Coking wastewater electrolysis unit with backwash function

A coking wastewater and electrolysis device technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve long-term impact, carcinogenic, toxic and harmful problems, and achieve waste and pollution reduction, Extended service life and environmentally friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

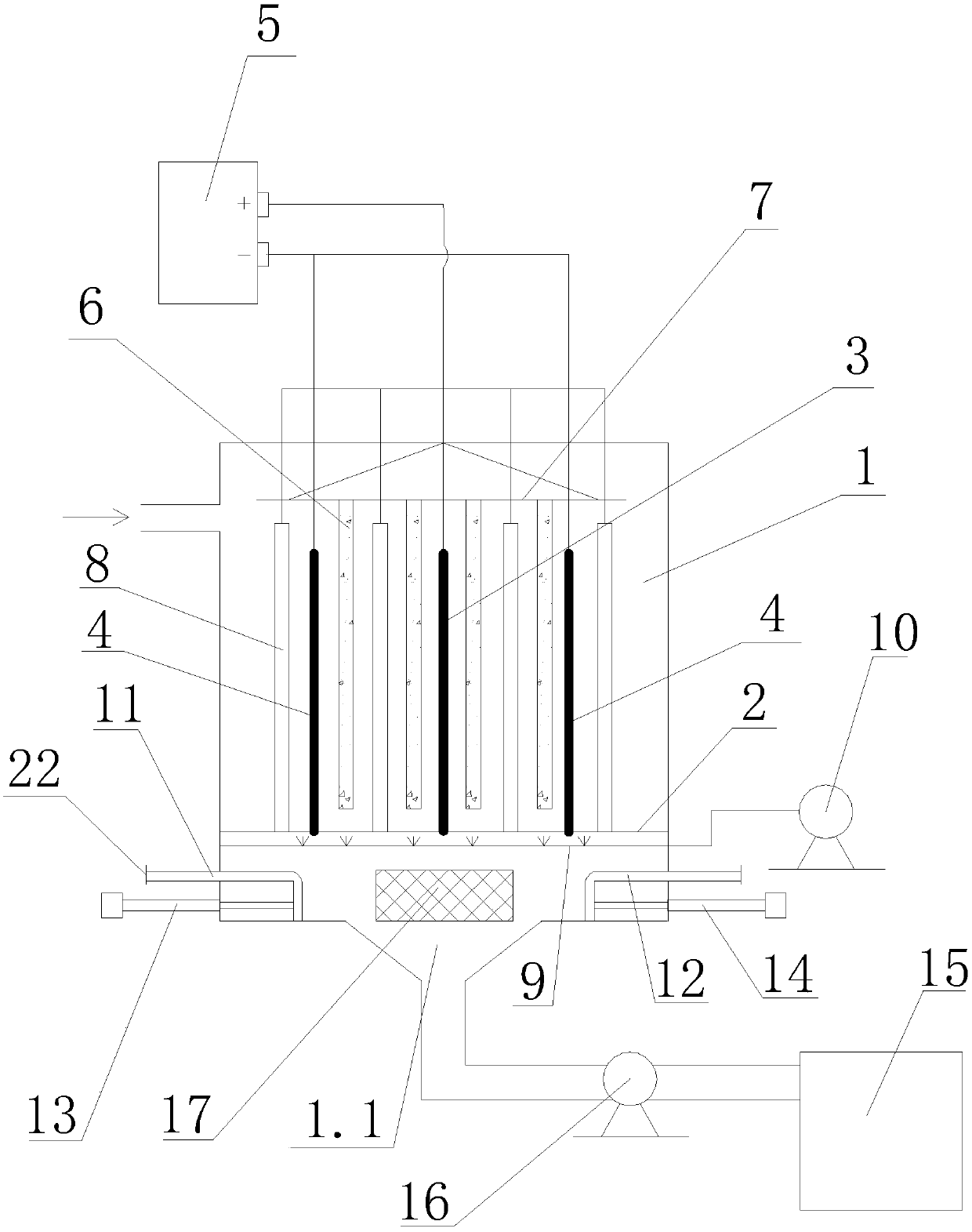

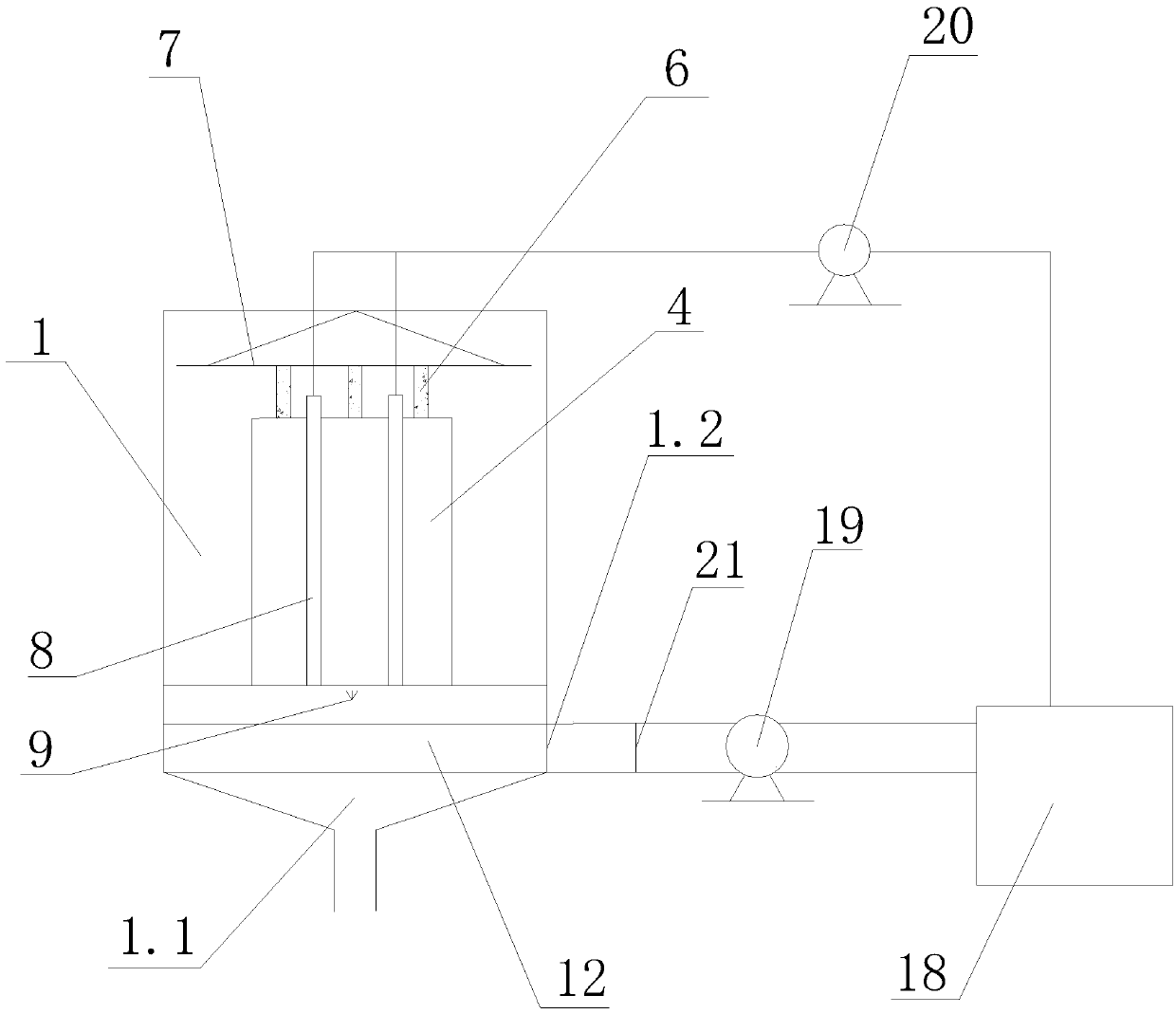

