A balanced type Roots vacuum pump system and a control method thereof

A Roots vacuum pump, balanced technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of non-interchangeable use, poor versatility, and reduced effective pumping volume, so as to achieve convenient use and maintenance, and improve Stable and reliable, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

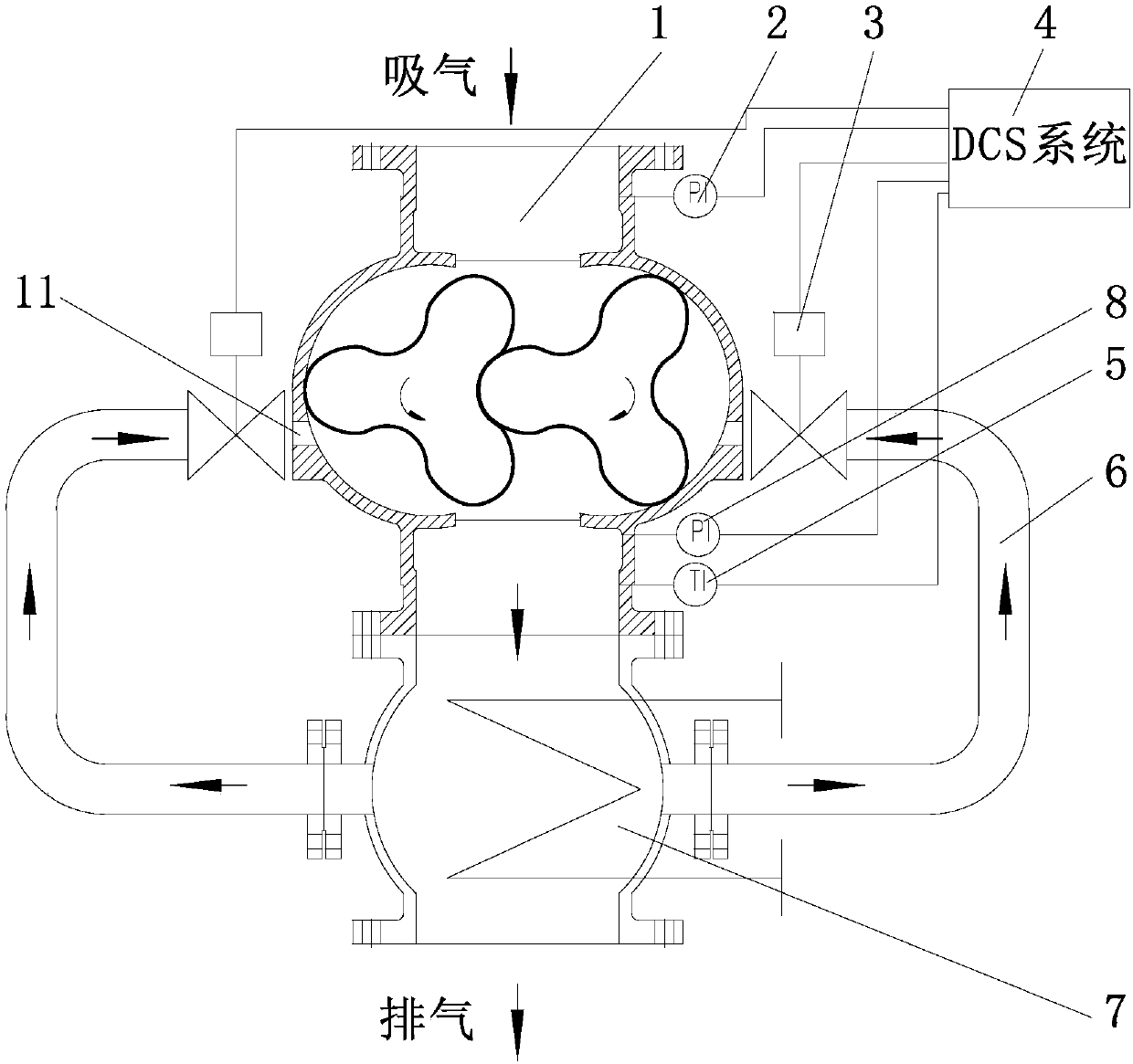

[0040] Such as figure 1 A balanced Roots vacuum pump system shown includes a Roots vacuum pump 1, a condenser 7, a detection mechanism and a DCS system 4; the two sides of the pump body of the Roots vacuum pump 1 are respectively provided with return ports 11, and the return ports 11 are An automatic regulating valve 3 is installed; the condenser 7 is arranged on the air outlet of the Roots vacuum pump 1, and the condenser 7 and the return port 11 are connected by a pipeline 6; the detection mechanism includes a pressure sensor a2, a pressure sensor b8 and a temperature sensor 5 , the pressure sensor a2 and the pressure sensor b8 are arranged on the intake pipeline and the discharge pipeline of the Roots vacuum pump 1 respectively, and the temperature sensor 5 is arranged on the discharge pipeline of the Roots vacuum pump 1 .

