Defoaming device

A technology of defoaming device and spraying device, which is applied in the direction of biochemical cleaning device, enzymology/microbiology device, biochemical instrument, etc., which can solve the problem of untimely extrusion defoaming and defoaming, microbial damage of fermentation, and unsatisfactory effect and other problems, to achieve the effect of wide application range and no high-energy impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

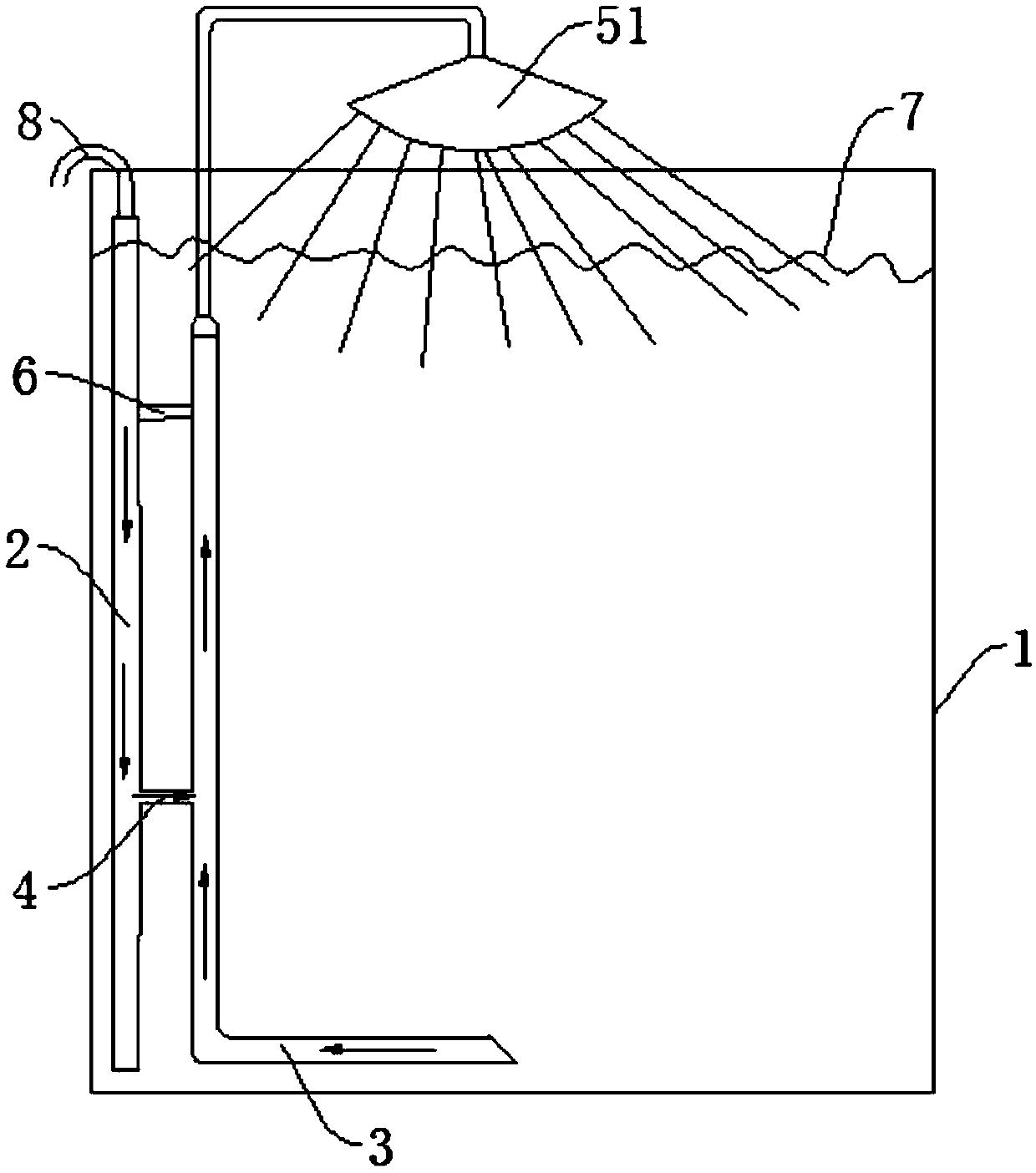

[0026] Referring to the accompanying drawings, in one embodiment of the present invention: a defoaming device, comprising: a reactor body 1, an air inlet pipe 2, a spray pipe 3 and a vent pipe 4; the air inlet pipe 2 is fixedly connected by means of a quick joint or the like On the inner wall of the reactor body 1, one end of the inlet pipe 2 is connected to an air compressor through a hose 8, and the use of compressed air to lift the liquid has more impact and can effectively ensure the defoaming effect. One end of the spray pipe 3 is arranged on the liquid surface 7 in the reactor body 1, the other end of the spray pipe 3 is arranged under the liquid surface 7 in the reactor body 1, and is arranged under the liquid surface 7 in the reactor body 1. One end of the spray pipe 3 is arranged in a trumpet shape, and the height of the liquid level 7 in the spray pipe 3 is consistent with the height of the liquid level 7 in the reactor body 1 under the action of the atmosphere. One ...

