Self-propelled multi-row garlic combine harvester

A combine harvester and self-propelled technology, which is applied to digging harvesters, harvesters, topping machines, etc., can solve the problems of large excavation resistance, low degree of automation, and manual completion, so as to improve row spacing adaptability and reduce Impurities such as soil reduce excavation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

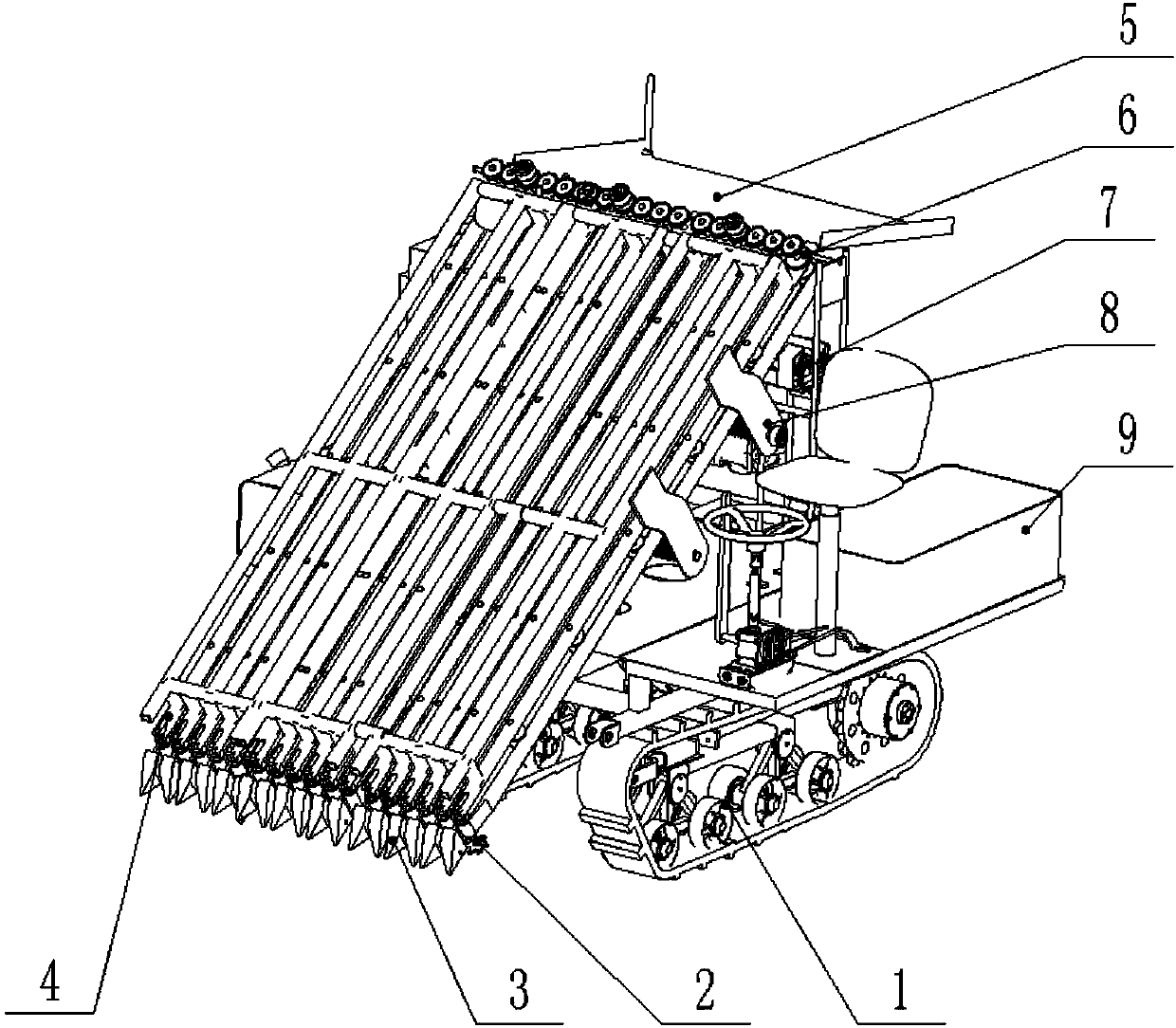

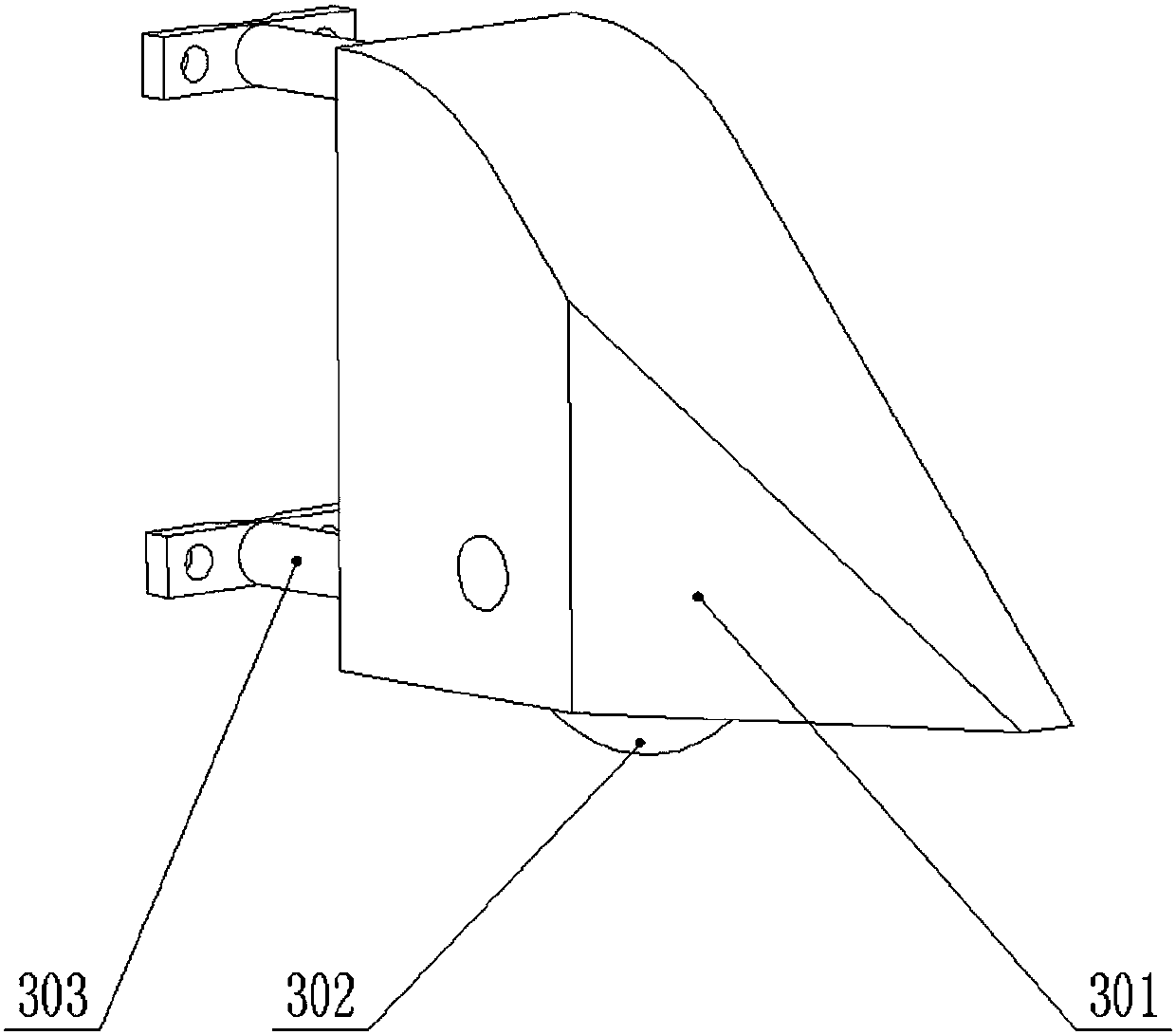

[0032] As shown in the drawings, the self-propelled multi-row garlic combine harvester includes a chassis 1, an engaging power digging disc 2, a depth-limiting and grain-holding mechanism 3, a clamping and conveying device 4, a seedling throwing device 5, and a seedling cutting mechanism 6. Root and hair excision device 7, remove soil alignment mechanism 8, garlic collection box 9.

[0033] The chassis 1 adopts a pure hydraulic crawler chassis, and the power transmission is composed of a closed hydraulic system composed of a double variable pump and a double hydraulic motor. Simple structure and flexible operation.

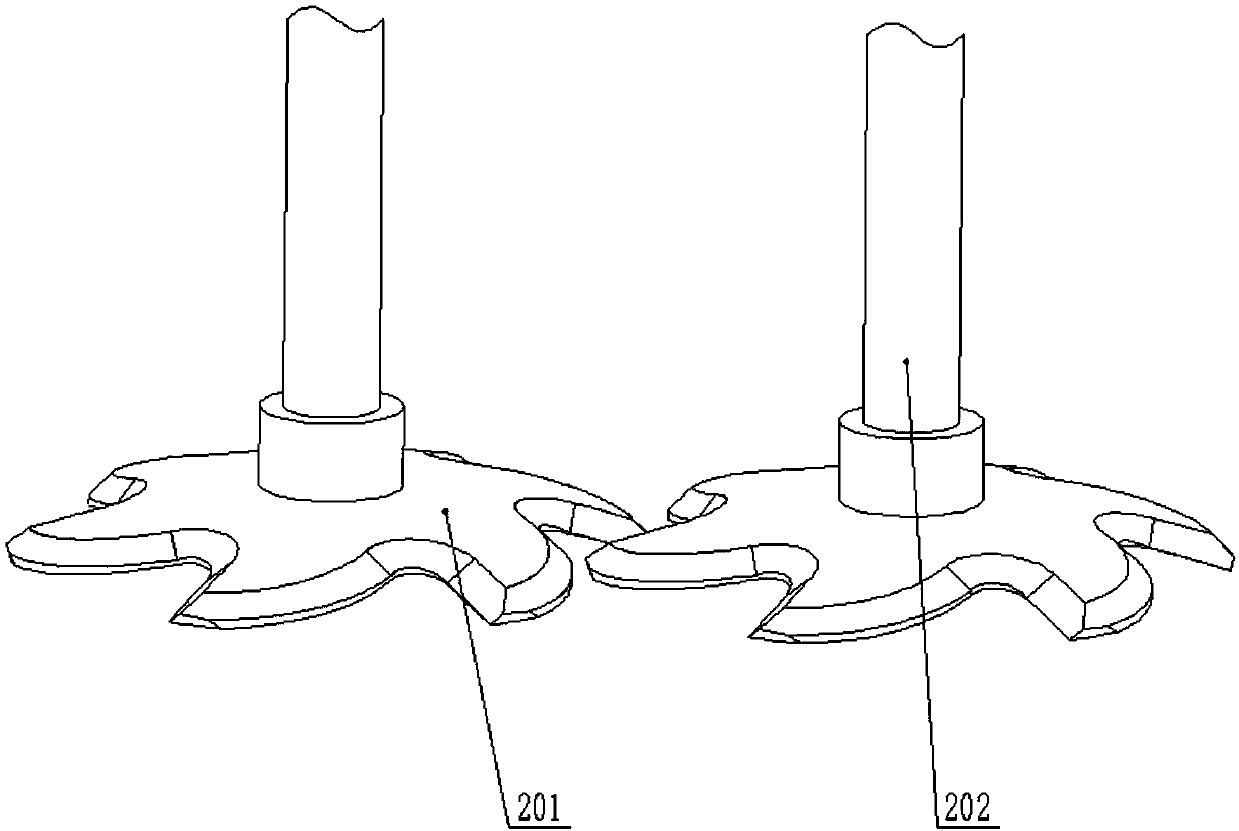

[0034] The meshing power digging disc mechanism 2 includes a power disc 201 and a power disc mounting shaft 202 . Each row of excavating mechanism is composed of two power discs 201 meshing with each other, and the power discs 201 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com