Composition for forming plastification material, shoe insole and preparation method of shoe insole

A technology of composition, standard method, applied in the direction of soles, applications, footwear, etc., can solve problems such as increased cost, higher than 2%, and reduced dimensional accuracy of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~5

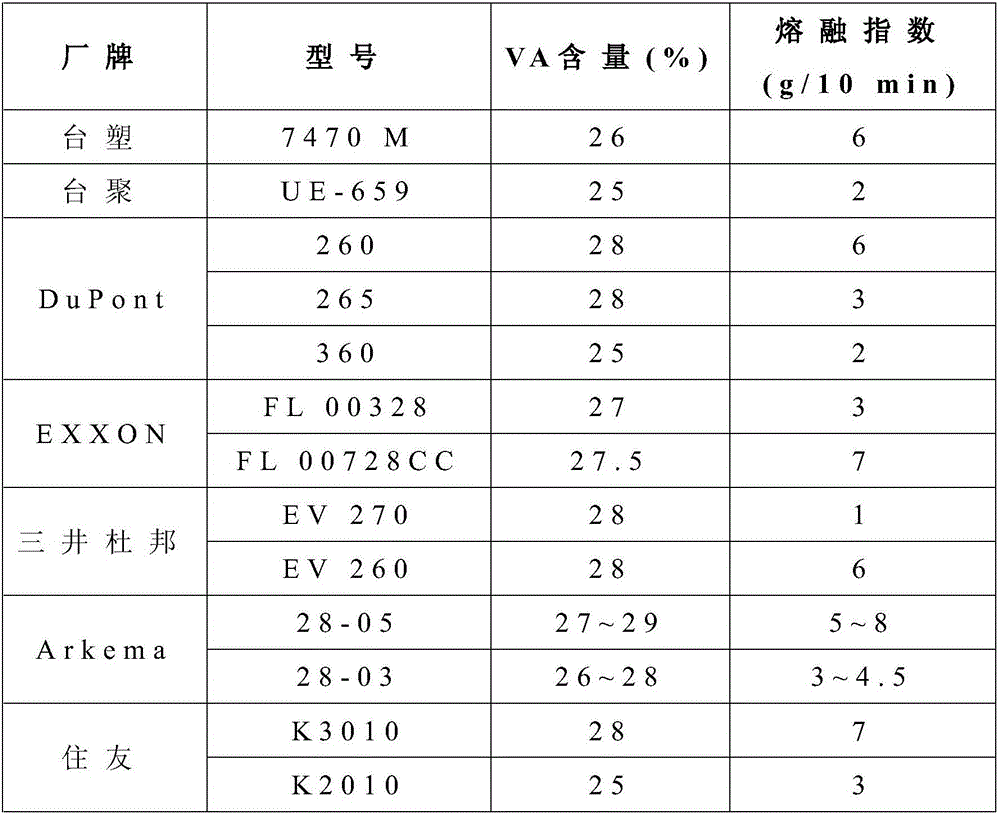

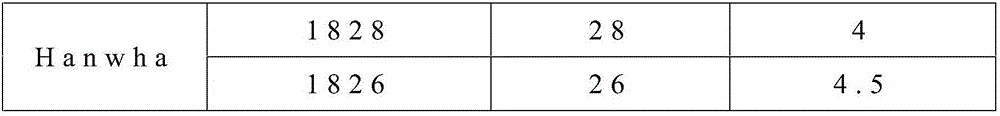

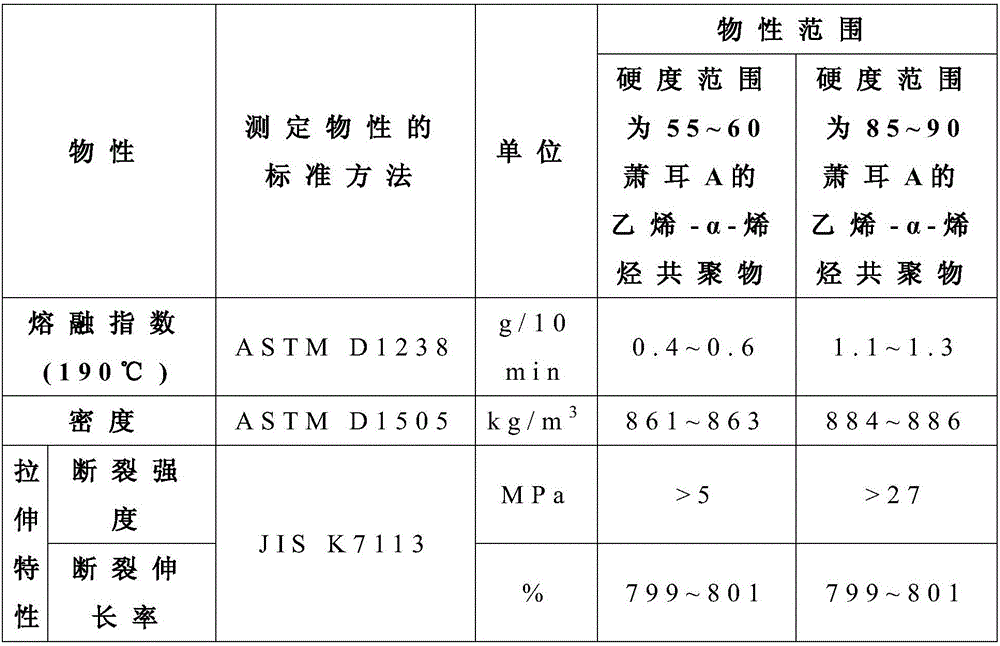

[0052] Preparation of compositions for forming plasticized materials

[0053] After mixing all the ingredients according to the ingredient ratio in the following table 6, the compositions for forming plasticized materials of Examples 1-4 and Comparative Examples 1-3 are prepared; after mixing all the ingredients according to the ingredient ratio in the following table 7, that is The compositions for forming plasticized materials of Examples 5-8 and Comparative Examples 4-5 were prepared. In Table 6 and Table 7, the component content in the polymer component is calculated based on the total weight of the polymer component as 100wt%; the component content in the additive is based on the total weight of the polymer component as 100 parts by weight calculate. Table 6

[0054]

[0055] Table 7

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap