A Micro Throttling Refrigerator in Liquid Helium Temperature Zone

A throttling refrigerator and temperature zone technology, applied in refrigerators, refrigeration and liquefaction, modification using liquid cooling, etc., can solve problems such as experimental research on micro throttling refrigerators that have not yet been seen, and reduce processing risks and structure. The effect of compact, simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

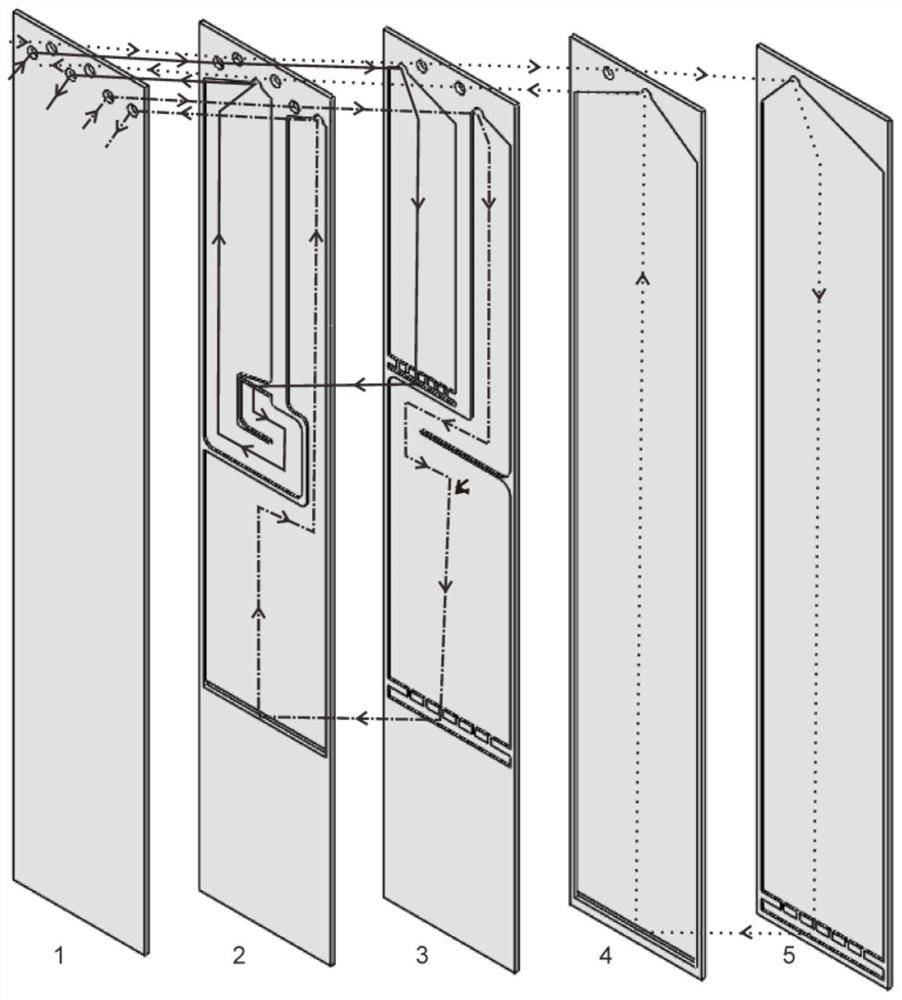

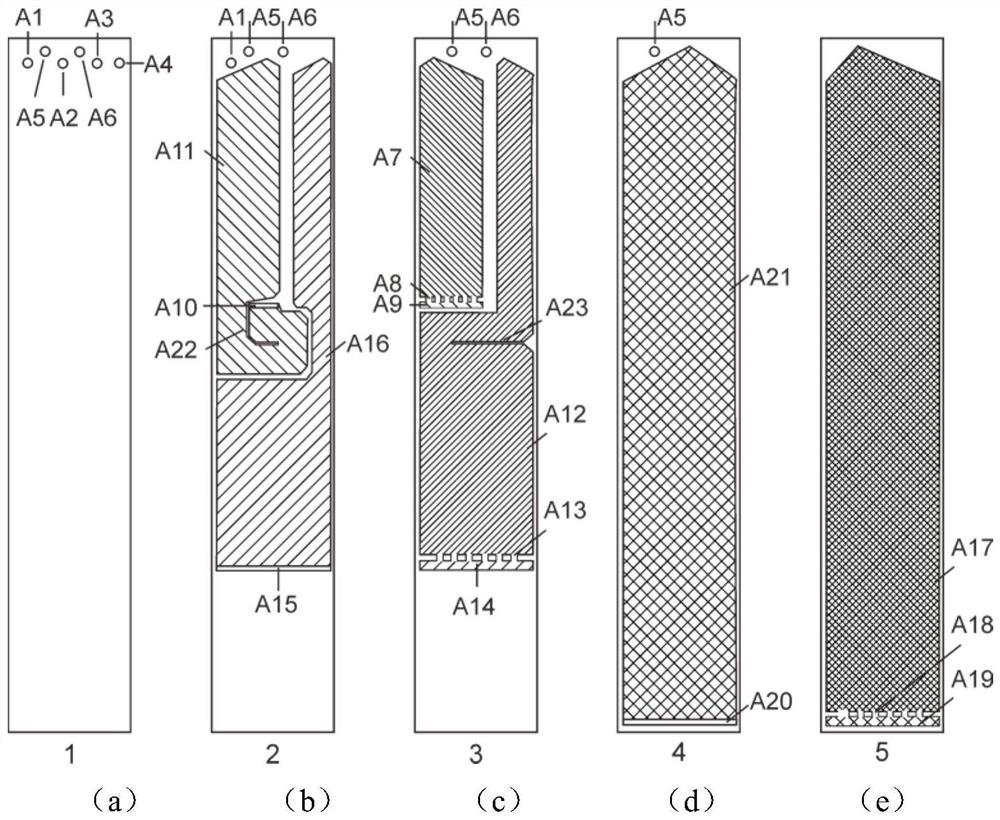

[0032] see figure 1 , figure 2 , The liquid helium temperature zone micro-throttling refrigerator A of the first embodiment of the present invention is welded into an integral structure by sequentially stacking five layers of substrates 1-5.

