Universal linear tower ground wire lifting device

A technology of ground wire lifting and straight tower, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems that are not conducive to field operations and high-altitude operations, cannot ensure the smooth completion of work, and consume a lot of physical strength for personnel, so as to achieve simplification of work and low weight. Lightweight, labor cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

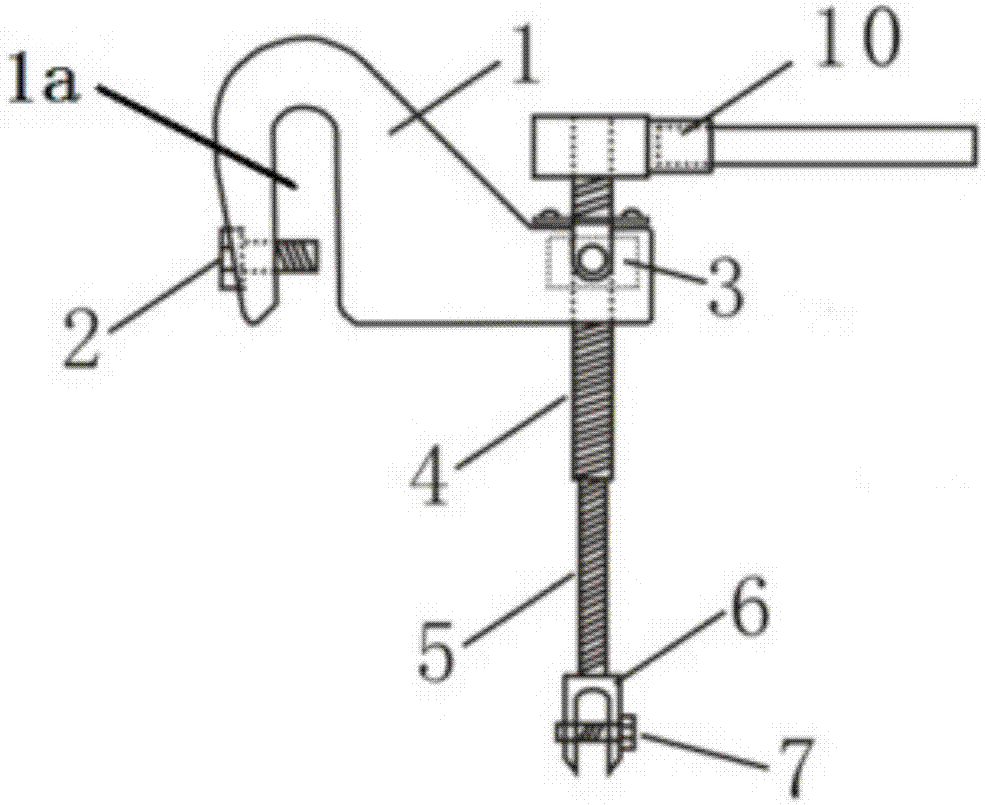

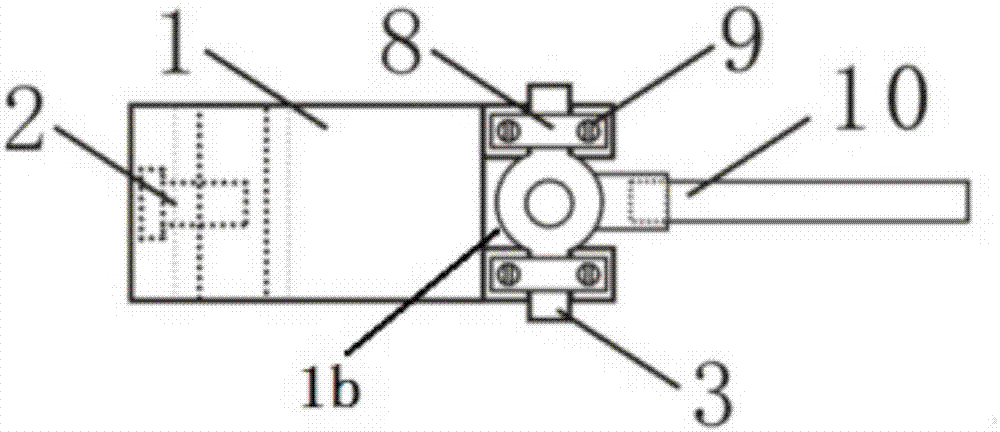

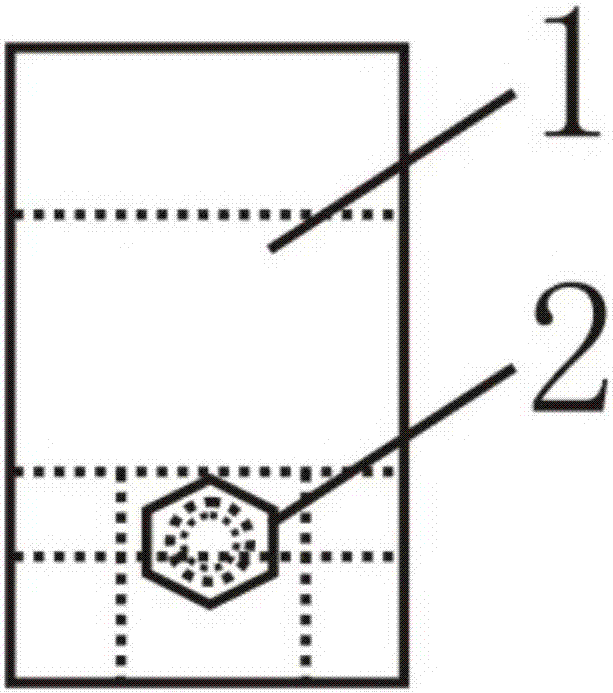

[0019] Such as figure 1 , figure 2 , image 3 As shown, the general-purpose linear tower ground wire lifting device of the present invention includes a lower tightening lead screw 5, a tubular upper tightening lead screw 4 with inner hole threads and outer threads that is fitted on the upper part of the lower tightening lead screw through thread fit, The load-bearing ten-piece set on the tightening thread lead screw through thread fit 3, the pressure plate pressed on the ten-piece and fixed by the slotted screw 9, and the load-bearing ten-piece two through the end lug plate The cantilever aluminum alloy base on the end joint 1, the operating handle 10 set on the upper end of the tightening thread screw, and the integral body for connecting the ground wire (or extending fittings) with the opening downwards at the lower end of the lower tightening thread screw Type U-shaped notch connector 6, a locking bolt 7 for locking the ground wire (or extending fittings) fitted on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com