Fun catcher

A doll machine and geared motor technology, applied in the field of doll machines, can solve the problems of low success rate, high success rate, easy to get stuck, etc., and achieve the effects of simple structure, low cost and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

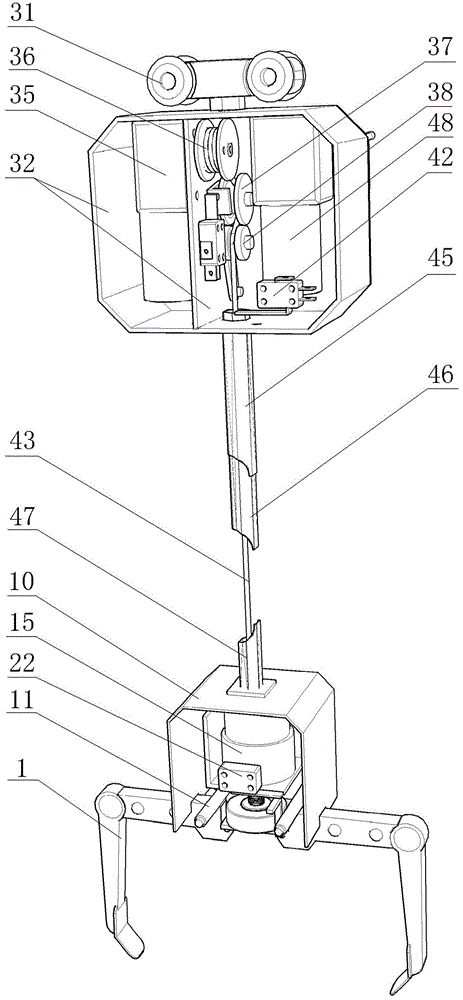

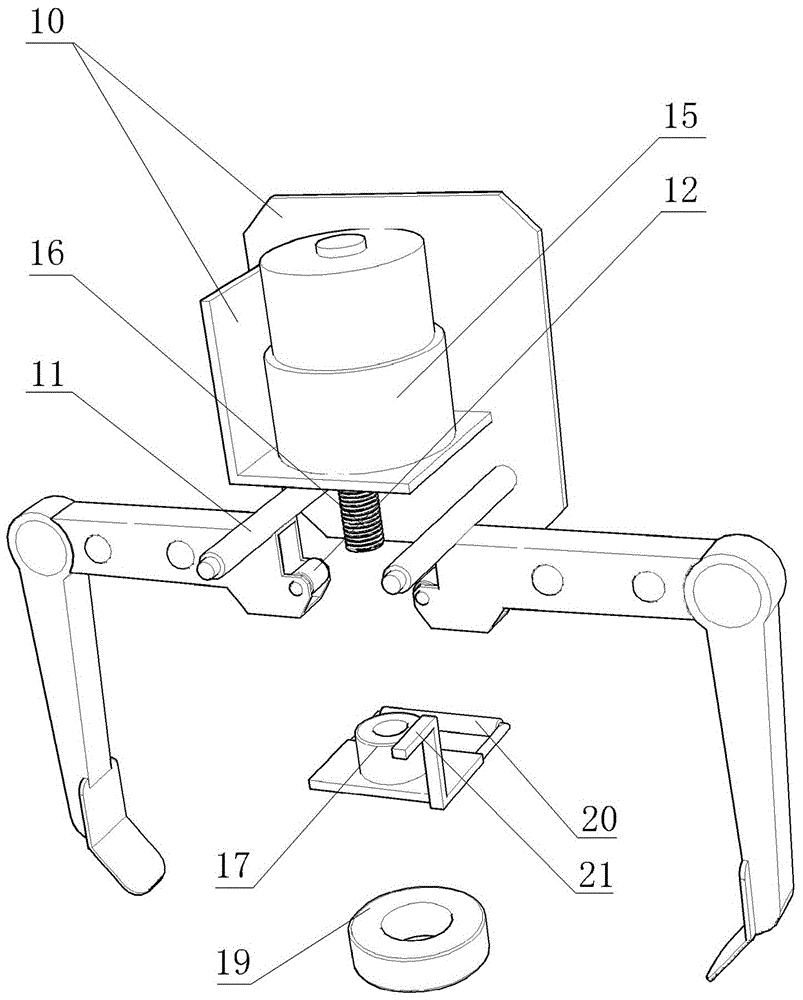

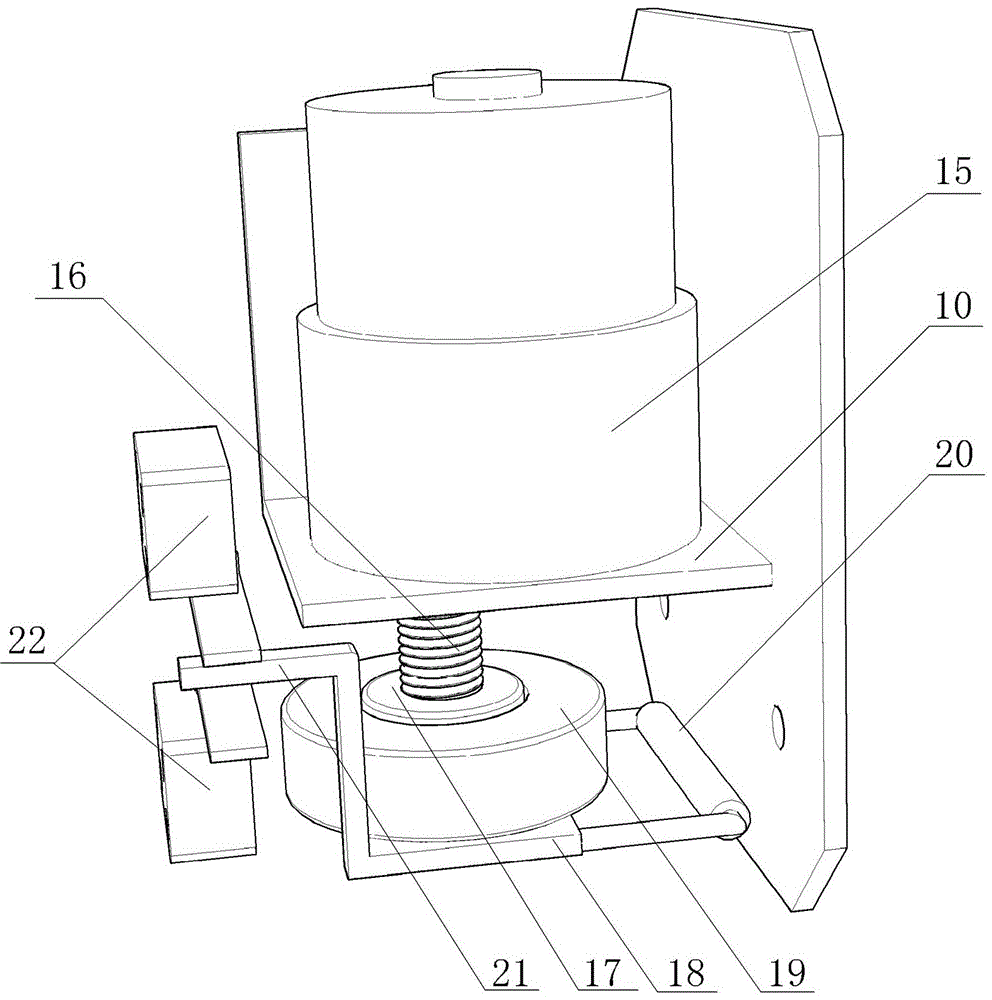

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] As shown in the figure: 1. Clamping, 3. Horizontal bridge track, 6. Longitudinal bridge;

[0029] 10. Clamping frame, 11. Rotating shaft, 12. Pressed roller, 15. Opening and closing geared motor, 16. Bolt sleeve, 17. Nut, 18. Press block, 19. Magnetic coil;

[0030] 20. Limit slide shaft, 21. Travel switch limit rod, 22. Open and close travel switch, 23. Multi-core spiral sleeve; 25. Cable drag chain, 26. Power control line, 27. Drag chain mobile frame ;

[0031] 31. hanging pulley, 32. laterally moving shell frame, 34. switch contact wheel frame, 35. lifting reduction motor, 36. traction wheel, 37. sheave, 38. guide sheave, 39. spring;

[0032] 41. Down travel switch, 42. Up travel switch, 43. Lifting cable, 45. Telescopic rod A, 46. Telescopic rod B, 47. Telescopic rod C, 48. Transverse gear motor, 51 traction Wheel, 52. traction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com