Subcaliber-polishing contour route planning method

A technology of path planning and contour lines, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of unfavorable surface shape error convergence, increase the amount of excess material removal in the lowest area of the component, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

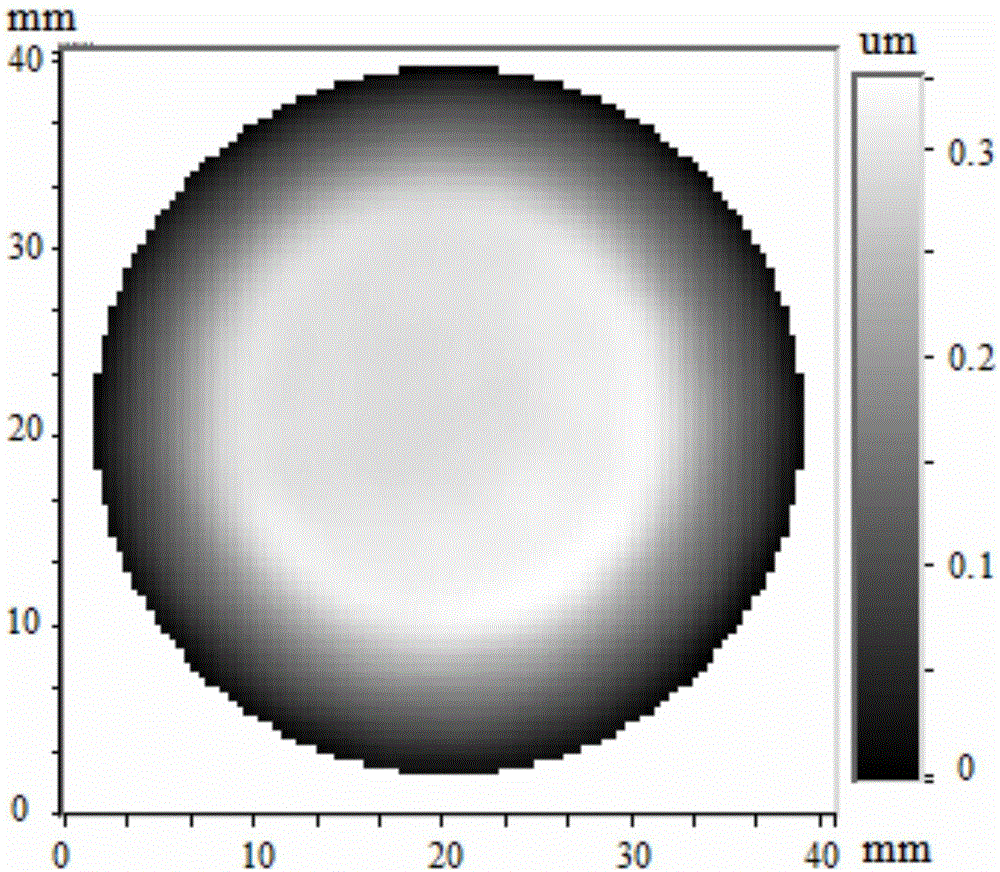

[0038] The sub-aperture polishing of the present embodiment is carried out on a CNC polishing machine tool. The machine tool has three linear motion axes of X, Y, and Z, and a polishing head comprising a revolution and rotation motor. The polishing tool is an asphalt disc with a diameter of 50 mm. The polishing tool is connected to the polishing head through a ball twist. The process parameters are set as follows: the revolution speed is 100rpm, the rotation speed is 20rpm, the polishing pressure is 5kg, and the removal function of the asphalt disc is as follows: figure 1 shown. The component to be polished is fused silica glass of 400mm×400mm.

