Alloy baking system for steelmaking converter

A technology for steelmaking converters and alloys, which is applied in the field of alloy baking systems and online alloy baking systems for steelmaking converters. It can solve problems such as energy loss and temperature drop, and achieve reduced heat loss, reasonable process, and low difficulty in transformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that the following preferred embodiments should not be regarded as limiting the present invention, and the protection scope of the present invention should be determined by the scope defined in the claims. For those skilled in the art, without departing from the spirit and scope of the present invention, some improvements and modifications can also be made, and these improvements and modifications should also be regarded as the protection scope of the present invention.

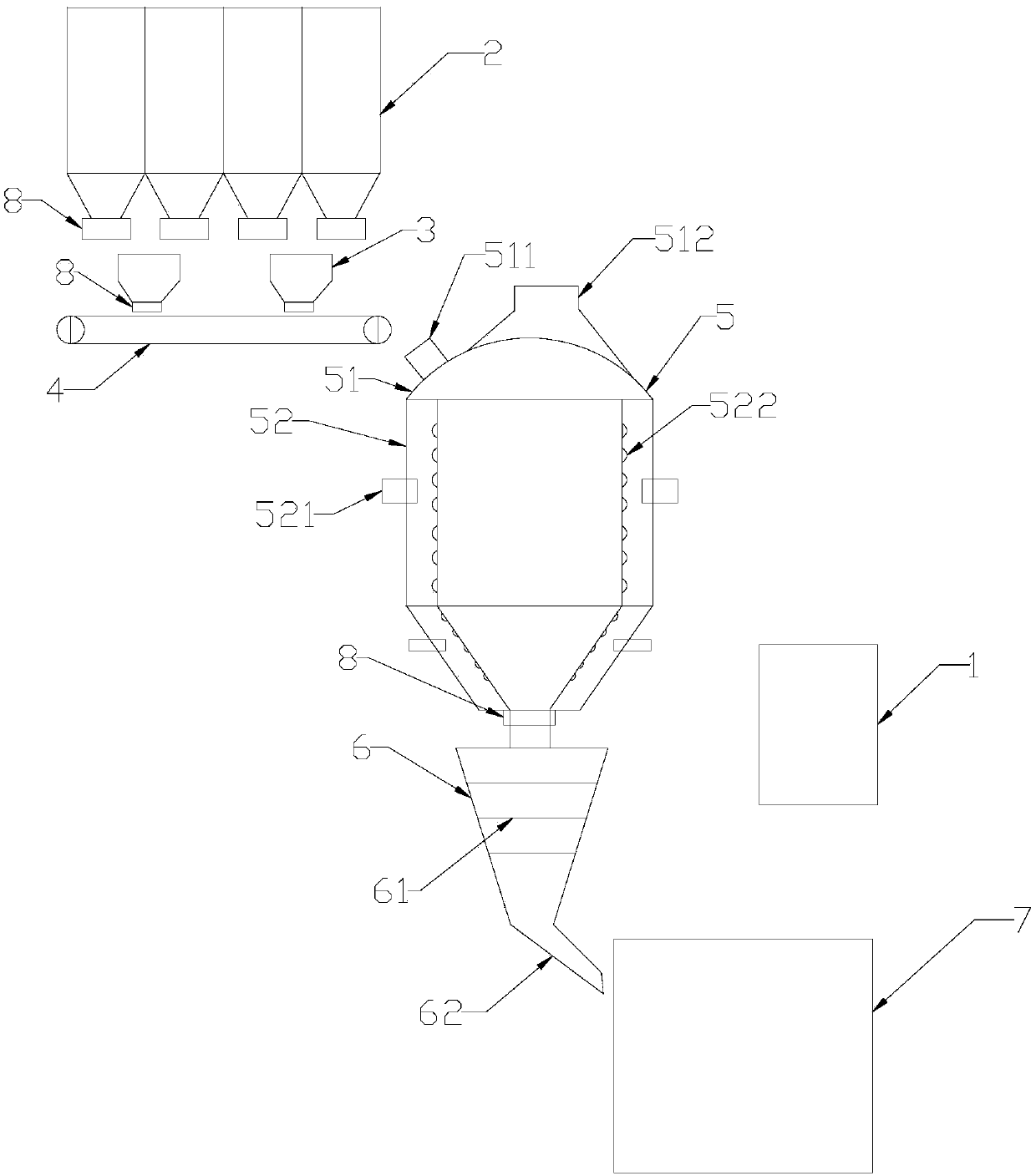

[0022] see figure 1 , the present invention provides an alloy baking system for a steelmaking converter, which includes a hot blast stove 1, an alloy silo 2, a weighing bucket 3, a belt conveyor 4, an alloy baking furnace 5 and a collecting bucket 6, and the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com