[0033] Substrate 1 acts as a cover to seal the rest of the substrates. Substrates 2 and 3 form a first-stage refrigeration circulator and a second-stage refrigeration circulator. Substrates 4 and 5 form a third-stage refrigeration circulator. The first-stage refrigeration cycle The device is located between the substrate 1 and the three-stage refrigeration circulator. in,

[0034] There are six through holes on the top of the substrate 1 as primary working fluid inlet A1, secondary working fluid inlet A3, tertiary working fluid inlet A5, primary working fluid outlet A2, secondary working fluid outlet A4 and tertiary working fluid Quality export A6.

[0035] The top of the substrate 2 is provided with three through holes respectively...

Embodiment 2

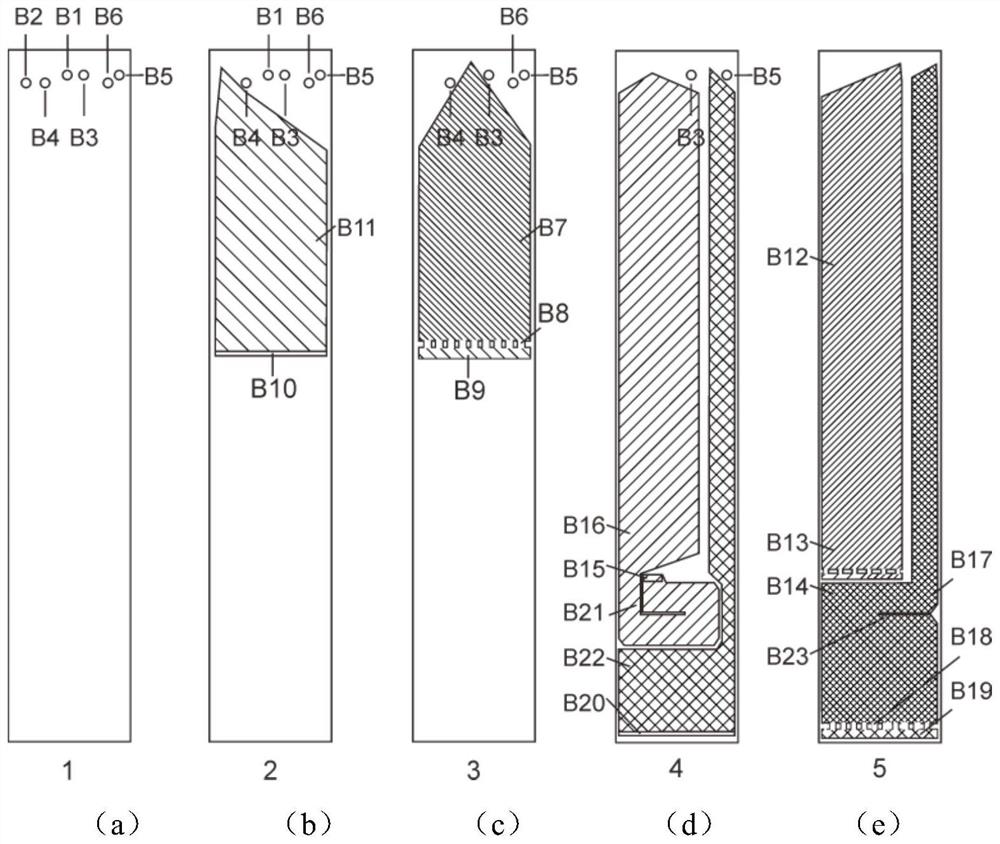

[0051] image 3 It is a schematic diagram of the internal structure of the micro throttle refrigerator B in the liquid helium temperature zone of the second embodiment of the present invention. The throttle refrigerator B is welded into an integral structure by successively stacking five layers of substrates 1 to 5. The substrate 2 and the substrate The sheet 3 constitutes a primary refrigeration circulator, and the substrate 4 and substrate 5 constitute a secondary refrigeration circulator and a tertiary refrigeration circulator. in,

[0052] There are six through holes on the top of the substrate 1, respectively serving as the first-level working fluid inlet B1, the second-level working fluid inlet B3, the third-level working fluid inlet B5, the first-level working fluid outlet B2, the second-level working fluid outlet B4 and the third-level working Quality export B6.

[0053] The top of the substrate 2 is provided with five through holes as the first-level working fluid i...

Embodiment 3

[0059] Figure 4 It is a schematic diagram of the internal structure of a micro-throttling refrigerator C in a liquid helium temperature zone according to Embodiment 3 of the present invention. The throttling refrigerator C is welded into an integral structure by sequentially stacking three layers of substrates 1-3.

[0060] Substrate 1 acts as a cover to seal the rest of the substrates, and substrates 2 and 3 constitute a primary refrigeration circulator, a secondary refrigeration circulator and a tertiary refrigeration circulator. in,

[0061] There are six through holes on the top of the substrate 1, which are used as the first-level working fluid inlet C1, the second-level working fluid inlet C3, the third-level working fluid inlet C5, the first-level working fluid outlet C2, the second-level working fluid outlet C4 and the third-level working fluid. Quality export C6.

[0062]The top of the substrate 2 is provided with three through holes as the first-level working flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com