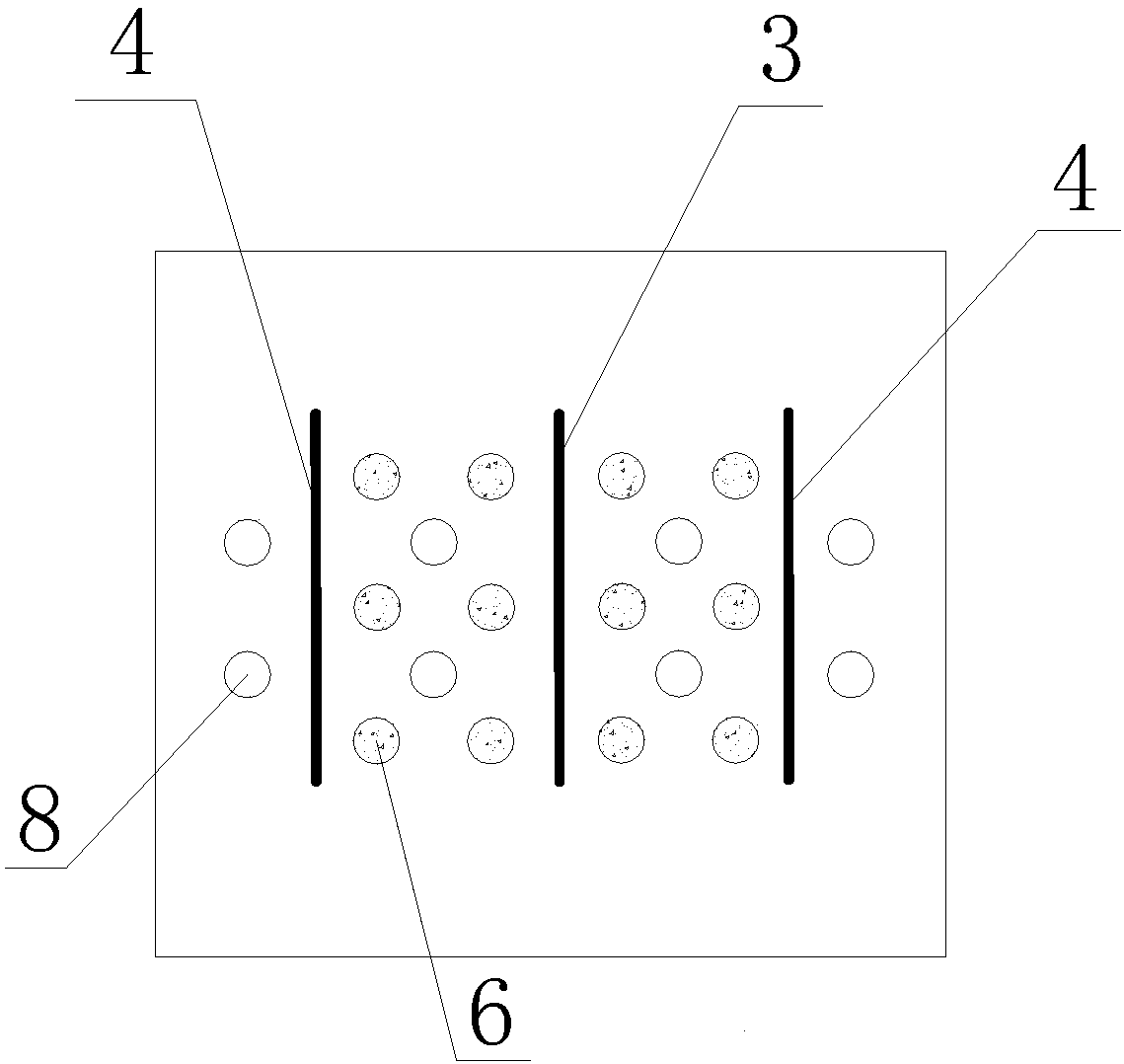

[0017] Such as Figure 1-4 As shown, a coking wastewater electrolysis device with backwashing function includes a tank body 1, a support frame 2 fixedly connected with the tank body 1 is arranged inside the tank body 1, and an anode is vertically arranged on the support frame 2 plate 3 and two cathode plates 4, the anode plate 3 is arranged between the two cathode plates 4, the anode plate 3 and the cathode plate 4 are connected to an external power supply 5, and the anode plate 3 and the cathode plate 4 are arranged There are a plurality of carrier rods 6 filled with composite catalysts, the plurality of carrier rods 6 are hung on the top of the tank body 1 through a hanging plate 7, the distance from the lower end of the carrier rods 6 to the support frame 2 is greater than zero, and the support frame 2 is also provided with multiple water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com