Integral multipurpose water chamber radiator

A technology of water chamber and radiator, applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., can solve the problems of complex installation frame, liquid channeling, thermal fatigue failure, etc., to simplify the installation frame, reduce Thermal stress, effects for design and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

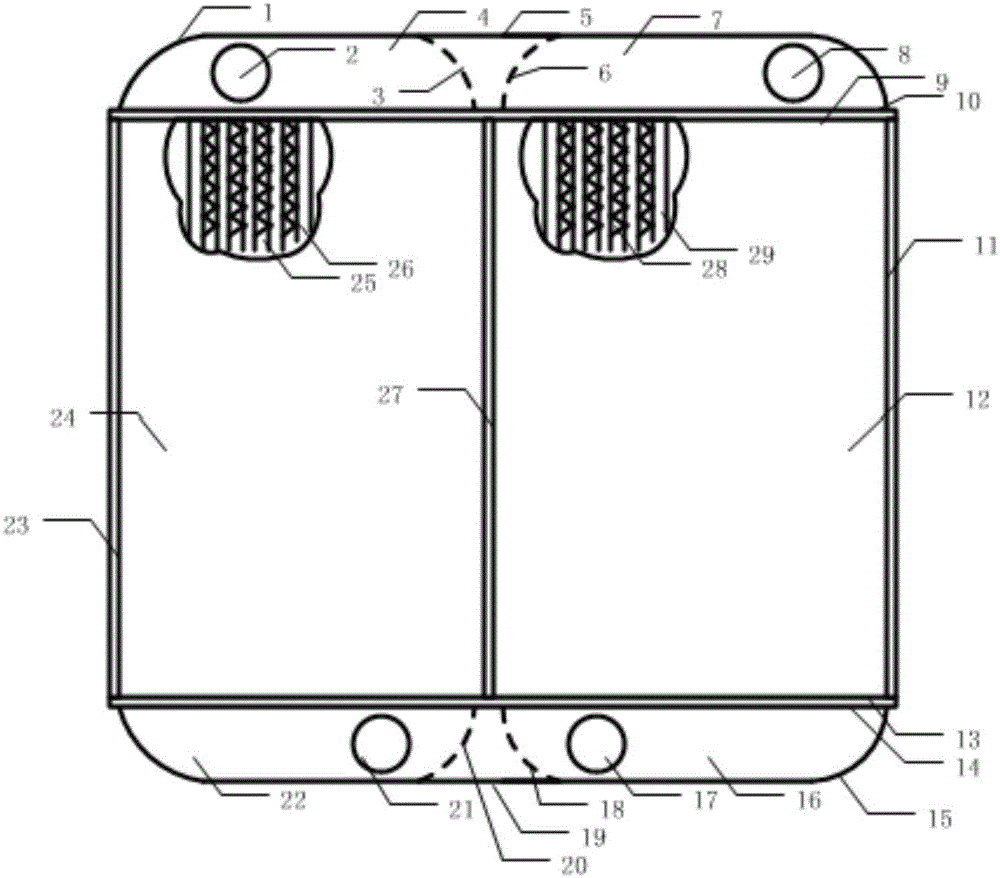

[0029] In this embodiment, the one-piece multi-water chamber is divided into two chambers as an example, but the number of chambers is not limited to two chambers. like Figure 1 to Figure 8 As shown in the figure, the integrated multi-water chamber radiator of the present invention includes an integrated multi-purpose water inlet chamber 1, a water inlet of the left chamber of the water inlet chamber 2, a wall plate of the left chamber of the water inlet chamber 3, a left chamber of the water inlet chamber 4, Water inlet chamber side wall 5, water inlet chamber right chamber wall plate 6, water inlet chamber right chamber 7, water inlet chamber right chamber water inlet 8, water inlet chamber sealing ring 9, water inlet chamber main sheet 10, right Guard plate 11, core right sub-module 12, water outlet chamber sealing ring 13, water outlet chamber main sheet 14, integrated multi-purpose water outlet chamber 15, water outlet chamber right chamber 16, water outlet chamber right...

