Resin molding apparatus and method for manufacturing resin molded product

A technology of resin molding and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as positional deviation of resin molded products, and achieve the effect of reducing molding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0086] (Structure of resin molding device)

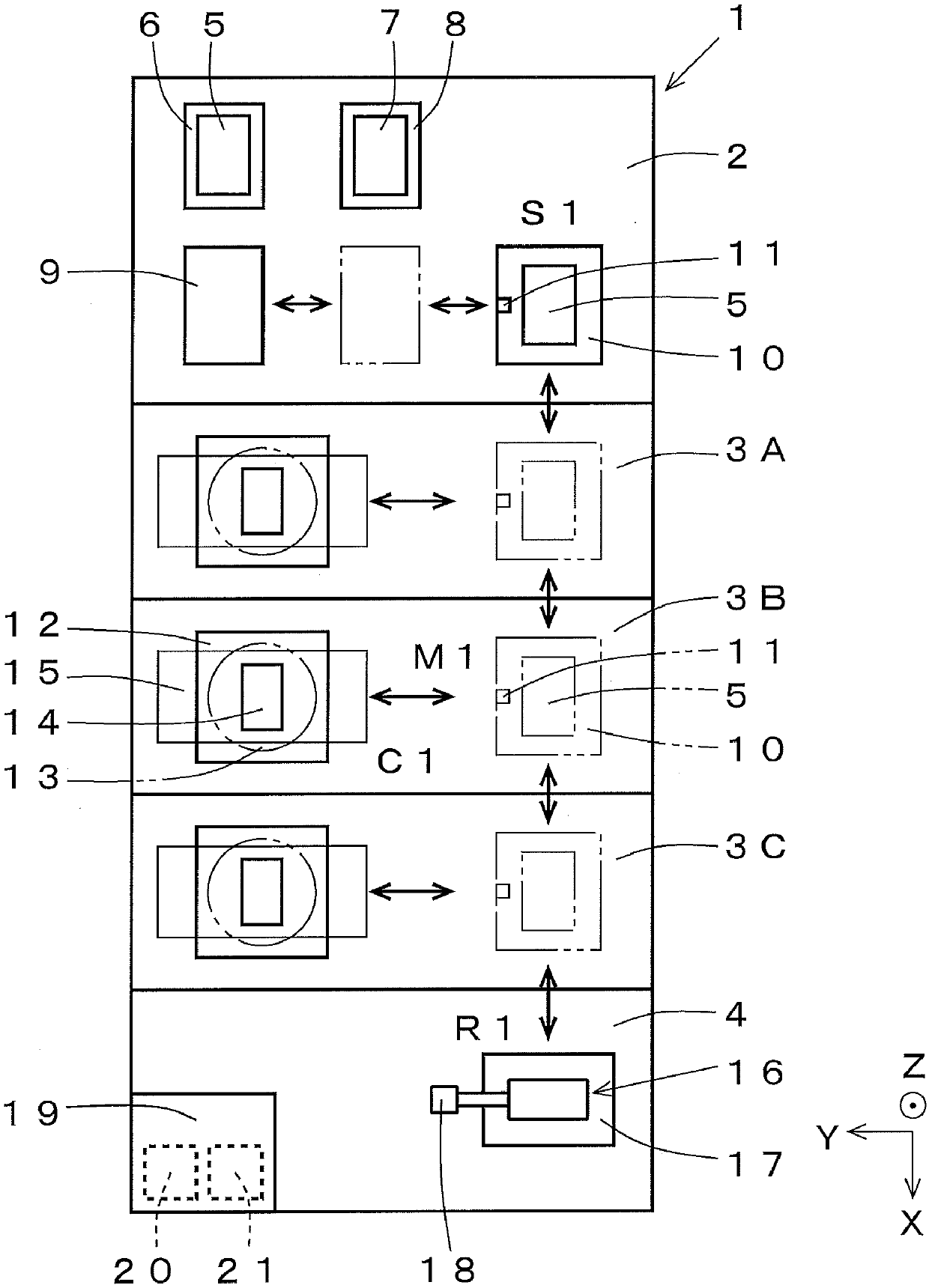

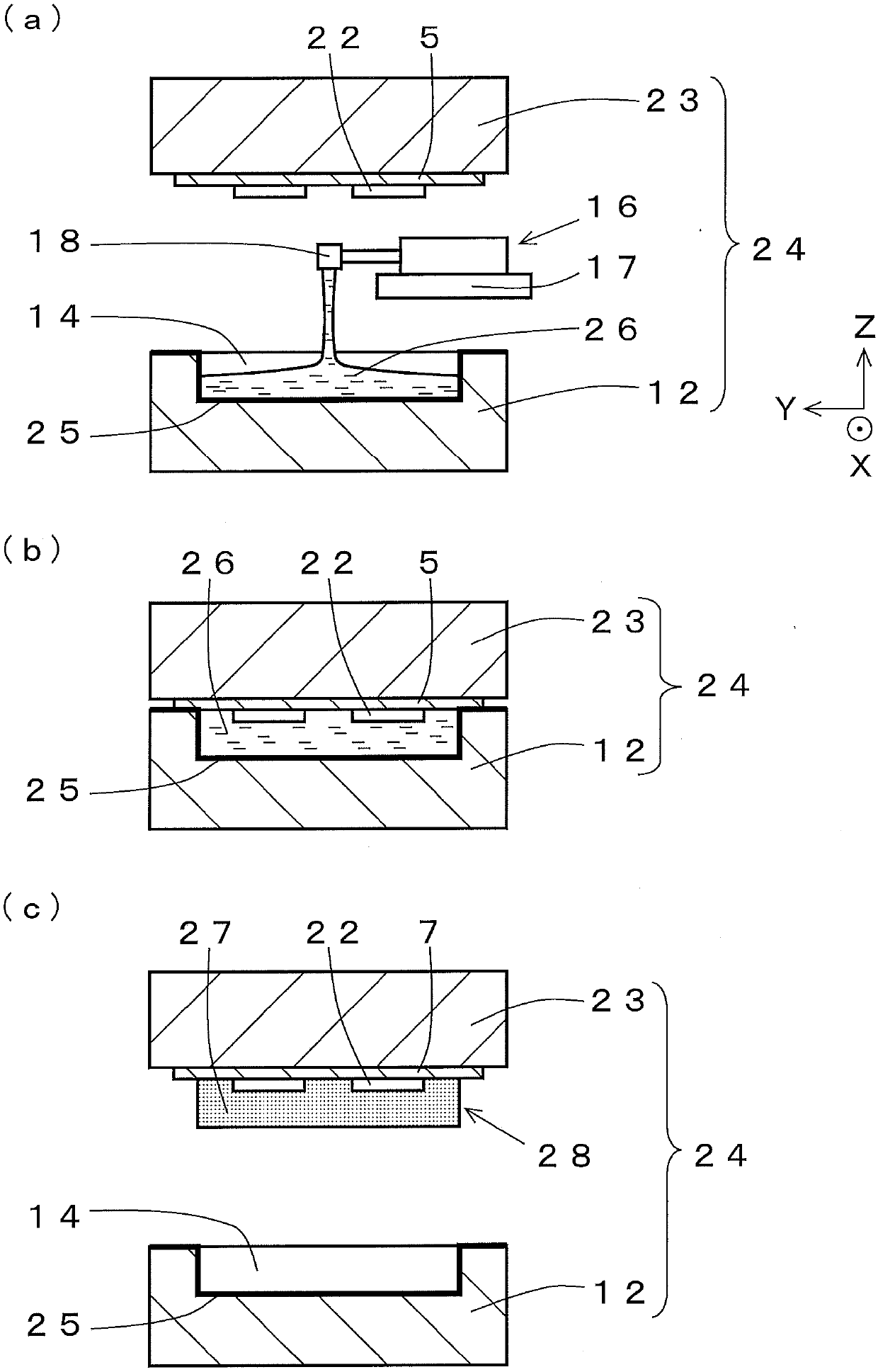

[0087] refer to figure 1 , the configuration of the resin molding apparatus according to Embodiment 1 of the present invention will be described. figure 1 The shown resin molding apparatus 1 is, for example, a resin molding apparatus using a compression molding method. An example of using a fluid resin, that is, a liquid resin, as the resin material is shown.

[0088] The resin molding apparatus 1 includes a substrate supply and storage module 2, three molding modules 3A, 3B, and 3C, and a resin supply module 4 as constituent elements. The substrate supply and storage module 2, the molding modules 3A, 3B, and 3C, and the resin supply module 4, which are structural elements, are mutually detachable and replaceable with respect to other structural elements.

[0089] The substrate supply and storage module 2 is provided with: a pre-encapsulation substrate supply part 6, which supplies the pre-encapsulation substrate 5; a post-enca...

