Stepping type pellet roasting equipment

A step-by-step and roasting technology, applied in the field of pellet roasting, can solve the problems of increased energy consumption, many wearing parts of high temperature-resistant alloy steel, poor sealing effect, etc., and achieves a reduction in the number of trolleys, a simple equipment structure, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

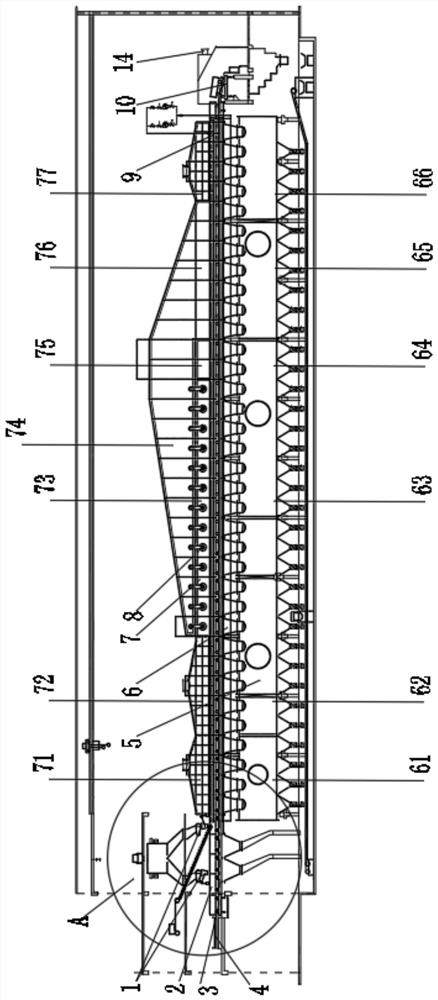

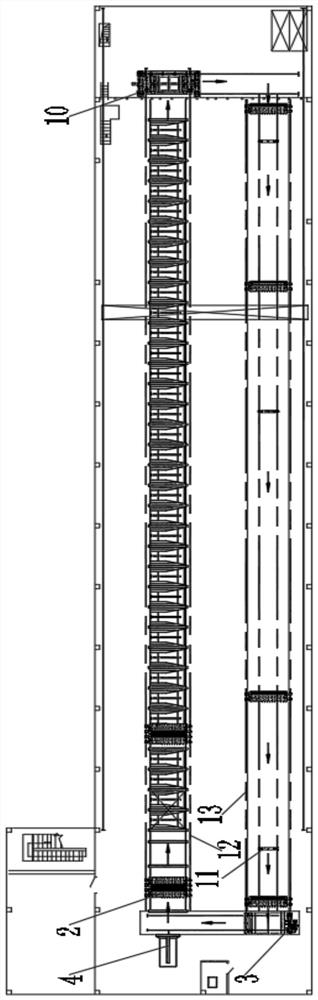

[0040] see Figure 1-4 , a step-by-step pellet roasting equipment, comprising a bottom laying device 1, a trolley 2, a bellows 6, a roasting furnace cover 7, a sealing device 9, and a track 15;

[0041] The track 15 is used to provide a route for the trolley 2 to travel;

[0042] The trolley 2 is slidably connected to the track 15, and is used to place pellet raw materials;

[0043] Bottom paving device 1 is fixedly connected to the top of the trolley 2. In order to ensure the uniformity of pellet roasting and protect the main beam, end beam and baffle of the trolley 2 from high temperature damage, a layer is laid on the trolley 2. cooked ball;

[0044] Roasting furnace cover 7 is used to realize the roasting of pellet raw material in trolley 2, and said roasting furnace cover 7 is located above trolley 15;

[0045] The bellows 6 is fixedly connected to the outside of the bottom end of the roasting furnace cover 7, the bellows 6 is located below the trolley 2, and the bellows...

Embodiment 2

[0090] see figure 1 , in order to realize the roasting and molding processing of green pellets, the roasting furnace cover 7 includes a blast drying section, a draft drying section, a preheating section, a roasting section, a soaking section and a cooling section, thereby completing the green pellets in the trolley. Roasting and molding processing of dough.

[0091] The cooling section is further divided into a cooling section I and a cooling section II;

[0092] The roasting furnace cover 7 is located at the top of the trolley 2, and the bellows 6 is located at the bottom of the trolley 2. The roasting furnace cover 7 and the bellows 6 are parallel up and down, and the bellows 6 communicates with the roasting furnace cover 7, so that the wind box 6 The gas can pass through the green pellets in the trolley 2 to enter the roaster cover 7 .

[0093] The roasting furnace cover 7 is divided into blast drying cover 71, exhaust drying cover 72, combustion chamber 73, preheating ro...

Embodiment 3

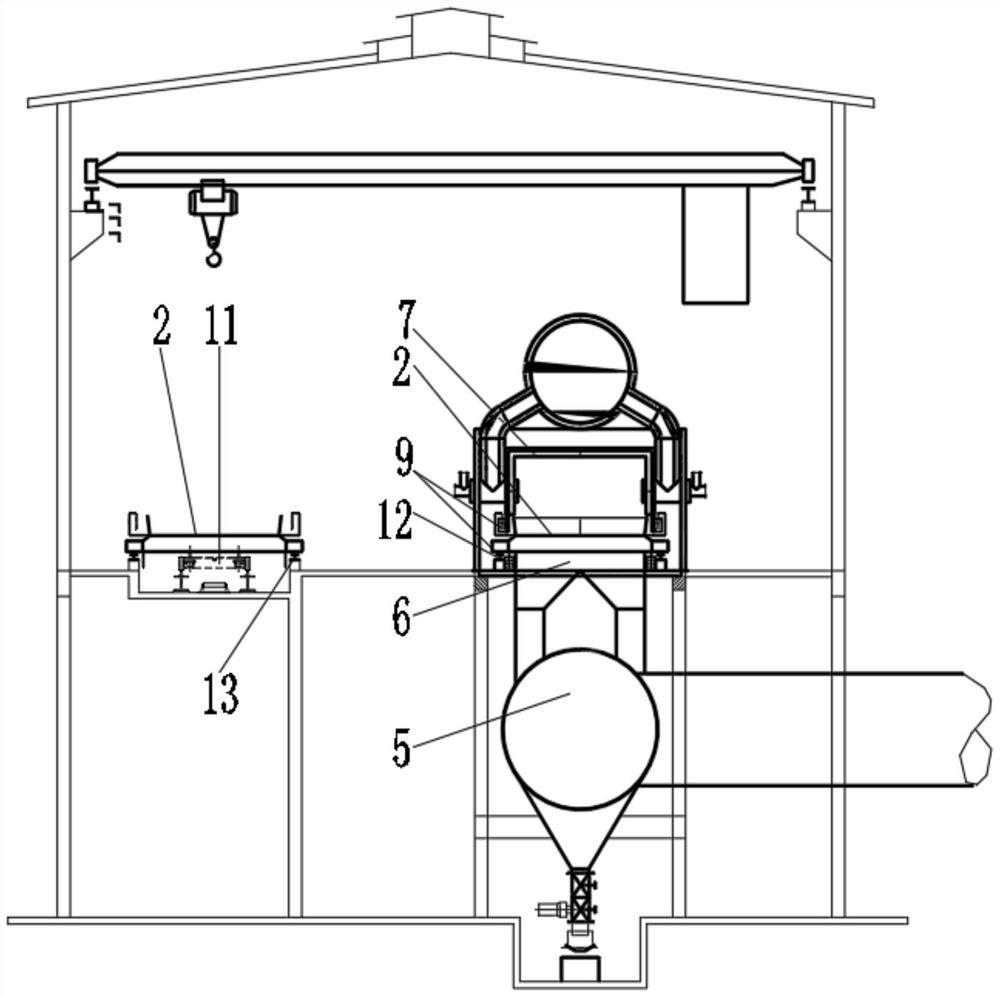

[0110] see image 3 Since the trolley 2 enters between the bellows 6 and the roasting furnace cover 7, there will inevitably be gaps between the trolley 2 and the bellows 6, and between the trolley 2 and the roasting furnace cover 7, which are not tightly fitted. Sealing device 9 is designed for the airtightness between trolley 2 and bellows 6, and between trolley 2 and roaster cover 7, effectively avoiding air leakage between trolley 2 and bellows 6, and between trolley 2 and roaster cover 7 .

[0111] Described roasting furnace cover 7 side, between bellows 6 and trolley 2, between roasting furnace cover 7 and trolley 2 are provided with sealing device 9, described sealing device 9 selects water sealing device for use, can effectively block air leakage; Advanced mechanical seals are adopted between the first bellows 6 and the last bellows 6 at the left and right ends of the roasting furnace cover 7 and the trolley 2; The joint sealing of the windshield and micro-negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com