 3

[0046] (1) Add coconut fruit bacterial cellulose to deionized water, transfer to a juice extractor, smash to form a diameter of 60-100nm, and a micronano-level bacterial cellulose solution with a length of 0.8-8um, and silkworm cocoons are treated with 0.5wt% Sodium bicarbonate solution was degummed for 45 minutes, washed with water and dried, dissolved in calcium chloride ternary solution for 2.5 hours at 65°C, dialyzed with deionized water for 3 days to make 8wt% silk protein aqueous solution, and micro-nano-scale bacterial cellulose The solution is uniformly mixed with the fibroin solution to form a fibroin / bacterial cellulose composite solution.

[0047] (2) Add graphene aqueous solution dropwise to the fibroin / bacterial cellulose composite solution, and stir while adding dropwise to obtain the fibroin / bacterial cellulose / graphene composite solution. Under vacuum conditions of 0.05MPa, the The solvent was removed by filtration through a polycarbonate membrane to obtain a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com