Damping disk progressive die of automobile clutch

A technology of progressive die and shock-absorbing disc, applied in the direction of feeding device, vehicle parts, forming tools, etc., to achieve the effect of improving utilization rate, reducing mold usage, improving production and processing speed and parts production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation process of the present invention will be further described in detail below in conjunction with the accompanying drawings.

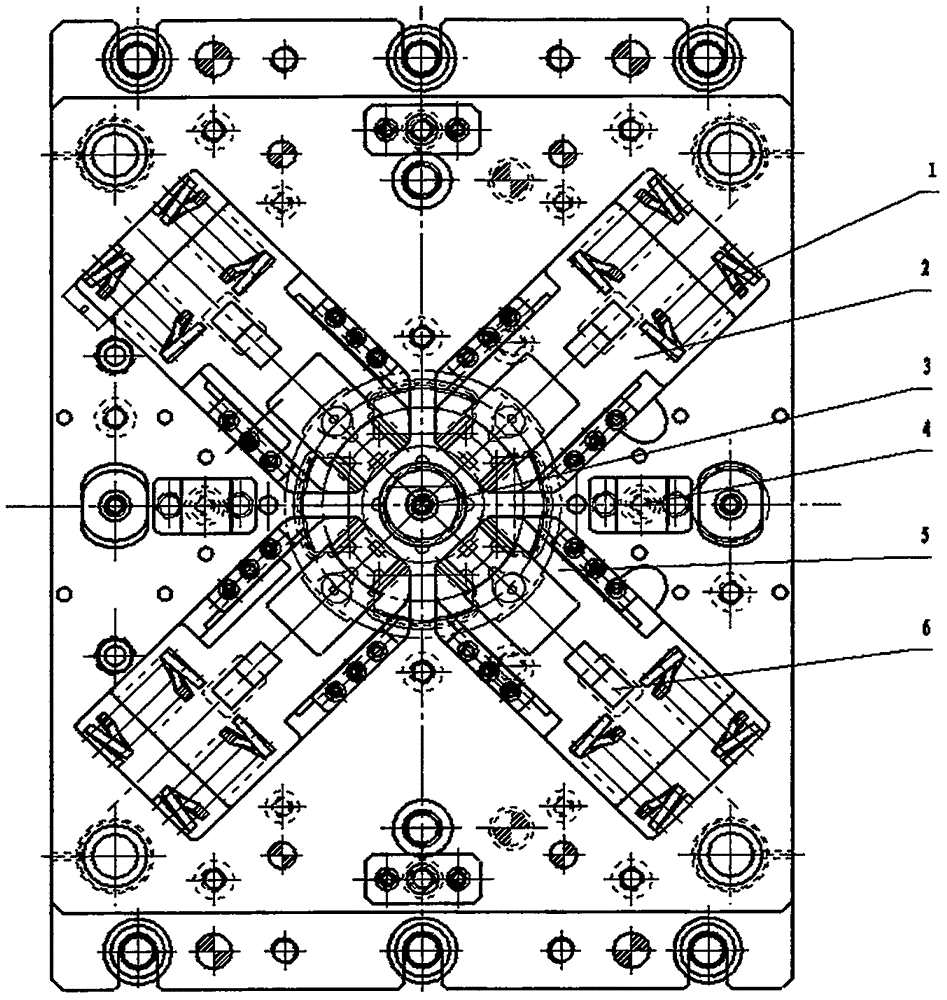

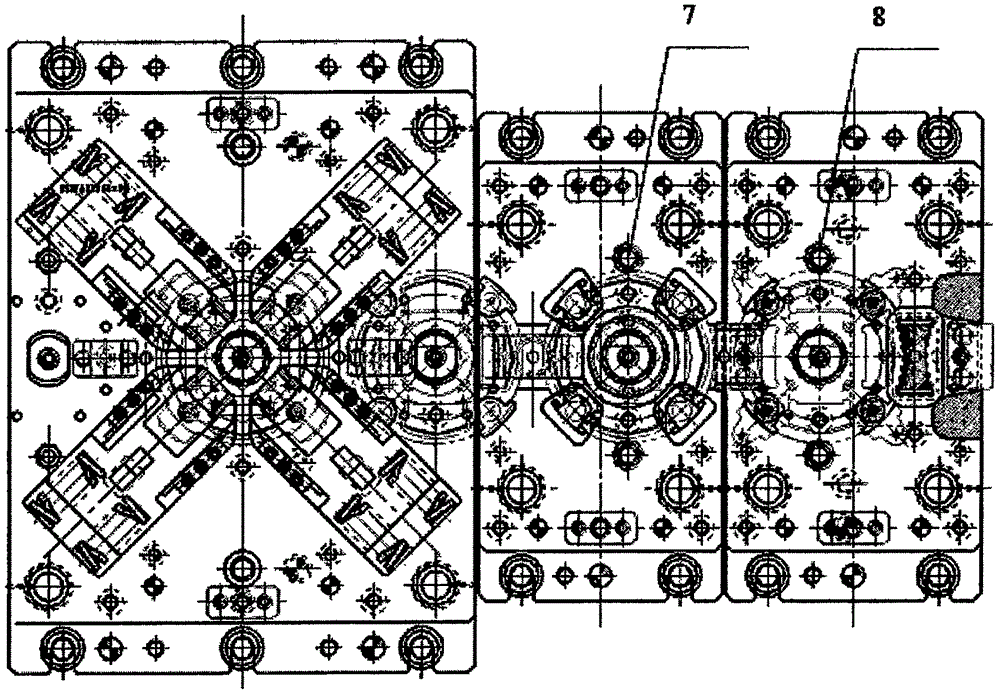

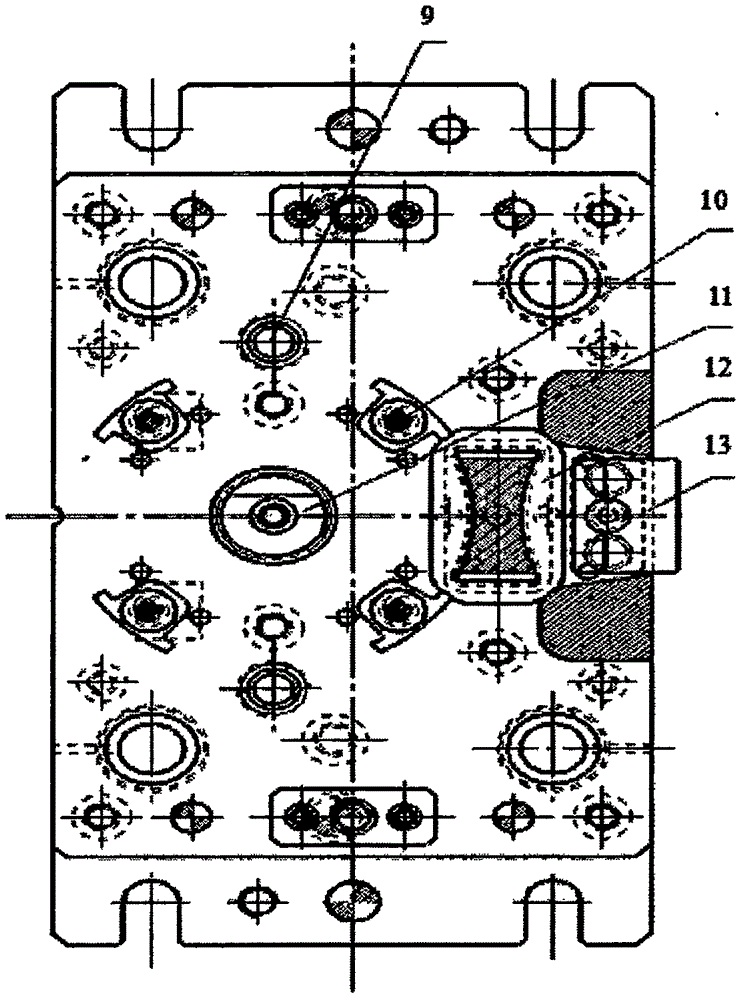

[0031] Such as Figure 1 to Figure 3 Shown: a progressive die for an automobile clutch damping disc, including a progressive die body, characterized in that: it also includes a positioning guide 3 positioned at the progressive die body, arranged in an X shape with the positioning guide 3 4 rectangular oblique sliders 2 deployed as the center, the oblique slider return spring 1 at the end of each oblique slider 2, the bending die 5 at the root of each oblique slider 2, the The inclined iron 6 between the oblique slider return spring 1 in the middle section of each oblique slider 2 and the bending die 5, and the two floating blocks 4 located on both sides of the positioning guide head 3, the The inclined slider return spring 1 can utilize its spring force to reset the inclined slider 2 and the bending die 5, and the recovery time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com