Double-circular-disc socket-type ring lock scaffold

A scaffolding and socket-type technology, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve problems such as loose bolts and decreased self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

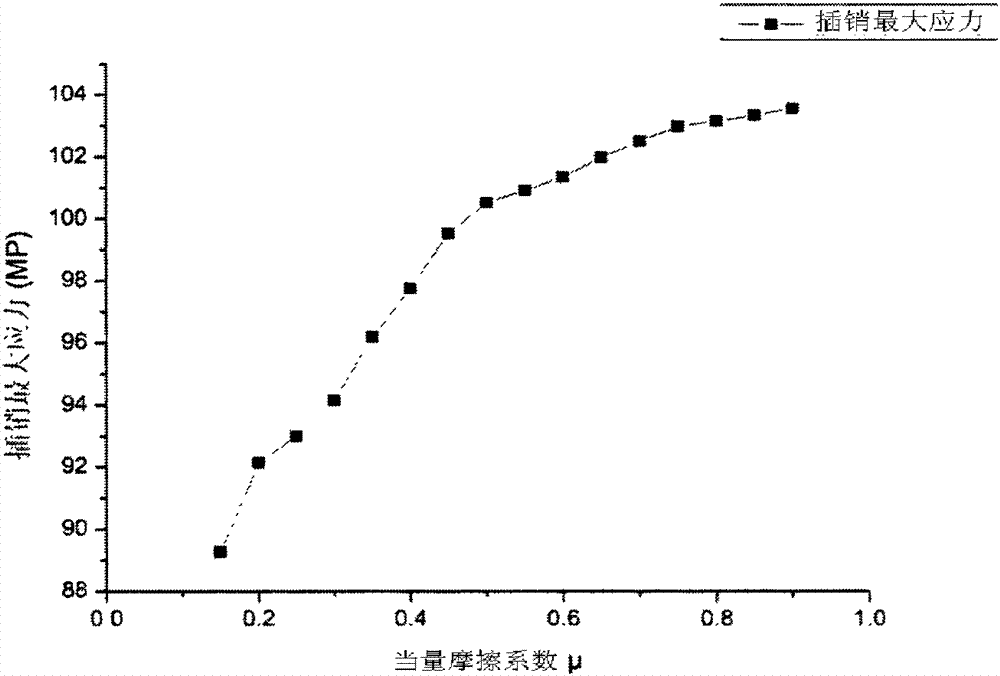

[0019] Through in-depth research on the bearing mechanism of scaffold nodes, the present invention finds out the most favorable structural form for node stability, optimizes the structure, and provides a high-stability double-disc buckle-type scaffold. The specific implementation is as follows:

