Manufacture method and device of vacuum low-temperature baked yellow peach powder

A vacuum low temperature, production method technology, applied in application, food processing, food science and other directions, can solve the problems of single variety of traditional food, insufficient attention to traditional food, insufficient processing methods, etc., to achieve simple and convenient operation, no sticky and no taste. , mature and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A low-vacuum low-temperature baked yellow peach powder and a production method thereof, comprising the following steps: removing impurities from freshly harvested yellow peaches, drying them in the air, and then baking them in a special baking oven. The baking is carried out at a low temperature. It should be controlled below 150 degrees Celsius, and ensure that the yellow peaches can be roasted and then made into powder for later use.

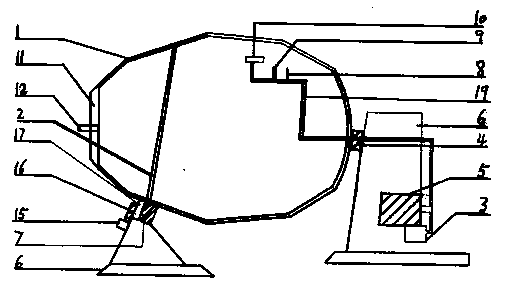

[0024] The present invention is realized through the following technical scheme: its main components include: equipment support, vacuum tank, electrical control panel, vacuum pump facility, transmission system equipment, and cover.

[0025] The vacuum tank of the rotary stirring low-temperature baking equipment is supported by two equipment supports, and the vacuum tank can rotate; the equipment support is equipped with electrical control panels, vacuum pump facilities, supporting rollers, motors, gearboxes, and moving wheels.

[0026] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com