Embodiment approach 2

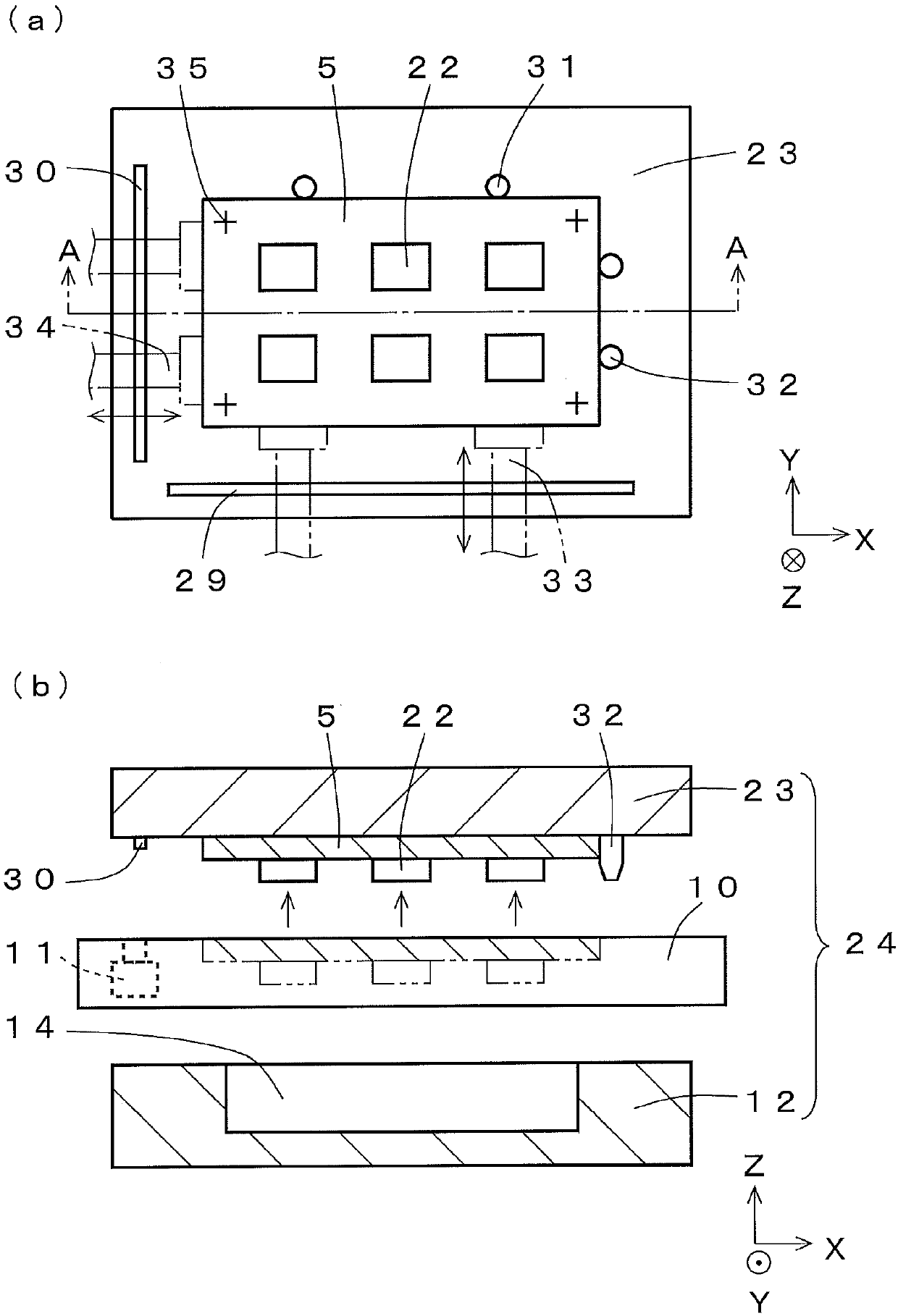

[0175] refer to Figure 8 ~ Figure 9 , the operation of verifying whether or not the pre-package substrate 5 supplied to the upper mold 23 is normally positioned in Embodiment 2 will be described. The difference from Embodiment 1 is that the positioning is verified by photographing two positions at the ends of the pre-packaging substrate 5 along the X direction and the Y direction. Accordingly, not only the X direction and the Y direction but also the θ direction can be verified to verify whether the positioning is performed normally. The other operations (manufacturing method) and the configuration of the molding die are the same as those in Embodiment 1, and thus description thereof will be omitted.

[0176] (Position verification operation of substrate (part of manufacturing method of resin molded product))

[0177] Next, the operation of verifying whether or not the pre-packaging substrate 5 is normally positioned in Embodiment 2 will be described. The description here ...

Embodiment approach 3

[0202] refer to Figure 10 , the operation of verifying whether or not the pre-package substrate 5 supplied to the upper mold 23 is normally positioned in Embodiment 3 will be described. The description here is also a description of a part of the manufacturing method of the resin molded article. The difference from Embodiment 1 is that the upper mold 23 is provided with a U-shaped reference mark including the X direction and the Y direction, and the position of the corner of the substrate is used for data processing. The configuration and operation (manufacturing method) of the other molding dies are the same as those in Embodiment 1, and thus description thereof will be omitted.

[0203] Next, the operation of verifying whether or not the pre-packaging substrate 5 is normally positioned in Embodiment 3 will be described. Such as Figure 10 As shown in (a), a U-shaped reference mark 36 is provided on the mold surface of the upper mold 23 . In this embodiment, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com