Preparation method for conglobated molybdenum disilicide powder

A molybdenum disilicide and powder technology, which is applied in the field of the preparation of agglomerated spherical molybdenum disilicide powder, can solve the problems such as the decrease of product strength, the influence of service performance, restricting the application of molybdenum and its alloys, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

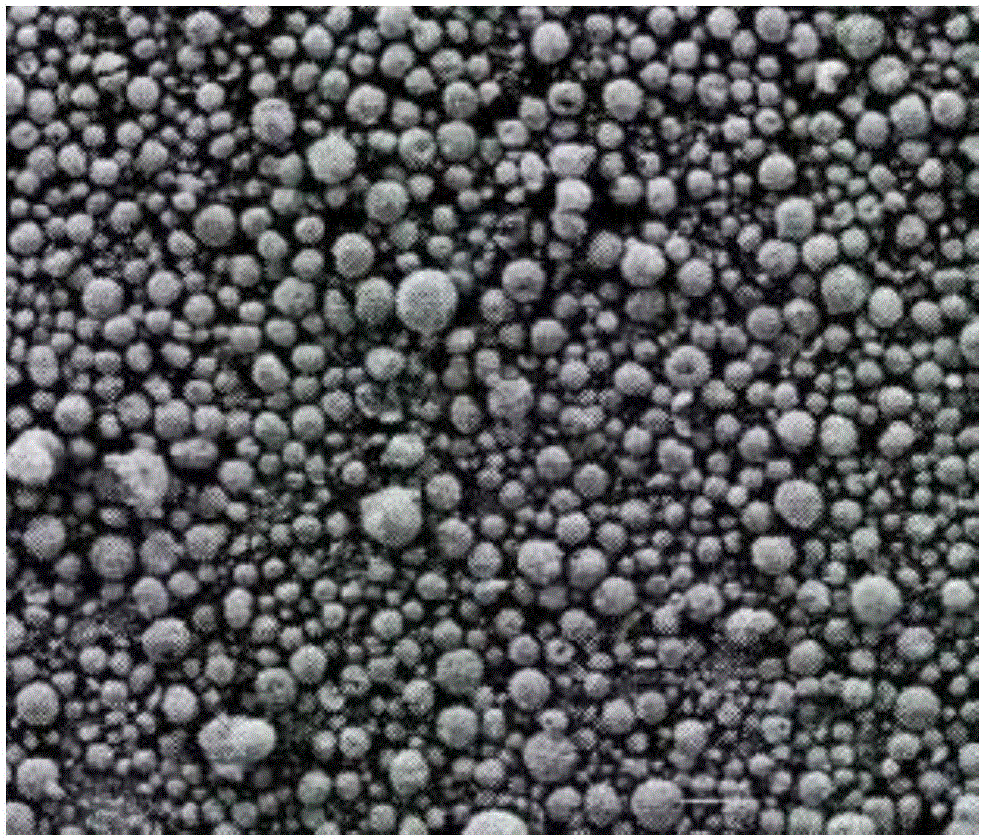

Image

Examples

Embodiment 1

[0020] Preparation method of agglomerated spherical molybdenum disilicide powder

[0021] 1. Disperse molybdenum disilicide powder and dispersant in a solvent to make a suspension, and use an ultrasonic cleaner to disperse fine molybdenum disilicide powder in the liquid medium;

[0022] 2. Add an aqueous solution of 4wt.% polyvinyl alcohol to the liquid medium of dispersed molybdenum disilicide powder to prepare a slurry;

[0023] 3. Spray and granulate the slurry through atomization and granulation equipment to obtain spherical particles. The atomization and drying granulation meets the conditions: centrifugal atomizer speed 20,000rpm, feed temperature 25°C, drying inlet temperature 300°C, drying outlet Temperature 100°C;

[0024] 4. Vacuum heat treatment is carried out on the spherical particles obtained by granulation in a vacuum environment to remove the organic binder in the powder particles and make them densified, so as to improve the powder density and strength. 100 ...

Embodiment 2

[0028] Preparation method of agglomerated spherical molybdenum disilicide powder

[0029] 1. Disperse molybdenum disilicide powder and dispersant in a solvent to make a suspension, and use an ultrasonic cleaner to disperse fine molybdenum disilicide powder in the liquid medium;

[0030] 2. Add an aqueous solution of 3wt.% polyvinyl alcohol to the liquid medium of dispersed molybdenum disilicide powder to prepare a slurry;

[0031] 3. Spray and granulate the slurry through atomization and granulation equipment to obtain spherical particles. The atomization and drying granulation meets the conditions: centrifugal atomizer speed 20,000rpm, feed temperature 20°C, drying inlet temperature 300°C, drying outlet Temperature 100°C;

[0032] 4. Vacuum heat treatment is carried out on the spherical particles obtained by granulation in a vacuum environment to remove the organic binder in the powder particles and make them densified, so as to improve the powder density and strength. 100 ...

Embodiment 3

[0034] Preparation method of agglomerated spherical molybdenum disilicide powder

[0035] 1. Disperse molybdenum disilicide powder and dispersant in a solvent to make a suspension, and use an ultrasonic cleaner to disperse fine molybdenum disilicide powder in the liquid medium;

[0036] 2. Add an aqueous solution of 4wt.% polyvinyl alcohol to the liquid medium of dispersed molybdenum disilicide powder to prepare a slurry;

[0037] 3. The slurry is sprayed and granulated through the atomization granulation equipment to obtain spherical particles, and the atomization drying granulation meets the conditions: the rotational speed of the centrifugal atomizer is 18000rpm, the feed temperature is 25°C, the drying inlet temperature is 300°C, and the drying outlet Temperature 100°C;

[0038] 4. Vacuum heat treatment is carried out on the spherical particles obtained by granulation in a vacuum environment to remove the organic binder in the powder particles and make them densified, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap