Single line fire alarm line fixing clamp

A technology for fixing clamps and police lines, applied in electrical components and other directions, it can solve the problems of product failure, low material strength, unusability, etc., and achieve the effect of strong deformation resistance, good corrosion resistance and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

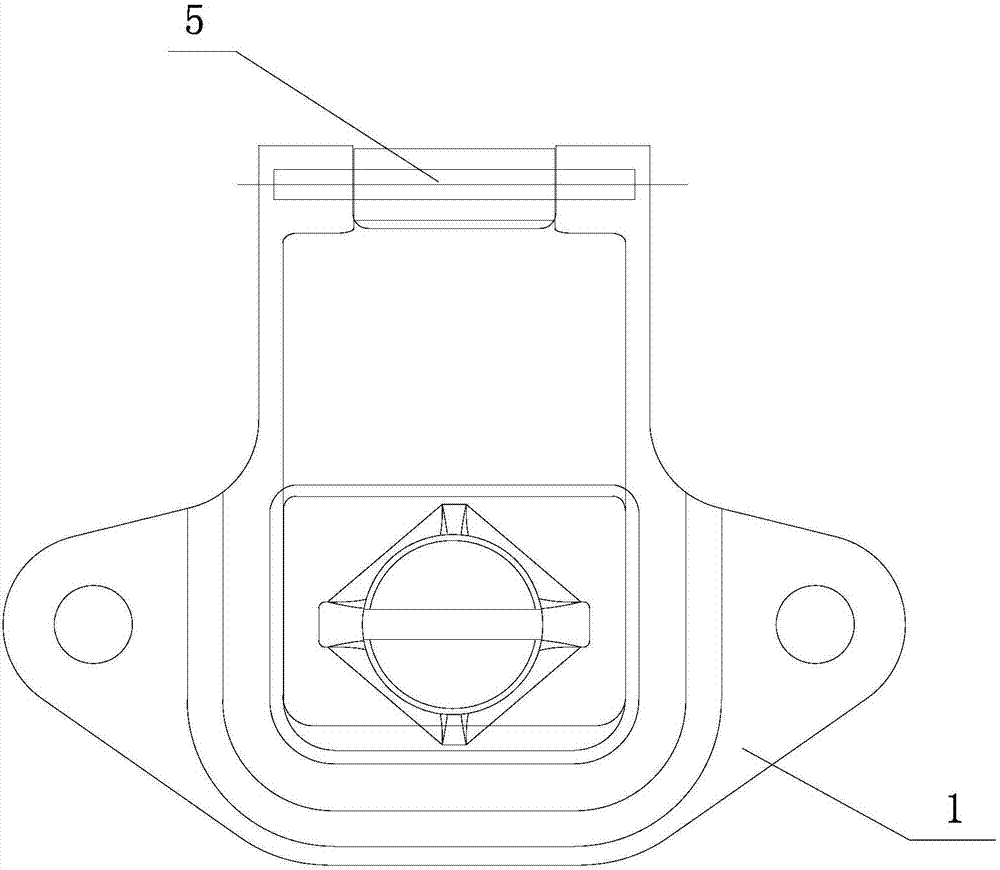

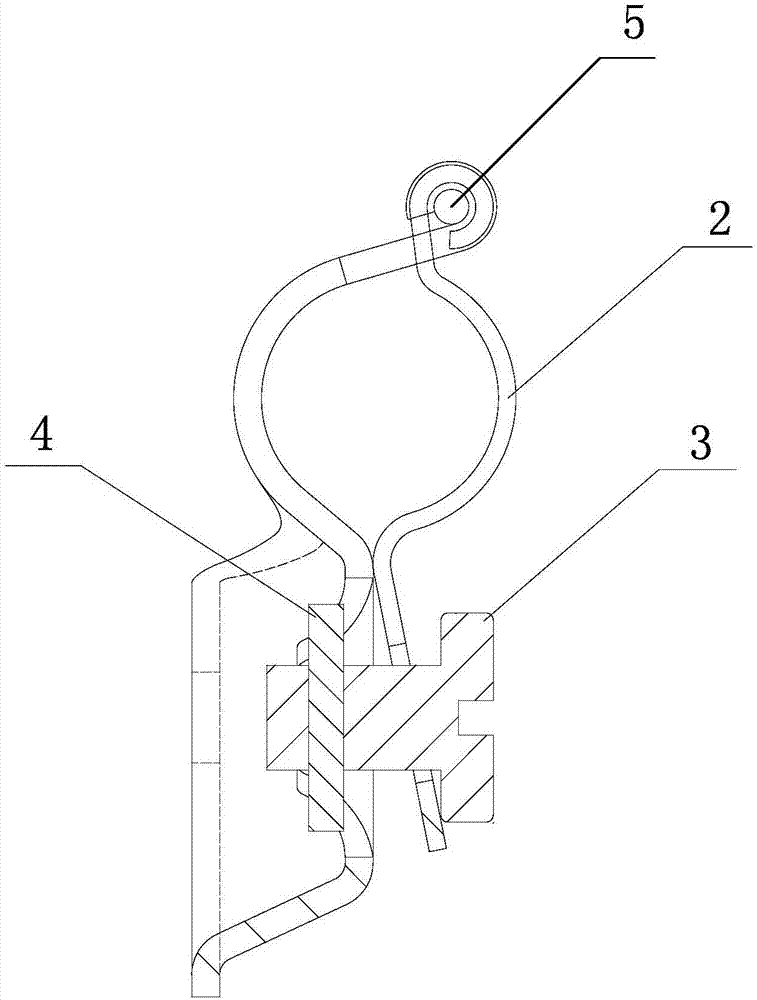

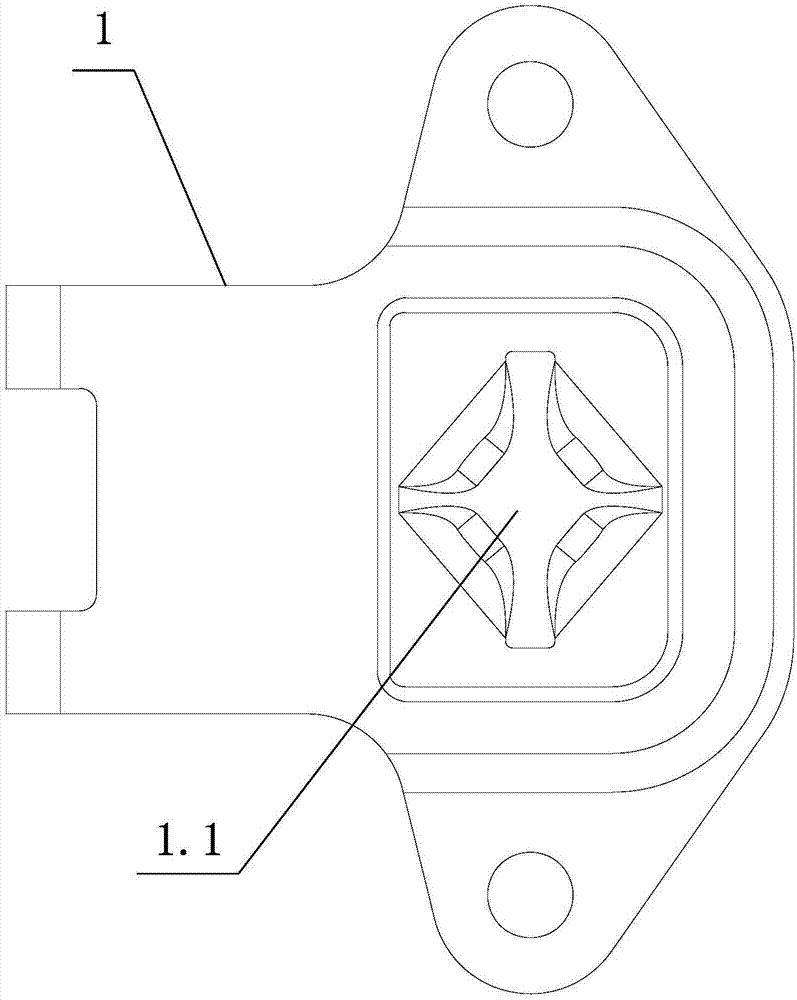

[0030] Such as figure 1 , figure 2 , image 3 with Figure 4 The single-wire fire alarm wire fixing clamp shown includes: a base 1, an upper pressing piece 2, a compression screw 3 and a compression screw pin 4;

[0031] The tail end of the base 1 is hinged to the tail end of the upper pressing piece 2 through the rotating shaft 5;

[0032] Wherein, the base 1 is provided with a downwardly concave arc-shaped part near the hinge part of the rotating shaft 5, and an upwardly protruding arc-shaped part is arranged above the corresponding position of the upper pressing piece 2 and the base 1, and the upper pressing piece 2 and the base 1 are flipped and fastened relative to each other. The arc-shaped part of the rear base 1 is fastened with the arc-shaped part of the upper pressing piece 2 to form a hole; the left and right sides of the base 1 are respectively provided with a base mounting hole;

[0033] The front end of the base 1 is processed with a cross hole 1.1;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com