Waste heat power generation grid-connection interlocking system

A technology of waste heat power generation and interlocking system, which is applied in the direction of single-grid parallel feeding arrangement, protection switch operation/release mechanism, etc. The effect of misoperation, ensuring safety, and preventing the isolated operation of the power generation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

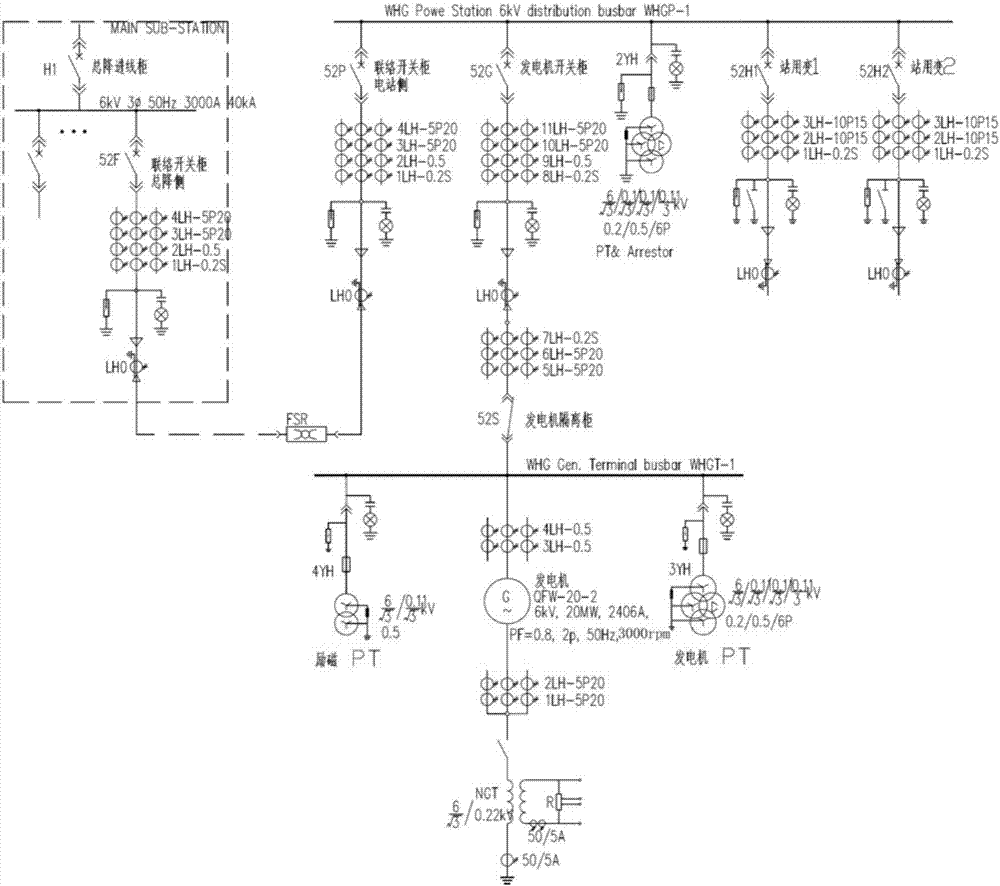

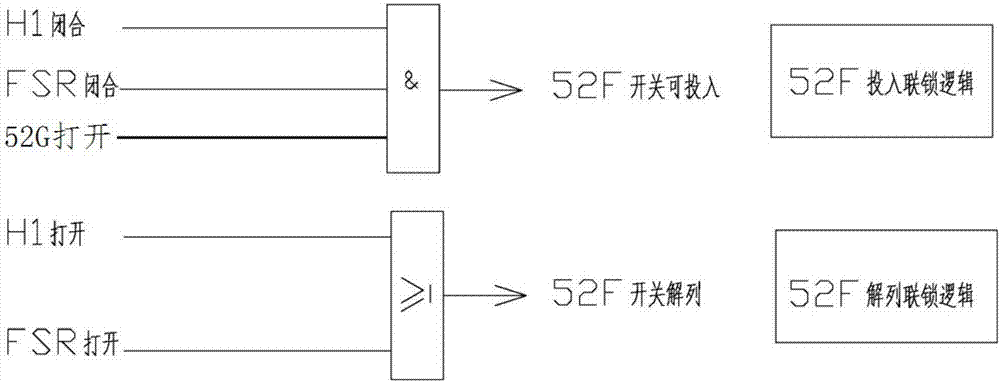

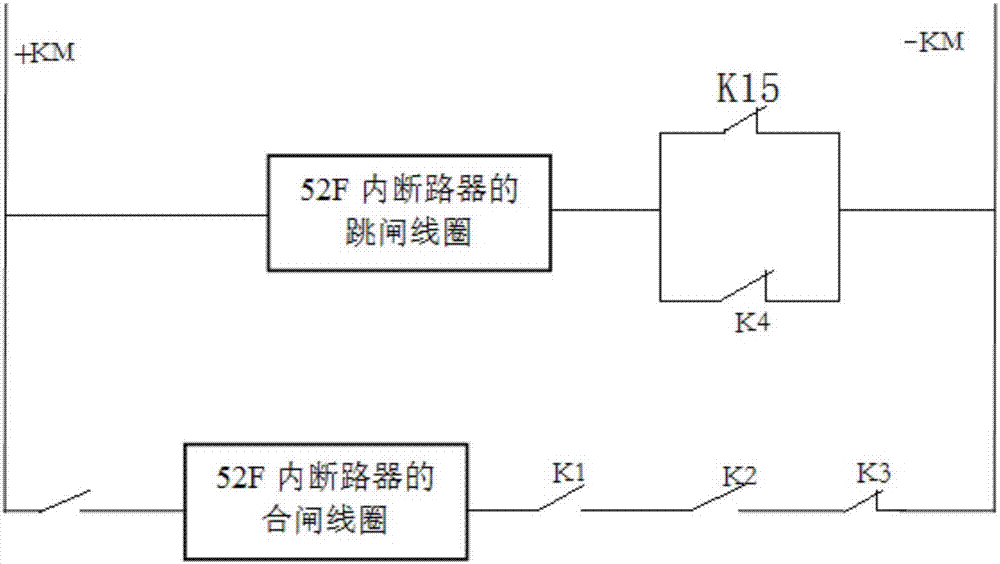

[0020] Such as figure 1 As shown, a waste heat power generation grid-connected interlocking system includes a waste heat power generation system, a total step-down station, and also includes a fast switch cabinet FSR, a power station side contact switch cabinet 52P, a generator switch cabinet 52G, a power distribution bus, and a waste heat power generation system Power generation is carried out through the waste heat in the cement production process; the total drop station includes the total drop bus, the total drop incoming line cabinet H1, the main drop side contact cabinet 52F, the main drop bus incoming cabinet H1 is connected to the main drop bus, and the total drop bus It is connected with the tie switchgear 52F on the main drop side, the tie switchgear 52F is connected with the fast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com