Power distribution network SYG copper and aluminum transition equipment wire clamp

A technology for equipment wire clips and distribution networks, which is applied to circuits, electrical components, conductive connections, etc., can solve problems such as lower customer satisfaction, lower power supply reliability, and accelerated electrochemical reactions. The effect of reducing the influence of transition resistance and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

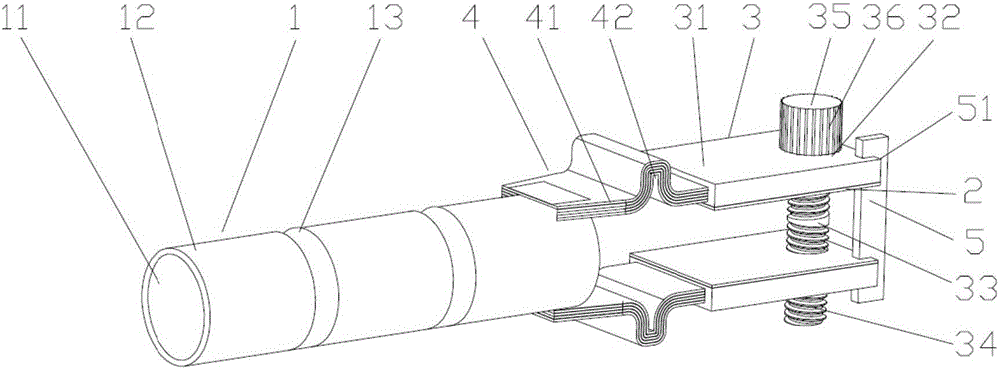

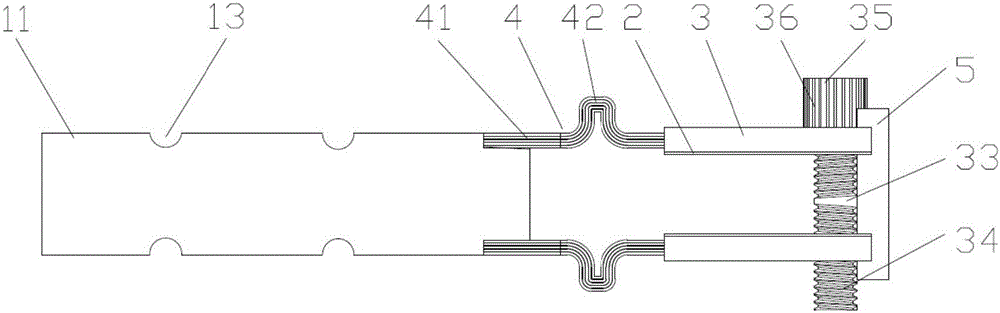

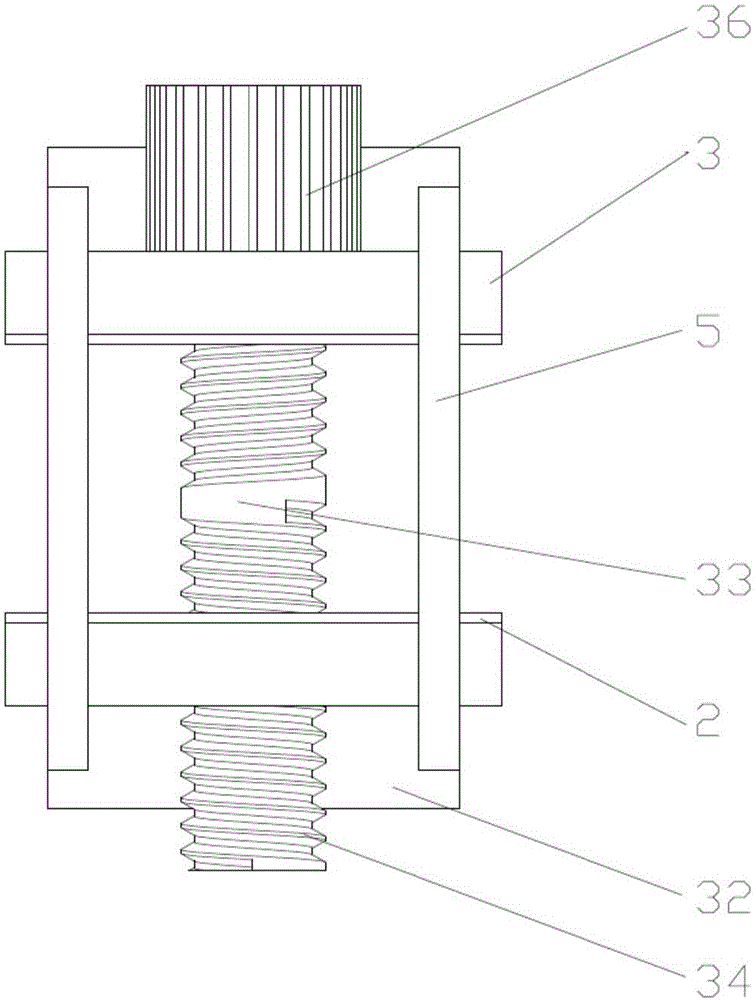

[0026] Such as Figure 1 to Figure 3 Shown is the first embodiment of the SYG copper-aluminum transition equipment clamp of the distribution network of the present invention, including the first connecting piece 1 connected to the bus down conductor of the substation and two sets of second connecting pieces connected to the electrical equipment 2. The two sets of second connectors 2 are arranged symmetrically on both sides of the center line of the first connector 1, and the second connector 2 is provided with a clamping member 3; one end of the clamping member 3 is connected to the first connector 1 connect.

[0027] Specifically, the first connector 1 is a hollow cylinder structure with one end open and the other closed, and the second connector 2 is a copper sheet structure with a flat surface; the first connector 1 is composed of a conductive inner layer structure 11 and an insulating outer layer structure 12 The inner layer structure 11 is tightly connected with one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com