Rapeseed impurity removal equipment

A rapeseed and equipment technology, which is applied in the field of rapeseed impurity removal equipment, can solve the problems of rapeseed waste and inconvenient transportation, and achieve the effects of reducing waste, reducing labor intensity, and improving the quality of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings.

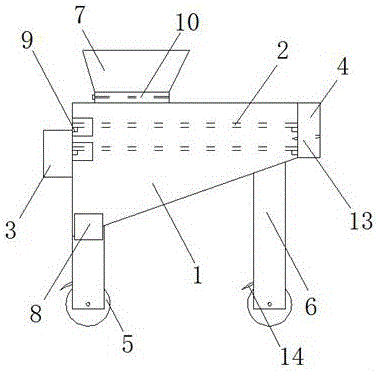

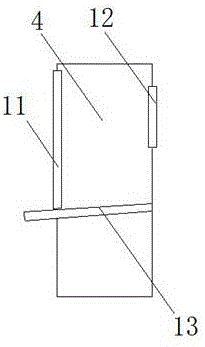

[0014] as attached figure 1 , 2 As shown, a kind of impurity removal equipment for rapeseed includes an impurity removal chamber 1, a vibrating screen 2, a blower 3, an impurity removal pipe 4 and a walking wheel 5, and it is characterized in that: the impurity removal chamber 1 is arranged on the bracket 6, a feed bin 7 and a discharge pipe 8 are arranged on the outer wall of the impurity removal chamber 1, and a vibrating motor 9 is arranged on the inner wall of the impurity removal chamber 1, and an adjustment plate 10 is arranged in the feed bin 7, The rate of rapeseed feeding can be adjusted by the regulating plate 10, and then the impurity removal efficiency of rapeseed can be improved. The vibrating screen 2 is arranged on the vibrating motor 9, and the vibrating screen 2 is arranged as two layers, and the The number of meshes of the vibrating screen 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap