Flexible honing and reaming device suitable for precision machining of valve element hole of hydraulic multi-way valve

A precision machining, multi-way valve technology, used in metal processing equipment, grinding/polishing safety devices, control of workpiece feed movement, etc. The effect of high processing precision, high filtering precision and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

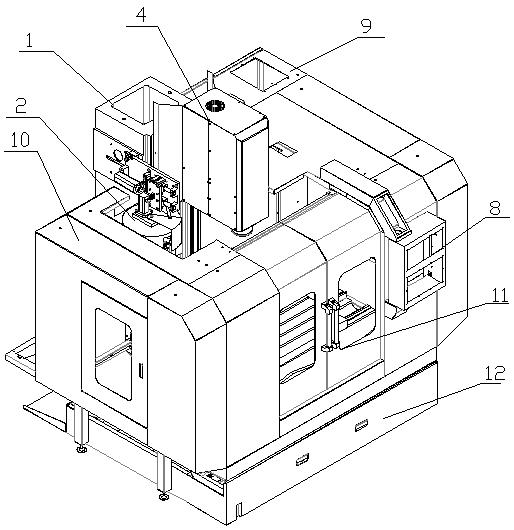

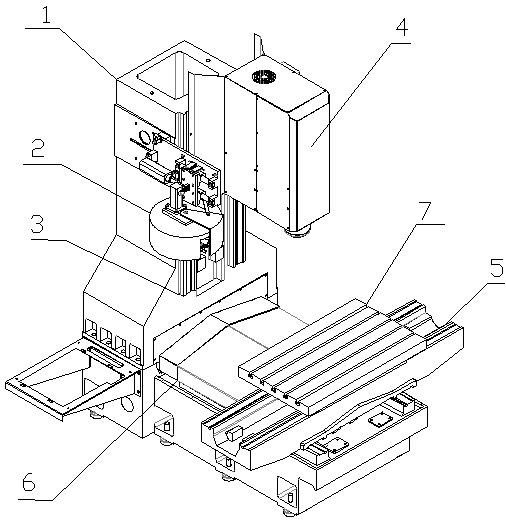

[0024] combine figure 1 and figure 2 As shown, a flexible honing device suitable for precision machining of the spool hole of a hydraulic multi-way valve, the bed 6 is fixed on the bed base 12, and the left end of the bed 6 is fixed with a Z-axis column 1 . The upper end of the Z-axis column 1 is slidably connected to the Z-axis spindle 4 , and the side of the Z-axis column 1 is fixed with a bamboo hat type tool magazine 2 and a Renishaw optical probe system 3 .

[0025] The X / Y axis cross slide table 5 is slidably installed on the bed 6, and the X / Y axis cross slide table 5 has an exchange pallet 7 for installing workpieces. Specifically: there is an X-axis slide rail on the bed 6, and the X / Y-axis cross slide 5 includes a sliding seat slidably installed on the X-axis slide rail of the bed 6; the exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com