Umbrella-type hydro-generator shaft insulating structure

A technology of hydro-generator and insulating structure, which is applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of difficult online real-time monitoring, etc., and achieve the effects of high rigidity, reduced difficulty, and prevention of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] As a preferred embodiment of the present invention, this embodiment discloses:

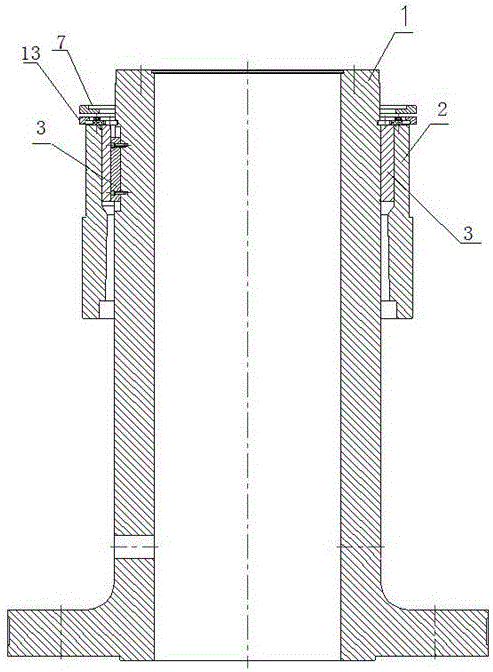

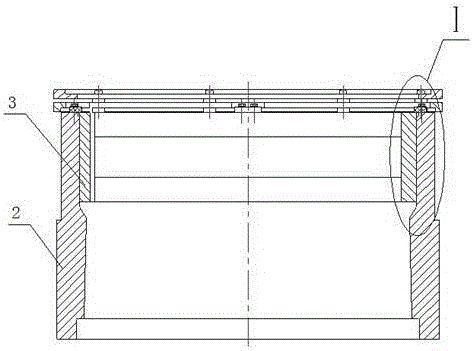

[0030] An umbrella-type hydraulic generator shaft insulation structure, including an upper shaft 1 and a sliding rotor 2, a first insulating layer 4, a conductive layer 5 and a second insulating layer 6 are arranged between the upper shaft 1 and the sliding rotor 2, the The second insulating layer 6 is wrapped around the conductive layer 5 . In this embodiment, the first insulating layer 4 and the second insulating layer 6 can be made of conventional insulating materials, such as insulating pads.

Embodiment 2

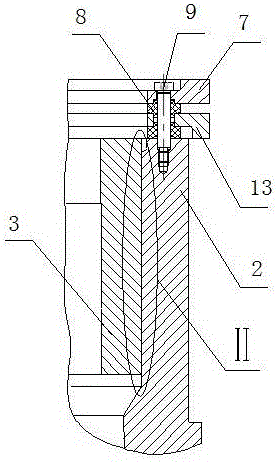

[0032] As another preferred embodiment of the present invention, this embodiment discloses: an umbrella type hydroelectric generator shaft insulation structure, including an upper end shaft 1 and a sliding rotor 2, and a second An insulating layer 4 , a conductive layer 5 and a second insulating layer 6 , the second insulating layer 6 wraps around the conductive layer 5 . In this embodiment, the first insulating layer 4 and the second insulating layer 6 can be selected from conventional insulating materials, such as insulating pads; also include an upper measuring ring 7 and a lower measuring ring 13, the upper measuring ring 7 and the lower measuring ring 13 is fixed on the sliding rotor 2 through insulating pads 8 and bolts; the conductive layer 5 is connected to the lower measuring ring 13 through lead wires 10; the sliding rotor 2 is electrically connected to the upper measuring ring 7 through bolts.

Embodiment 3

[0034] As another preferred embodiment of the present invention, this embodiment discloses:

[0035] An umbrella-type hydraulic generator shaft insulation structure, including an upper shaft 1 and a sliding rotor 2, a first insulating layer 4, a conductive layer 5 and a second insulating layer 6 are arranged between the upper shaft 1 and the sliding rotor 2, the The second insulating layer 6 is wrapped on the conductive layer 5; a sleeve 3 is also arranged between the upper shaft 1 and the sliding rotor 2, and the sleeve 3 is arranged between the first insulating layer 4 and the upper shaft 1 ; The first insulating layer 4 is wrapped around the sleeve 3; the sleeve 3 is connected with the upper shaft 1 through a key; the sliding rotor 2 and the sleeve 3 are connected together through an interference fit.

[0036] In this embodiment, the first insulating layer 4, the conductive layer 5 and the second insulating layer 6 can be stacked layer by layer or wrapped layer by layer. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com