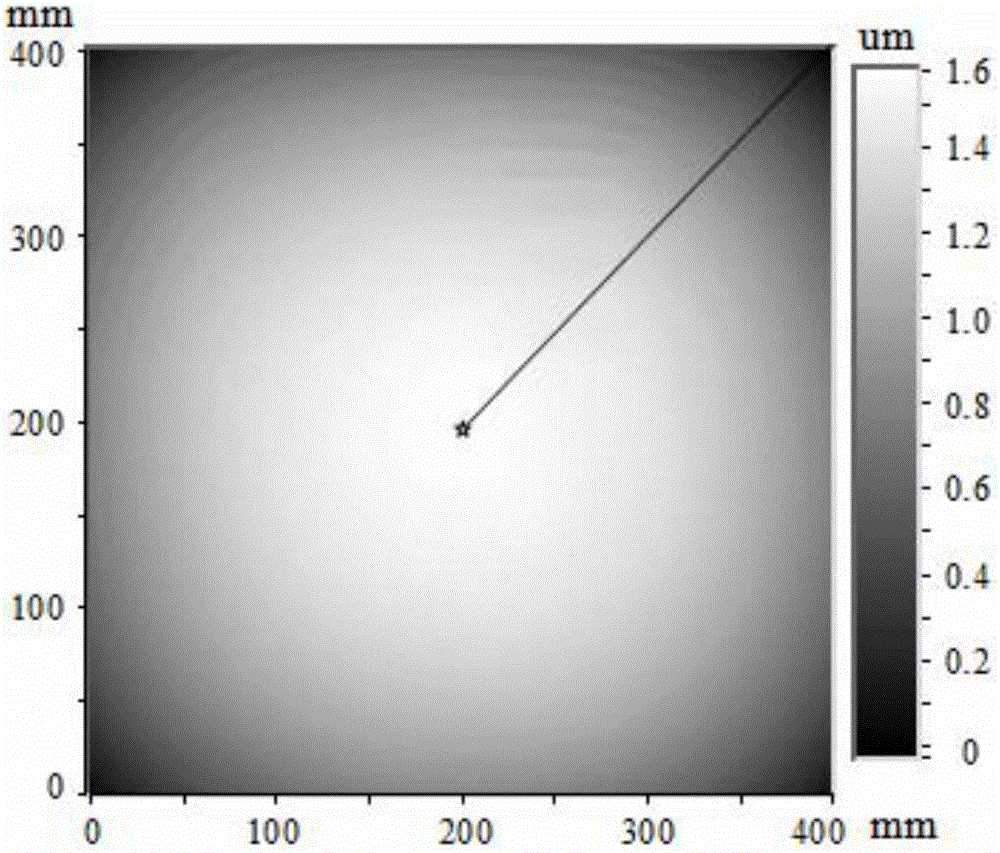

[0039] The steps of carrying out numerical control polishing to the above-mentioned fused silica glass are:

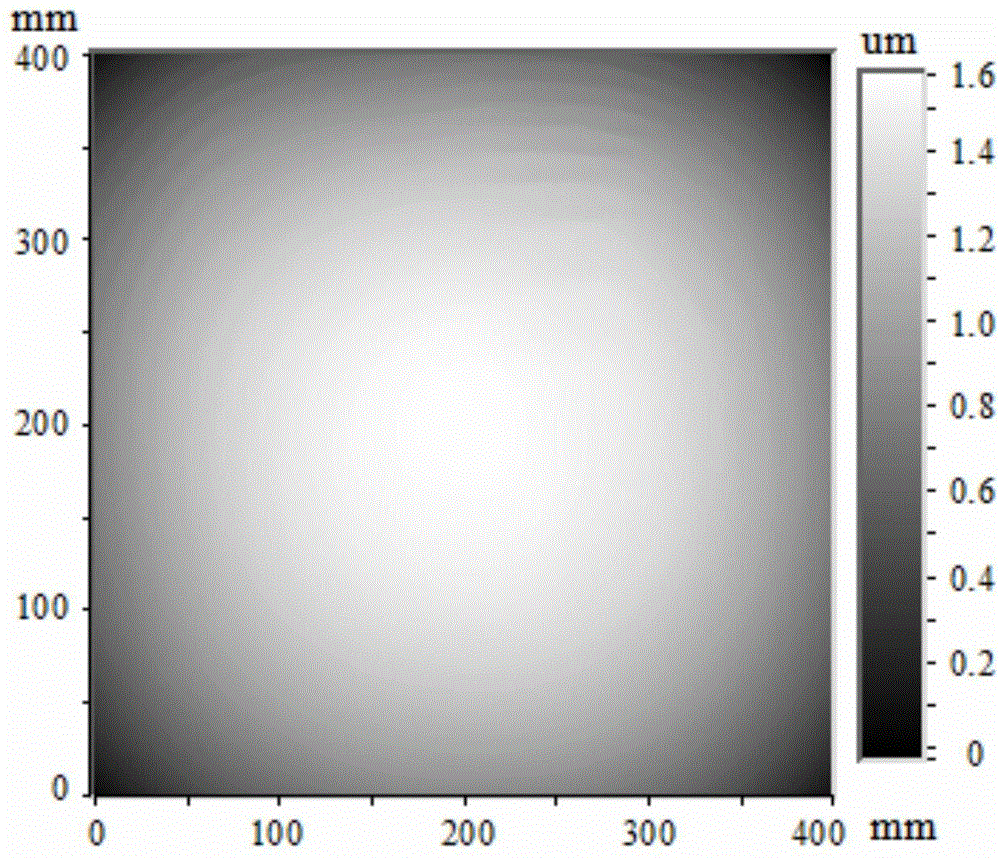

[0040] 1) Obtain the initial surface shape error distribution: use an optical interferometer with a diameter of 800 mm to detect the initial surface shape error of the component to be processed, and obtain the surface shape er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com