Preparation method for furfural extract oil sulfonate used for oil displacement

A technology for extracting oil and oil sulfonate from furfural, which is applied to chemical instruments and methods, compositions of drilling holes, etc., can solve problems such as poor compatibility, inability to greatly improve oil recovery, inability to achieve ultra-low interfacial tension, and the like, Achieving a good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

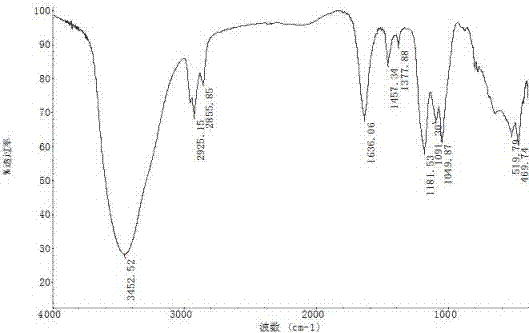

[0020] (1), the preparation of intermediate furfural extraction oil sulfonic acid

[0021] Add the furfural extracted oil into the four-necked bottle, start the stirring, raise the temperature to 40°C, and inject SO with a concentration of 5%. 3 Mixed gas for sulfonation reaction, react for 1 hour, stop feeding SO 3 , keep the reaction temperature, aging for 1.5 hours, the intermediate product sulfonic acid is obtained.

[0022] (2), preparation of furfural extraction oil sulfonate

[0023] Control the temperature of the four-neck flask at 35°C, start stirring, slowly add NaOH solution with a concentration of 15% to the intermediate product, adjust the pH value to 8-9, continue stirring for 1 hour, and after removing water and drying, the product furfural is extracted Oil sulfonate.

[0024] (3), interfacial tension test

[0025] Oil displacement system: a system composed of furfural extracted oil sulfonate and coconut oil fatty acid diethanolamide (6501) at a mass ratio o...

Embodiment 2

[0035] (1), the preparation of intermediate furfural extraction oil sulfonic acid

[0036] Add the furfural extracted oil into the four-necked bottle, start the stirring, raise the temperature to 45°C, and feed in SO with a concentration of 8%. 3 Mixed gas for sulfonation reaction, react for 1 hour, stop feeding SO 3 , keep the reaction temperature, aging for 1.5 hours, the intermediate product sulfonic acid is obtained.

[0037] (2), preparation of furfural extraction oil sulfonate

[0038] Control the temperature of the four-neck flask at 30°C, start stirring, slowly add NaOH solution with a concentration of 15% to the intermediate product, adjust the pH value to 8-9, continue stirring for 1 hour, and after removing water and drying, the product furfural is extracted Oil sulfonate.

[0039] (3), interfacial tension test

[0040] Oil displacement system: a system composed of furfural extracted oil sulfonate and coconut oil fatty acid diethanolamide (6501) at a mass ratio ...

Embodiment 3

[0050] (1), the preparation of intermediate furfural extraction oil sulfonic acid

[0051] Add the furfural extracted oil into the four-necked bottle, start the stirring, raise the temperature to 40°C, and feed in SO with a concentration of 10%. 3 Mixed gas for sulfonation reaction, react for 2 hours, stop feeding SO 3 , keep the reaction temperature, aging for 1 hour, the intermediate product sulfonic acid is obtained.

[0052] (2), preparation of furfural extraction oil sulfonate

[0053] Control the temperature of the four-necked flask at 35°C, turn on the stirring, slowly add NaOH solution with a concentration of 15% to the intermediate product, adjust the pH value to 8-9, continue stirring for 0.5 hours, and after dehydration and drying, the product furfural is extracted Oil sulfonate.

[0054] (3), interfacial tension test

[0055] Oil displacement system: a system composed of furfural extracted oil sulfonate and coconut oil fatty acid diethanolamide (6501) at a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com