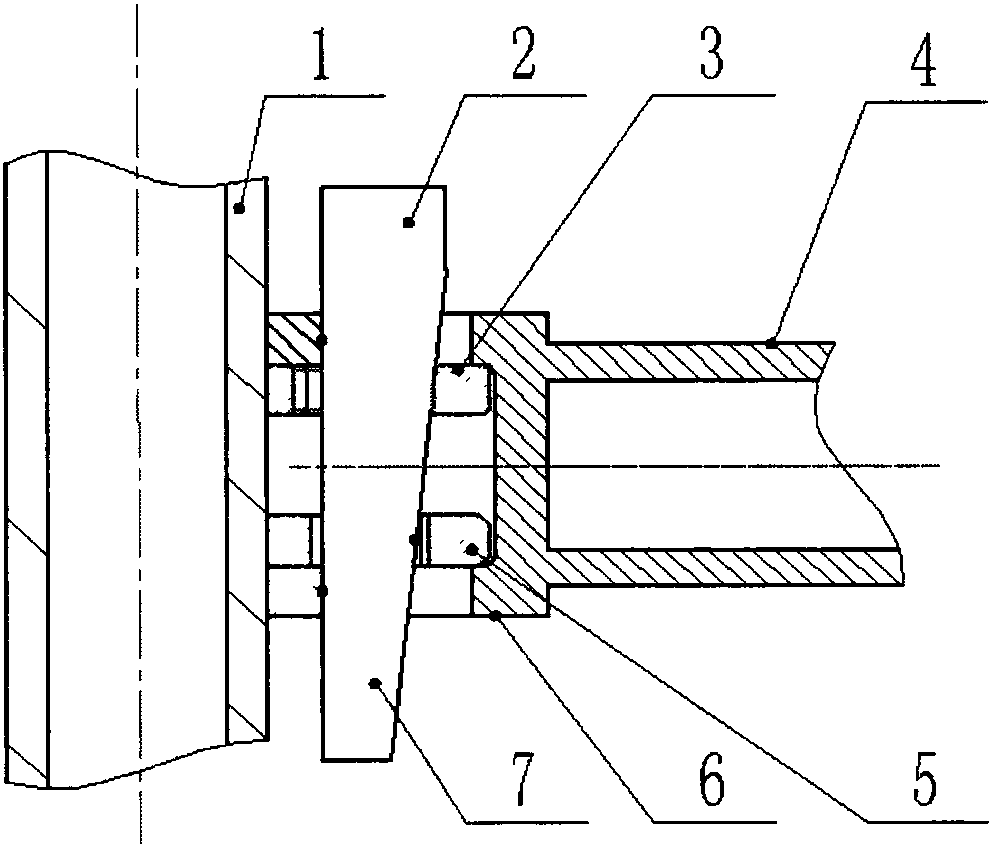

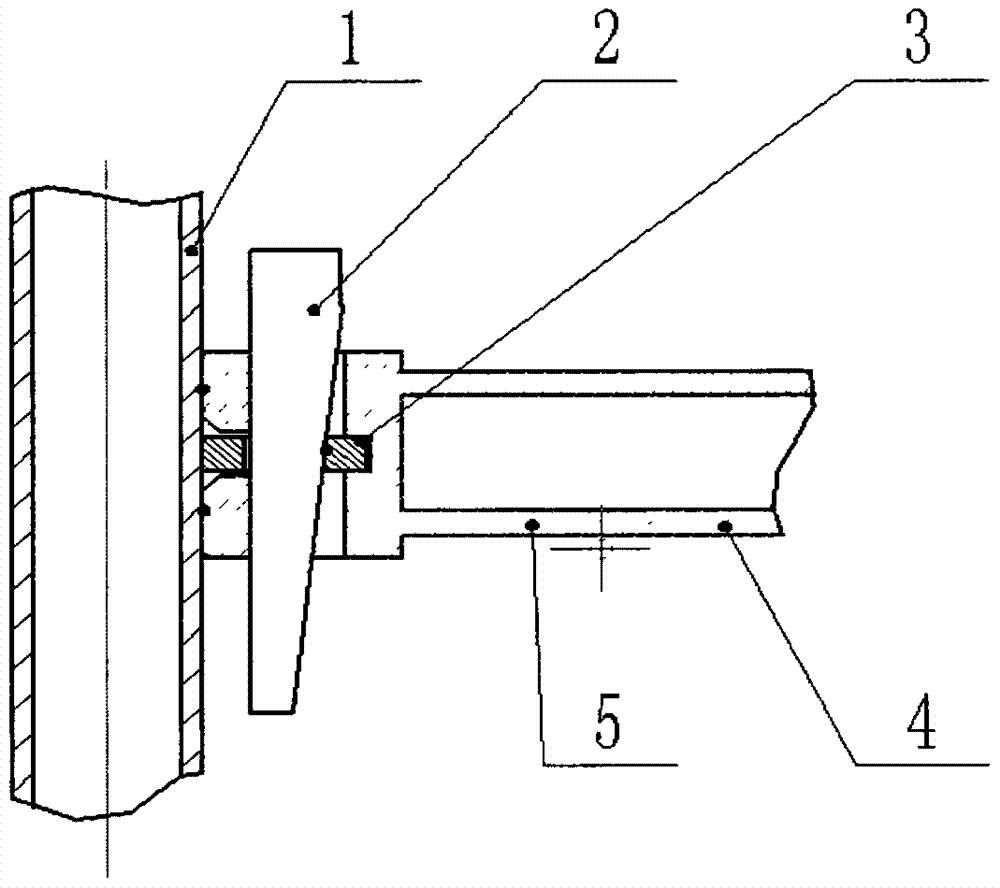

[0020] The scaffolding consists of a vertical pole, a horizontal pole, a socket plate, a wedge pin, a diagonal pole, a crossbar end buckle joint, and a diagonal pole end buckle joint. See figure 2 and image 3 . The materials and dimensions of the vertical poles and horizontal poles comply with the relevant provisions of the industry standard "Safety Technical Regulations for Socket-type Buckle-type Steel Pipe Supports for Building Construction" (JGJ 231-2010). The socket plate and the wedge pin are made of ordinary carbon steel plate, and the cross bar end buckle joint is made of ordinary carbon steel plate by bending on a bending machine. The double discs are welded on the pole....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com