Embodiment 2

[0028] Referring to the accompanying drawings, in another embodiment of the present invention: the rest is the same as the first embodiment, the difference is that the shower device is a shower head 51, and the shower head 51 can be a common universal shower head 51. The beneficial effect of adopting the above technical solution is: the foam is broken by the liquid sprayed from the spray head 51 , the action area is large, and the efficiency is high.

Embodiment 3

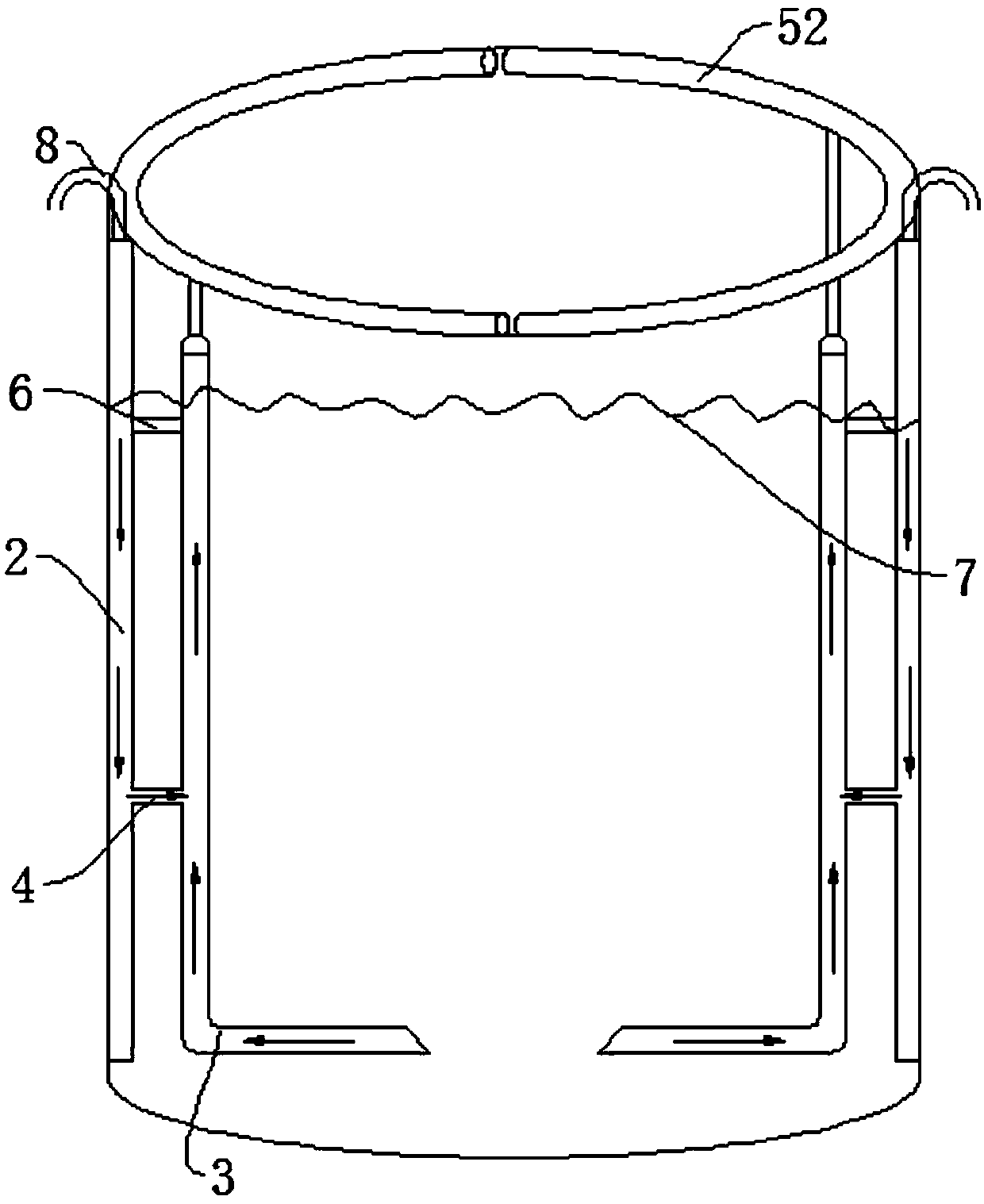

[0030] Referring to the accompanying drawings, in another embodiment of the present invention: the rest are the same as in Embodiment 2, the difference is that the shower device is an arc tube 52, and the arc tube 52 communicates with the spray tube, and the arc tube 52 Close to the inner wall of the reactor body. The lower half of the arc-shaped tube 52 is provided with several fine spray holes. When the liquid enters the arc-shaped tube 52, the liquid sprays out from the spray holes to crush the foam in all directions. The beneficial effect of adopting the above technical solution is: the arc tube 52 is close to the inner wall of the reactor body, preventing the reaction liquid in the reactor body from splashing on the inner wall of the reactor, and the reactants will adhere to the inner wall of the reactor, affecting the reaction effect .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com