Cleaning device for spinneret plate machining

A technology of cleaning device and spinneret, applied in spinneret assembly, textile and papermaking, etc., can solve the problems of low cleaning efficiency, high cleaning cost, waste of resources, etc., and achieve the effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

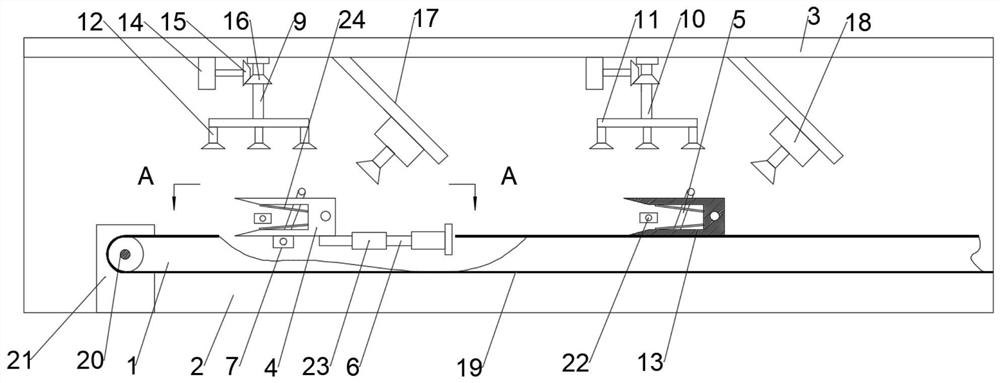

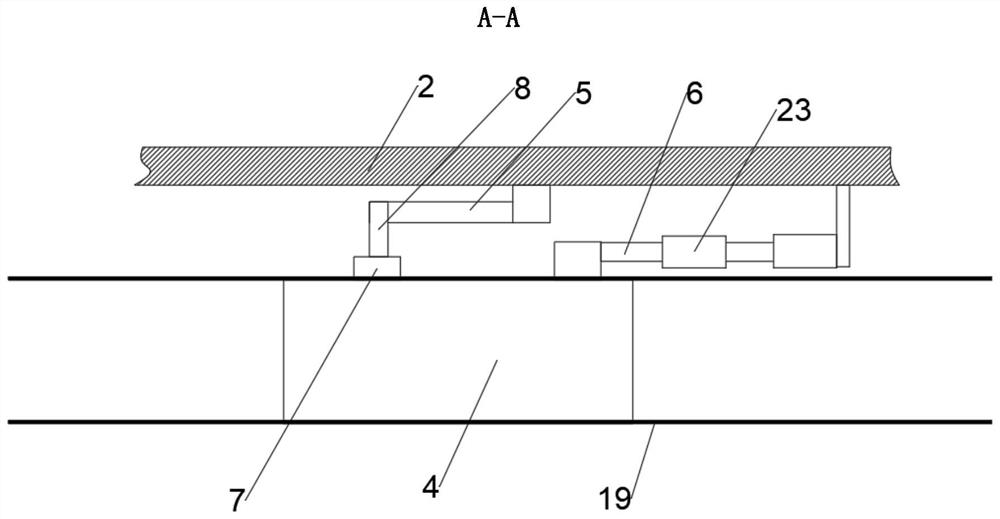

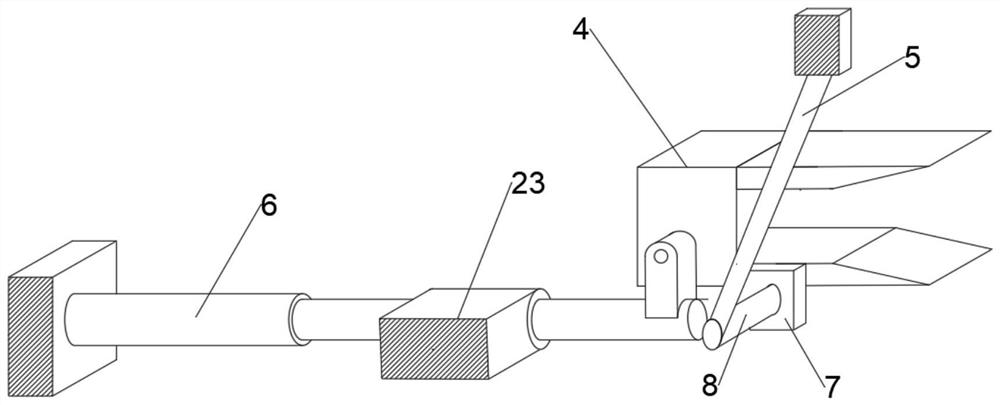

[0023] see Figure 1~4 , in an embodiment of the present invention, a cleaning device for spinneret processing, including a conveying device 1, a side wall 2, and a top wall 3, the side wall 2 is arranged on one side of the conveying device 1, and the top wall 3 is arranged on the Above the conveying device 1 and the top wall 3 is fixedly connected with the side wall 2. Two clamping and turning mechanisms 13 are fixed on the side wall 2. The clamping and turning mechanisms 13 include a clamp 4, a connecting rod 5, a hydraulic lifting and shrinking rod 6. Rotating base 7, rotating rod 8, guide rail 23, one side of the fixture 4 is fixedly connected with the rotating base 7, one end of the rotating rod 8 is rotationally connected with the rotating base 7 and the other end of the rotating rod 8 is rotationally connected with the connecting rod 5 , the connecting rod 5 is hinged on the side wall 2, one end of the hydraulic lift-contraction rod 6 is fixedly connected to the side wa...

Embodiment 2

[0030] see Figure 1~4 The difference between the embodiment of the present invention and embodiment 1 is that the two cleaning mechanisms 9 are provided with a rotating shaft 10, a rotating disk 11, and a nozzle 12, and the rotating shaft 10 is connected to the lower end surface of the top wall 3 in rotation and the rotating shaft 10 The lower end surface is fixedly connected with the turntable 11, and each cleaning mechanism 9 is provided with three nozzles 12 and the three nozzles 12 in each cleaning mechanism 9 are arranged at equal intervals along the circumference of the lower end surface of the turntable 11, and the lower end surfaces of the top wall 3 are respectively Two rotating motors 14 are fixedly connected, and the output shafts of the two rotating motors 14 are fixedly connected with a bevel gear I15, and the rotating shafts 10 in the two cleaning mechanisms 9 are provided with bevel gear II16 and bevel gear I15. Mesh transmission with bevel gear II16.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com