Mechanical arm and substrate grabbing method

A technology of robotic arms and manipulators, applied in the directions of manipulators, conveyor objects, electrical components, etc., can solve problems such as scratching the substrate, and achieve the effect of ensuring the safety of picking and placing and reducing the risk of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

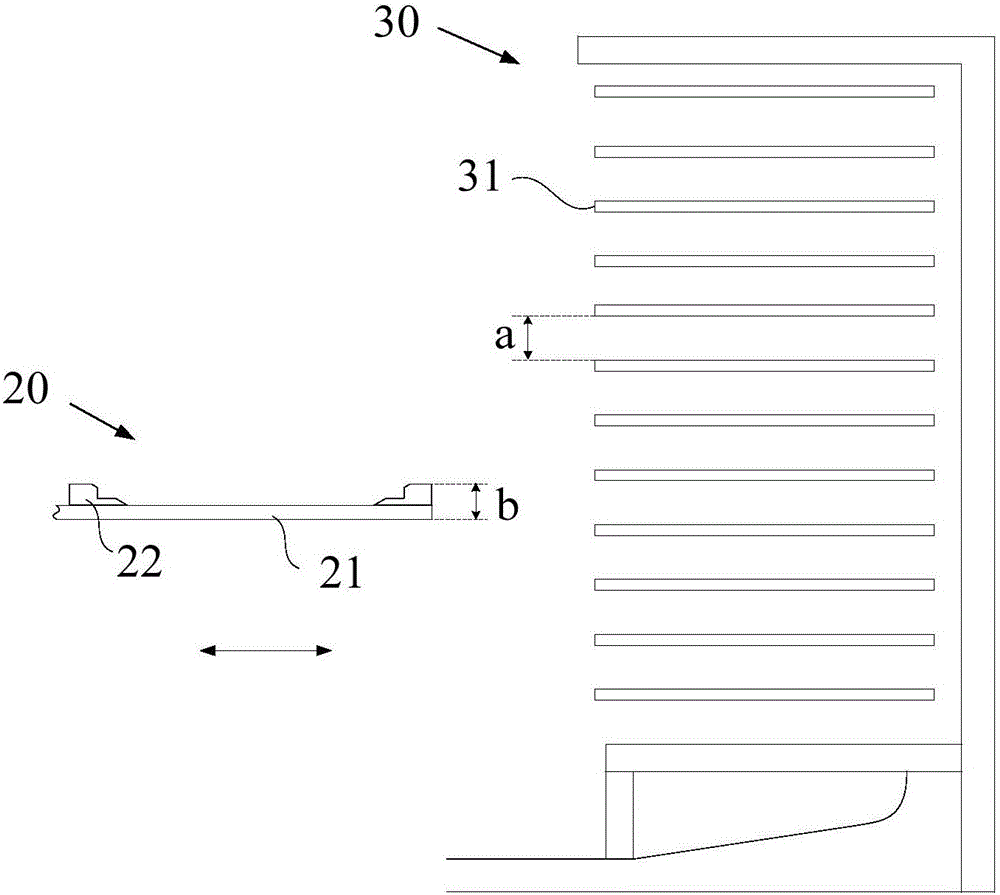

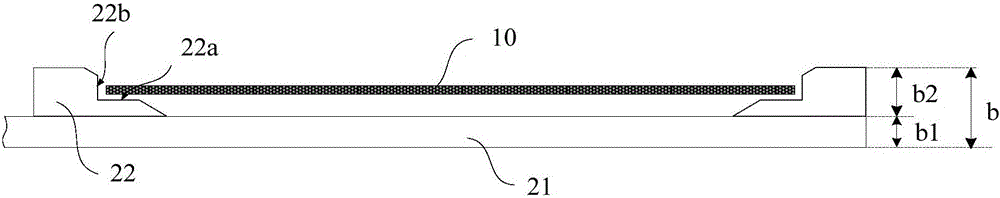

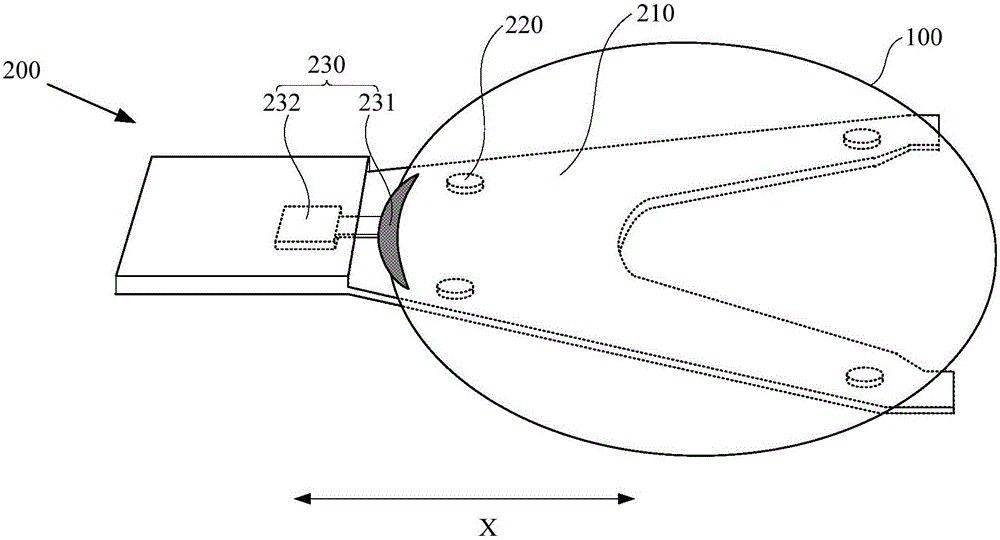

[0036] image 3 It is a schematic structural diagram of the mechanical arm in Embodiment 1 of the present invention, Figure 4 It is a schematic structural diagram of a robot arm carrying a substrate in Embodiment 1 of the present invention. In this embodiment, the substrate is a wafer. combine image 3 and Figure 4 As shown, the robotic arm 200 includes: a robotic disc 210 , a contact pad 220 and an adsorption device 230 disposed on the robotic disc 210 . Wherein, the manipulator plate 210 carries the weight of the entire substrate 100, which has a certain thickness c1; the contact pad 220 is in contact with the substrate 100 and supports the substrate to reduce the contact area between the substrate 100 and the manipulator plate 210, and in consideration On the basis of the deformation of the substrate 100, the contact pad 220 also needs to have a certain thickness c2; the adsorption device 230 is used to adsorb and fix the substrate 100 to prevent the substrate from sha...

Embodiment 2

[0043] Figure 5 It is a structural schematic diagram of the robot arm in the second embodiment of the present invention. Such as Figure 5 As shown, the difference from Embodiment 1 is that in this embodiment, the adsorption device 230 ′ is fixed on the manipulator plate 210 , and fixes the substrate 100 by adsorbing the lower surface of the substrate 100 , wherein the adsorption The thickness of device 230 ′ is less than the thickness of contact pad 220 . That is, in this embodiment, since the adsorption device 230' is used to adsorb the lower surface of the substrate 100, when the contact pad 220 supports the substrate 100, the adsorption device 230' is correspondingly located below the substrate 100, therefore Therefore, fixing the adsorption device 230 ′ directly on the manipulator plate 210 can still achieve the function of absorbing the substrate 100 , thus making the structure of the robot arm 200 ′ simpler. In addition, since the thickness of the adsorption device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com