Embodiment 2

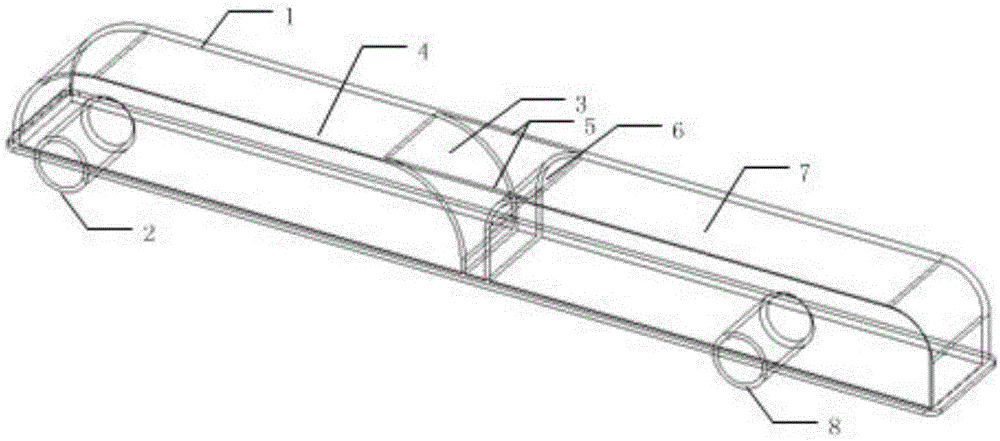

[0034] This embodiment is a structural example of an integrated multi-purpose water inlet chamber of an integrated multi-purpose water chamber radiator.

[0035] like figure 2 As shown, the integrated multi-purpose water inlet chamber 1 of the present invention is integrally formed and divided into a left chamber 4 of the water inlet chamber and a right chamber 7 of the water inlet chamber. The two chambers are not connected to each other, and the tops are not connected. The side walls 5 of the chamber are connected into one body. The left chamber 4 of the water inlet chamber is provided with a water inlet 2 of the left chamber of the water inlet chamber, and the right chamber 7 of the water inlet chamber is provided with a water inlet 8 of the right chamber of the water inlet chamber. The left chamber wall plate 3 of the water inlet chamber and the right chamber wall plate 6 of the water inlet chamber are separated by a distance of 3-8 mm near the end of the main sheet 10 o...

Embodiment 3

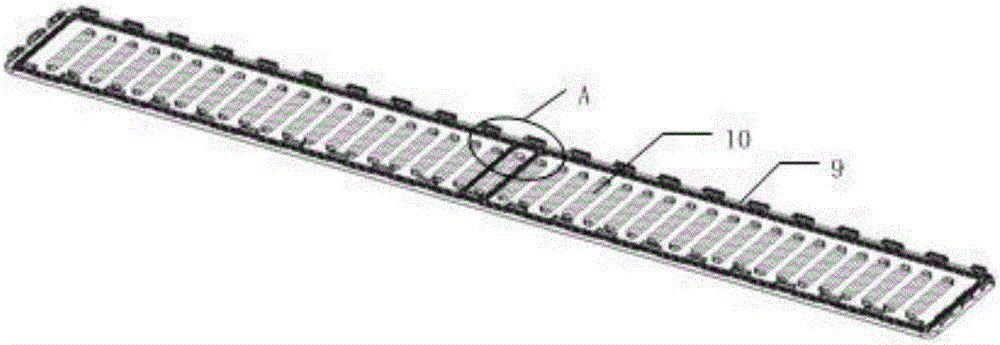

[0037] This embodiment is a structural example of the water inlet chamber main sheet and the water inlet chamber sealing ring of the integrated multi-water chamber radiator.

[0038] like image 3As shown, the water inlet chamber main sheet 10 is provided with a water inlet chamber sealing ring groove 30 for placing the sealing ring, the sealing ring grooves are all connected, and the water inlet chamber main sheet 10 is punched with independent flanges according to the structure of the water inlet chamber. 31. An integrated multi-purpose water inlet chamber is equipped with a water inlet chamber main sheet 10 and an integral water inlet chamber sealing ring or two independent water inlet chamber sealing rings.

[0039] like Figure 4 Shown is a schematic diagram of the partial structure of the sealing ring groove punched out by the main sheet 10 of the water inlet chamber at the corresponding positions of the two wall plates between the chambers.

[0040] like Figure 5 S...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap