Arc bent pipe inner wall machining tool

A technology for processing machine tools and pipe bends, which is applied in the field of processing machine tools for the inner wall of arc bend pipes, can solve the problems of poor processing quality, long processing time, and low efficiency, and achieve the effect of overcoming poor cutting stability and a wide range of processing sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and specific embodiments.

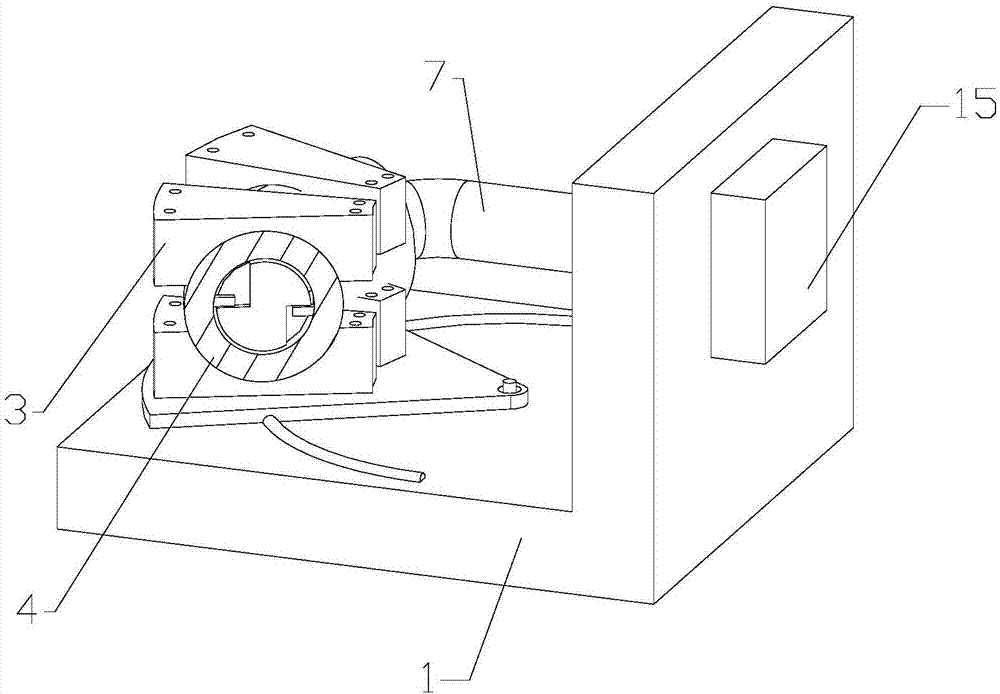

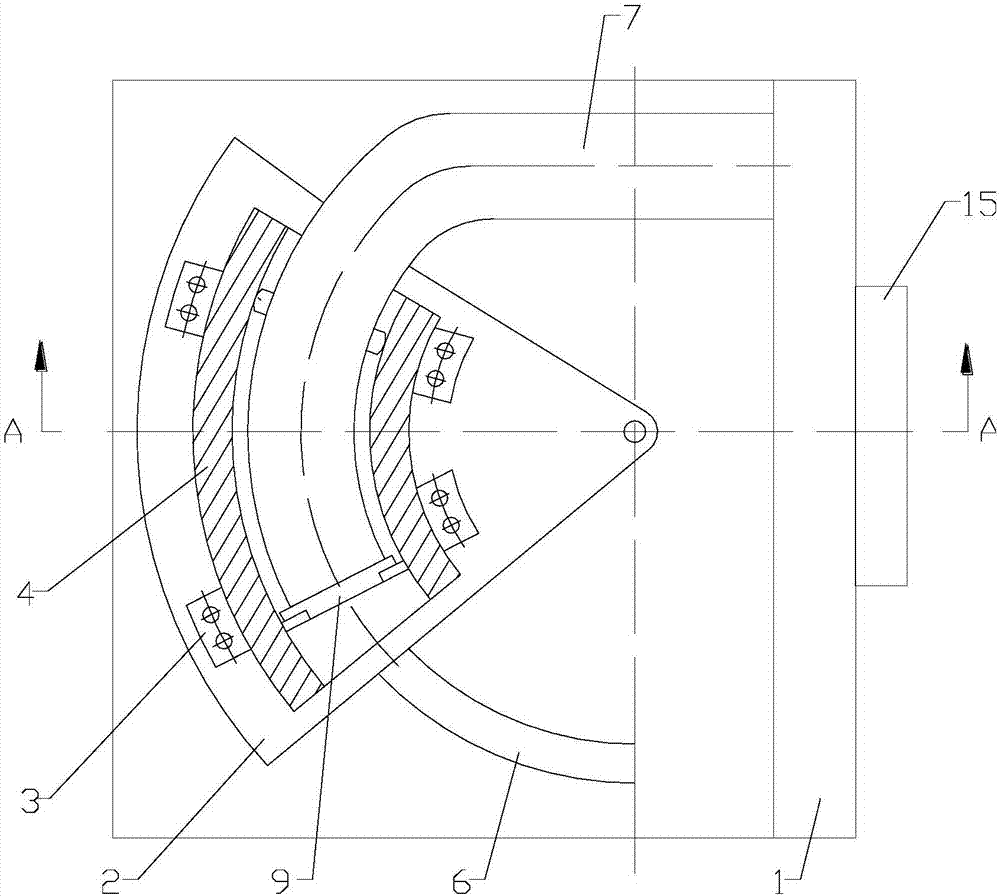

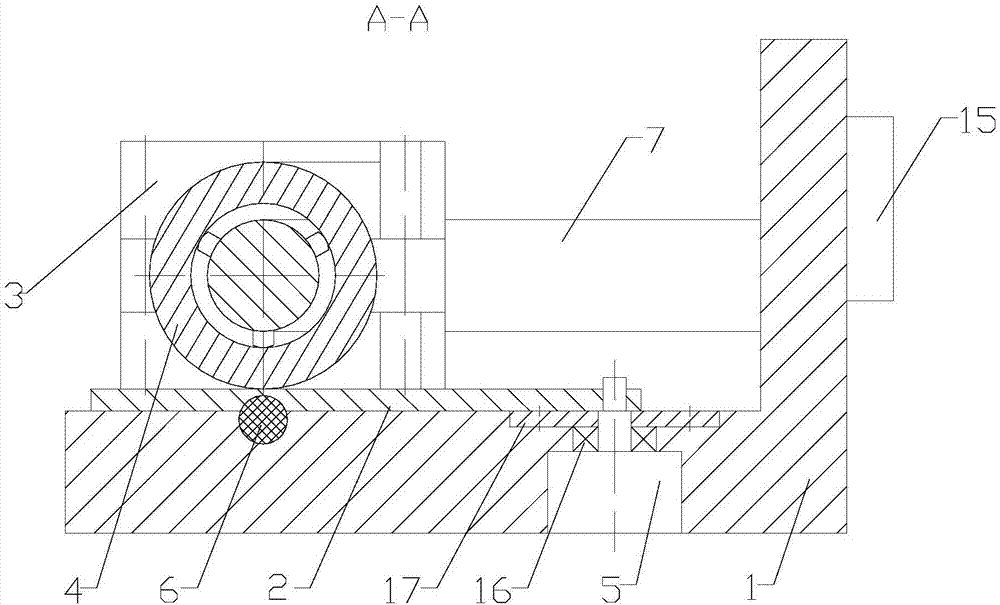

[0021] The invention provides a machine tool for processing the inner wall of a circular arc elbow, such as figure 1 , figure 2 with image 3 As shown, it includes a bed 1, which is composed of a horizontal part and a vertical part. The vertical part is fixed above one end of the horizontal part. The upper surface of the horizontal part of the bed 1 is provided with a rotating platform 2, which is connected to the bed. The body 1 is rotatably connected, and the rotating platform 2 is fan-shaped. An angle motor 5 is fixed in the horizontal part of the bed 1. The output shaft of the angle motor 5 extends from the horizontal part of the bed 1 and is connected to the center of the rotating platform 2. The angle motor 5 A first bearing 16 and a first bearing end cover 17 are provided on the output shaft at the connection point. The upper surface of the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com