An injection mold with adjustable opening stroke

An injection mold and stroke technology, applied in the field of injection molds, can solve the problems of high cost of mold opening, poor control of force, complicated structure of control mechanism, etc., and achieve the effect of slow separation, easy removal, and favorable molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

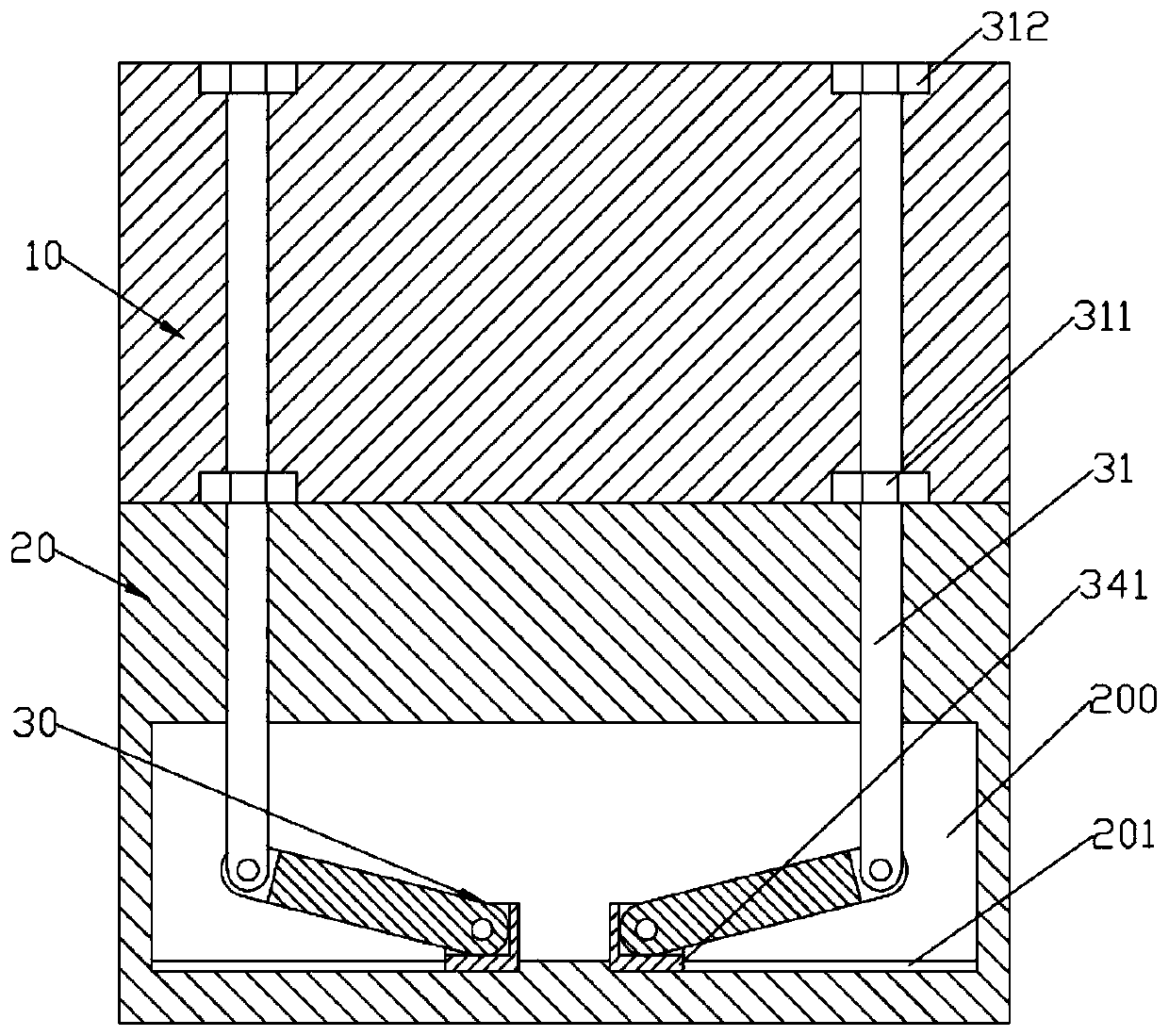

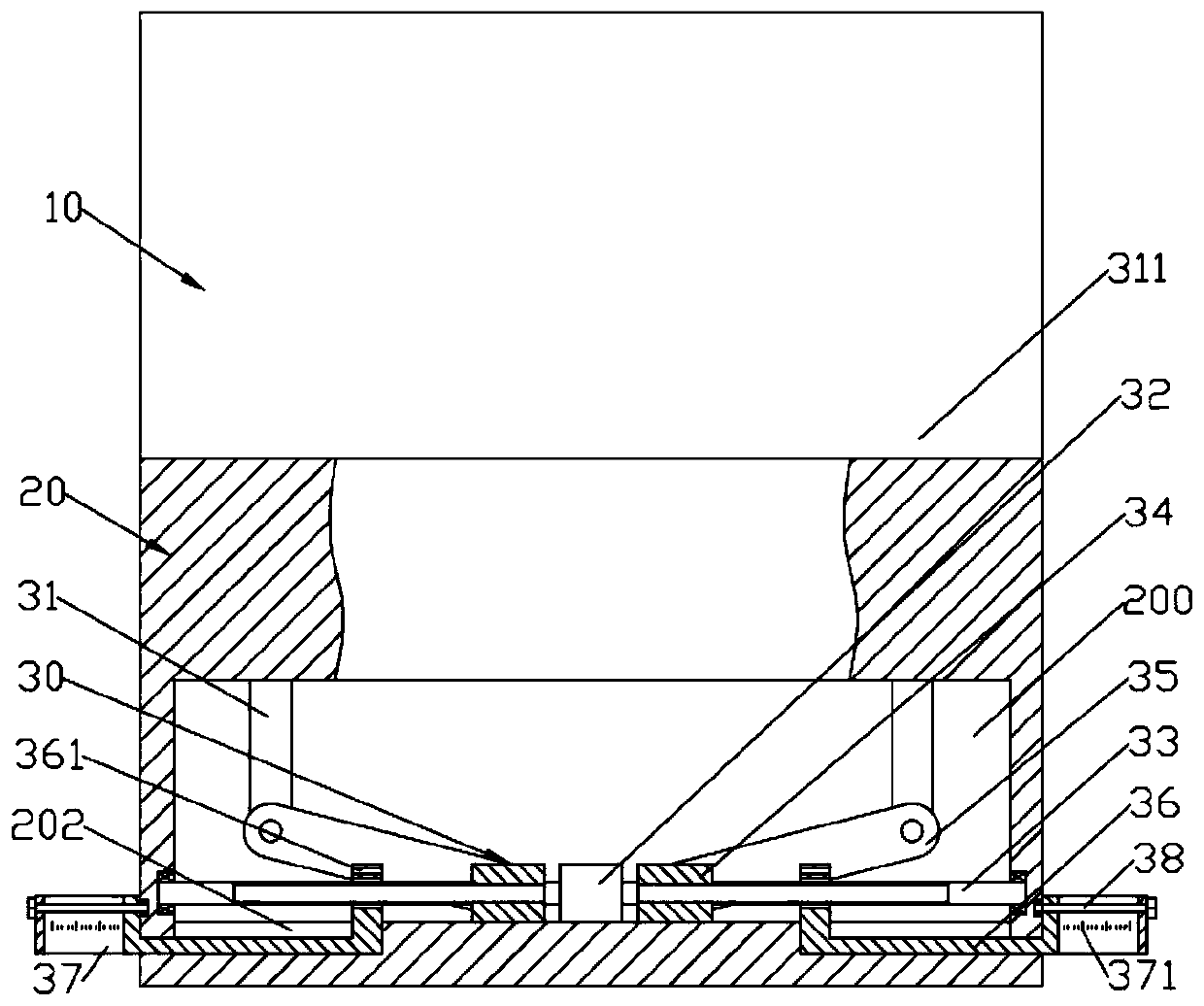

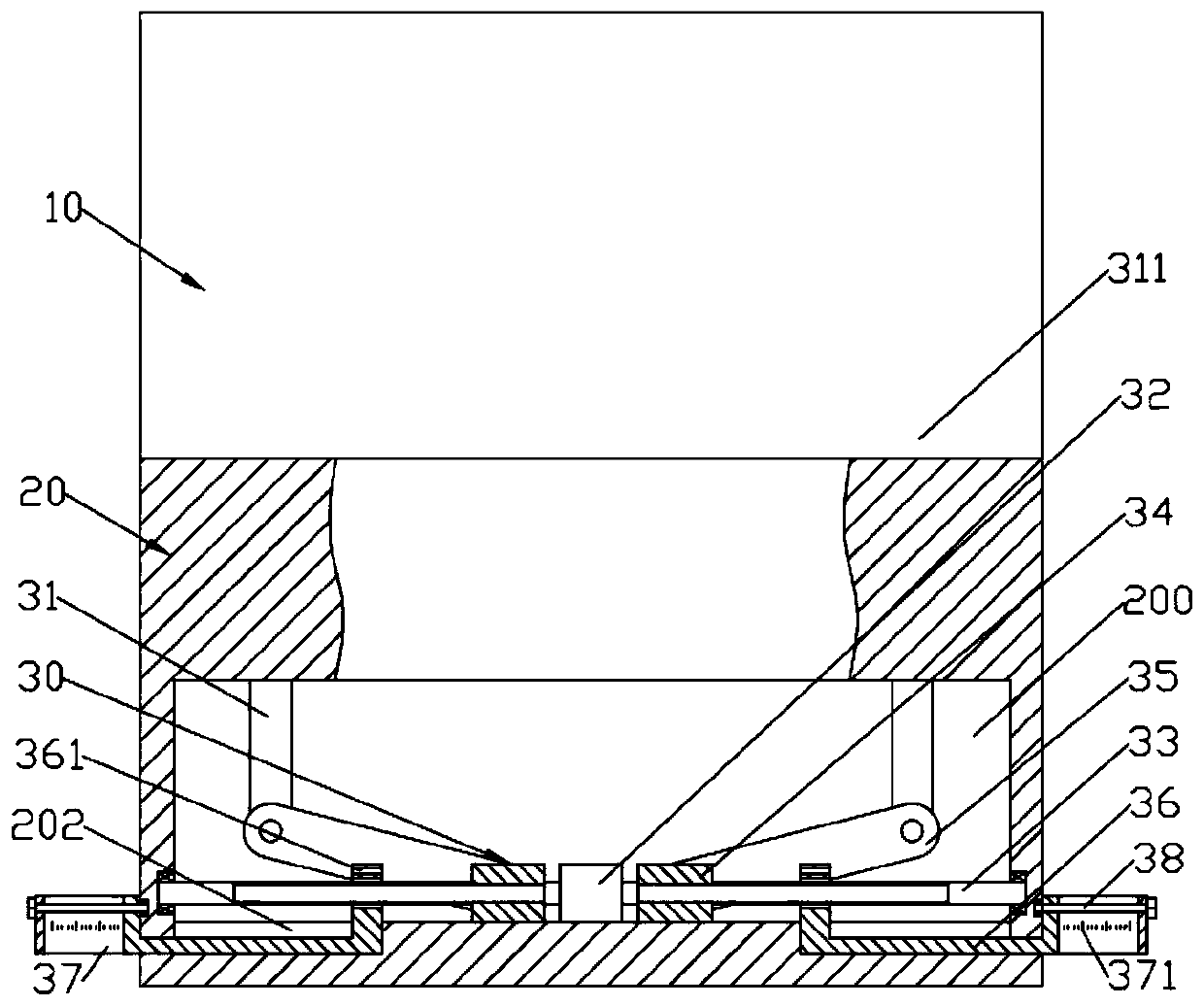

[0014] Such as figure 1 , figure 2 As shown, an injection mold with adjustable mold opening stroke includes an upper mold 10, a lower mold 20 and a mold opening device 30; the lower part of the lower mold 20 is formed with a rectangular driving groove 200; the upper side wall of the driving groove 200 is lifted and set There are two pairs of left and right symmetrical guide rods 31; the upper end of the guide rod 31 is fixedly connected with the upper mold 10; the lower end of the guide rod 31 is hinged with a central connecting rod 35; the mold opening device 30 includes a double-head motor 32; the double-head motor 32 is fixed on The drive threaded rod 33 is fixedly connected to the center of the lower side wall of the drive groove 200 and the output shafts on the left and right sides; the other end of the drive threaded rod 33 is pivotally connected to the corresponding side wall of the drive groove 200; the drive threaded rod 33 is screwed There is a mobile support seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com