Cooling roller for turbulence high heat exchange amorphous strip production

A technology for amorphous strips and cooling rolls, which is applied in the field of amorphous strip production, can solve the problems of large differences in axial temperature distribution and the degree of amorphousness in the middle of the strip, so as to promote heat transfer in the center of the roller sleeve and reduce Effect of temperature gradient, improving heat exchange efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

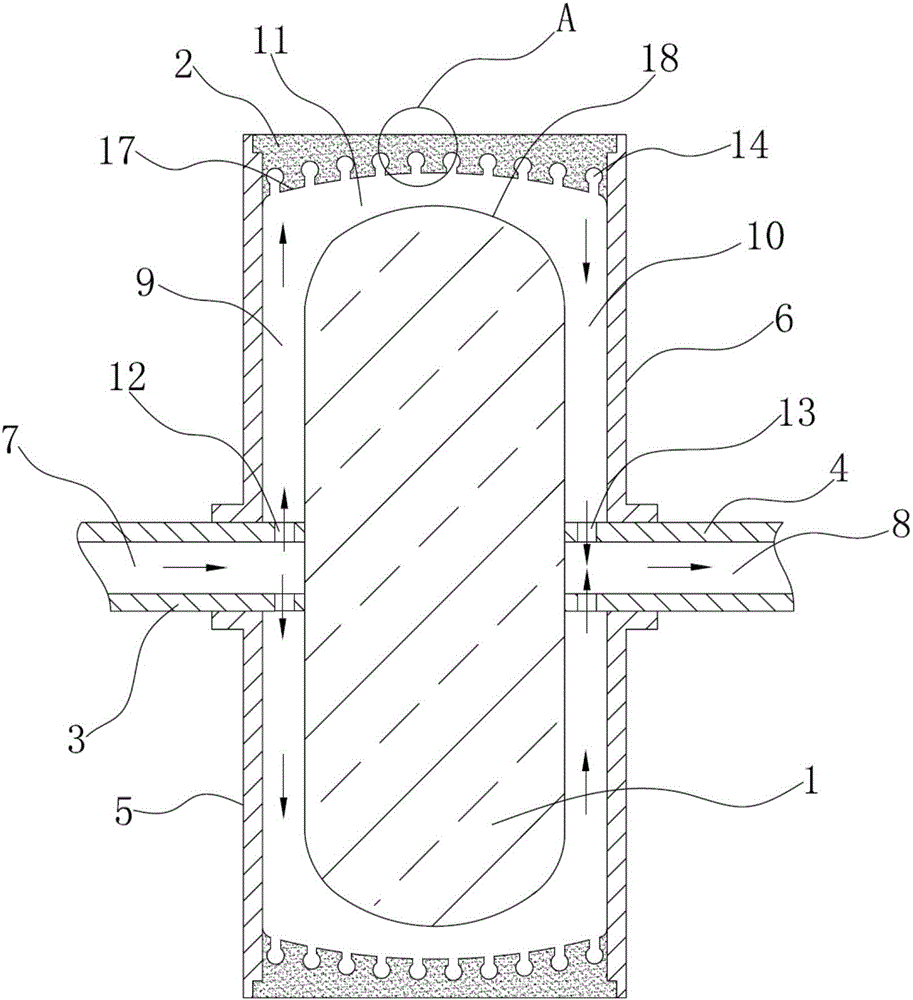

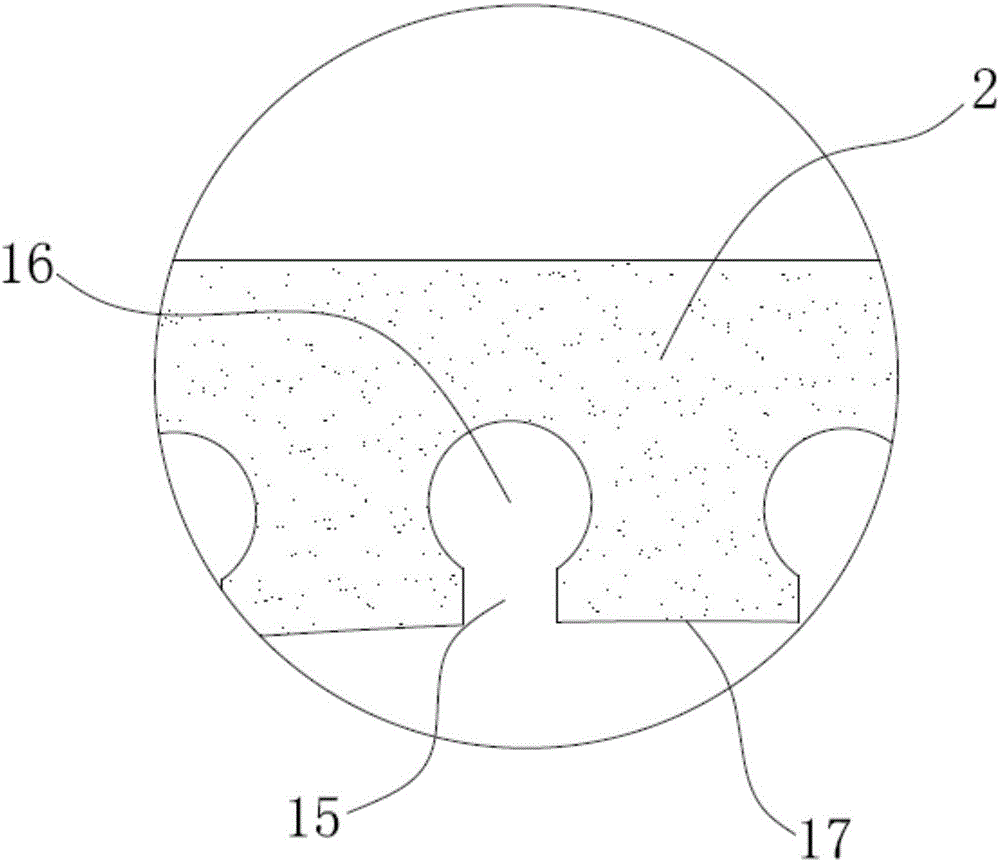

[0022] Such as figure 1 , figure 2 A cooling roll for the production of turbulent-flow strong heat-exchanging amorphous strip is shown, including a roll core 1, a roll sleeve 2, a left main shaft 3, a right main shaft 4, a left cover 5 and a right cover 6, a left cover, The right cover plates are respectively arranged on both sides of the roller core and are fixedly connected by the roller sleeves sleeved on the circumferential outer side of the roll core. The left main shaft passes through the left cover plate and is fixedly connected with it. The main shaft passes through the right cover plate and is rotatably connected with the right cover plate. The right main shaft is provided with a cooling medium outflow channel 8, and the spaces between the left cover plate, the right cover plate and the roller core respectively form the cooling mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com