Method for utilizing PDPAEMA modified shape memory polymers to regulate and control surface permeability

A technology of memory polymer and surface infiltration, which is applied in the field of regulating surface wettability by modifying shape memory polymer with PDPAEMA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

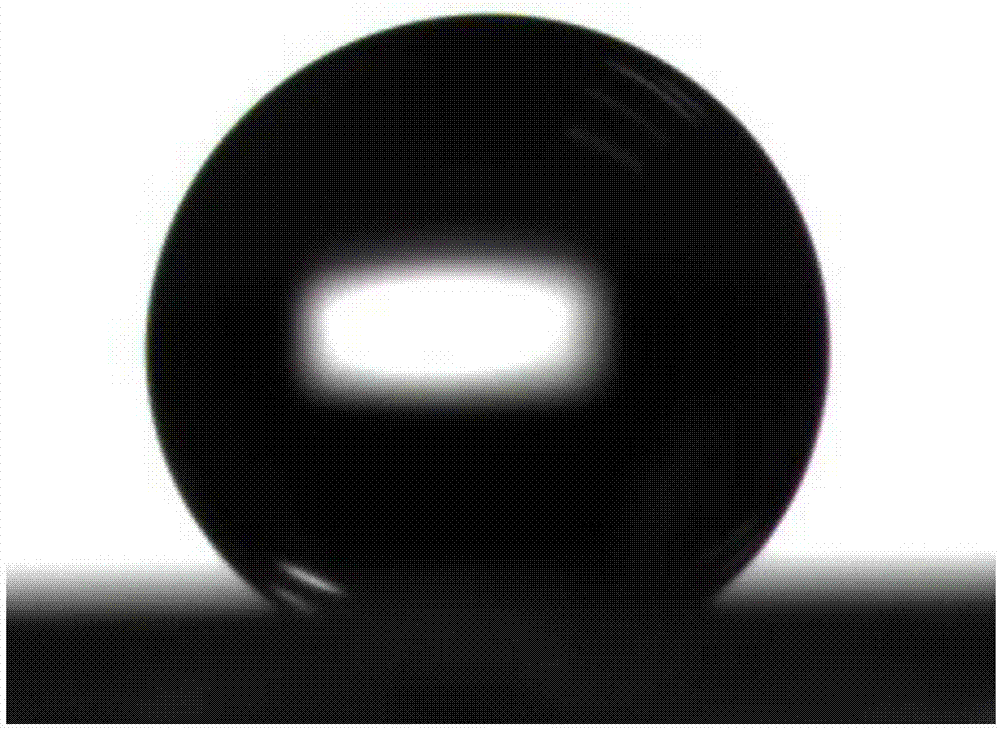

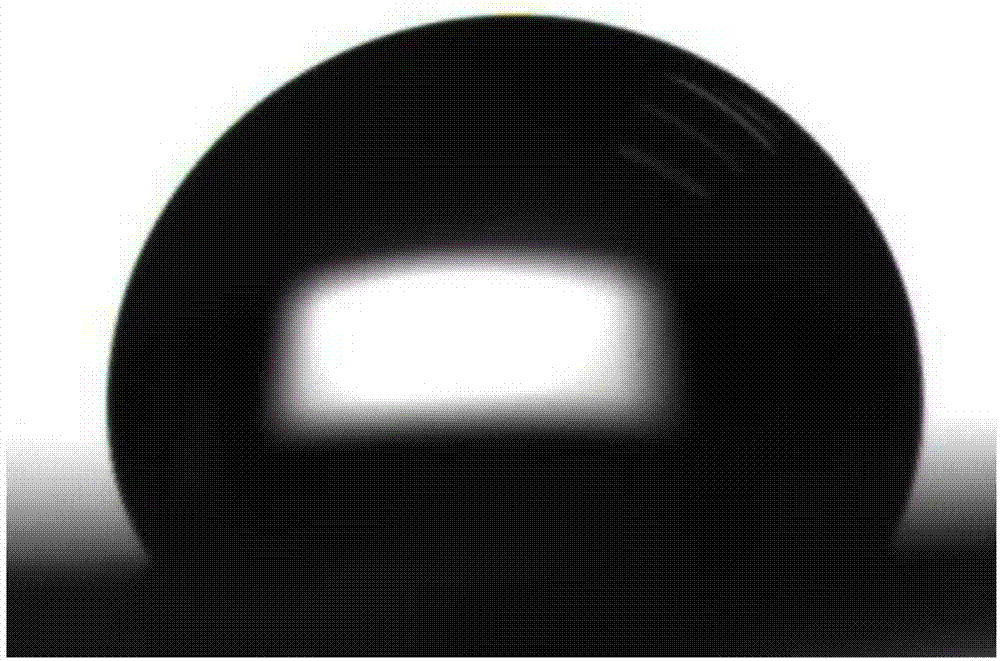

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment 1: What this embodiment describes is a method for regulating surface wettability by using PDPAEMA modified shape memory polymer, the method includes the following steps:

[0022] Step 1: use photolithography to etch the silicon wafer, so that the surface of the silicon wafer presents different arrays, the length × width of the etched silicon wafer array is 10 μm × 10 μm, the array spacing is 5 μm-30 μm, and the array height is 10-30μm;

[0023] Step 2: Use polydimethylsiloxane to shape the silicon wafer, the weight ratio of silicone rubber to curing agent is 90-150:10, the curing temperature is 65-100°C, and demold after curing to obtain the silicon wafer Array reversed PDMS template;

[0024] Step 3: Use the PDMS template to shape the shape-memory epoxy resin microarray, use epoxy resin and curing agent, and mix the glue according to the weight ratio of 0.01-0.017:1, and cure it at 60-120°C for 10 -24h, demoulding to obtain the shape memory epoxy ...

specific Embodiment approach 2

[0027] Specific embodiment 2: The method of using PDPAEMA modified shape memory polymer to regulate surface wettability described in specific embodiment 1, in step 3, the epoxy resin is epoxy resin E51 or epoxy resin E44, and the curing The agent is n-octylamine, dodecylamine or m-xylylenediamine.

specific Embodiment approach 3

[0028]Specific embodiment three: the method of using PDPAEMA to modify shape memory polymers for surface wettability regulation described in specific embodiment one, in step four, the silane coupling agent is 3 aminopropylmethoxysilane or 3 aminopropyl Ethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com