[0041] The DCS system 4 includes an input module, an output module, a storage module and a processor; the input module is electrically connected to the...

Embodiment 2

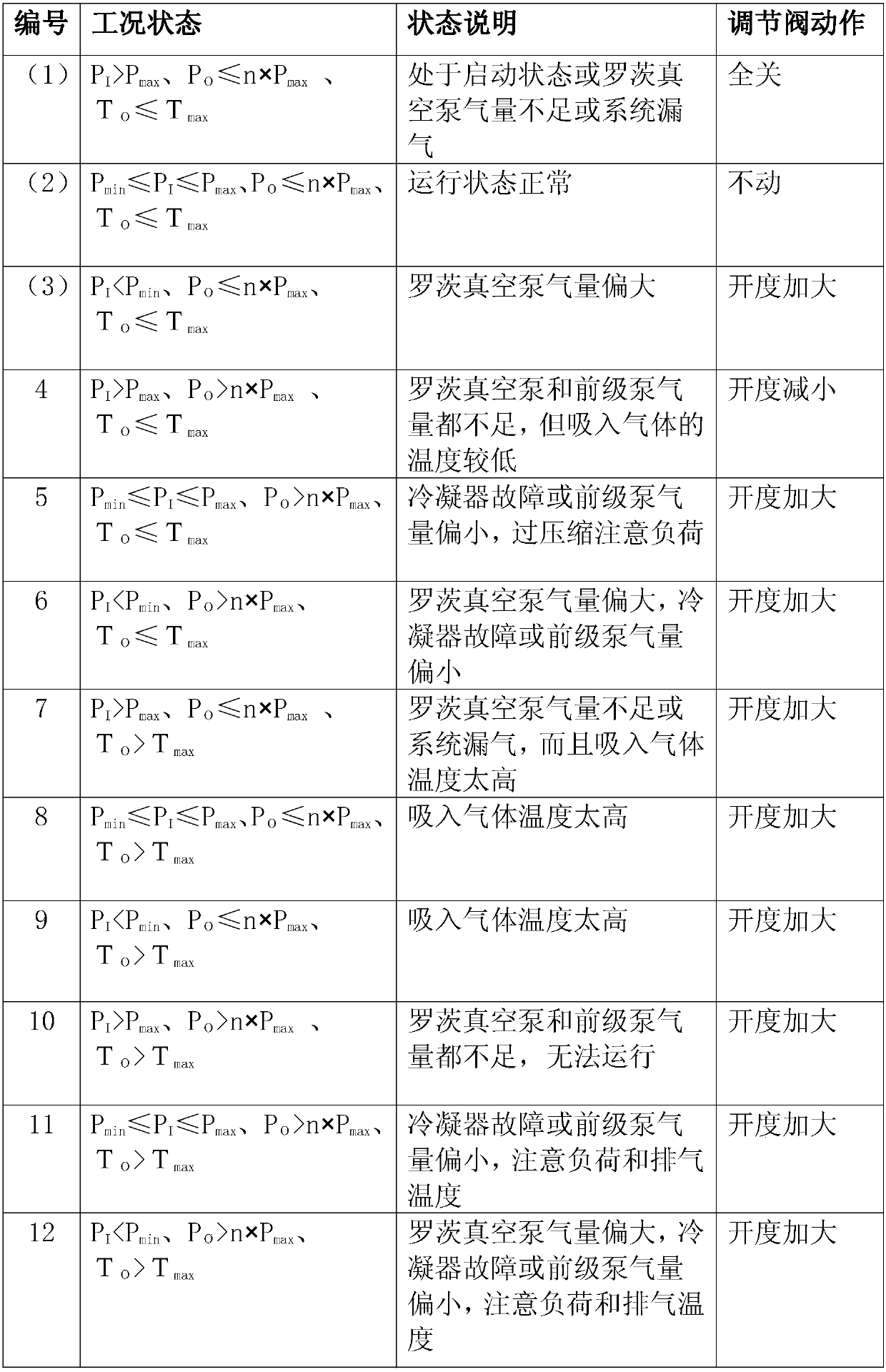

[0052] In this embodiment, the allowable range of gauge suction pressure required by the vacuum system is 40-60mbar(A), the compression ratio of Roots vacuum pump 1 is 3, the limit exhaust temperature is 100°C, and the duration of the abnormal state is allowed to be set. t = 10 minutes, ie P min =40mbar, P max =60mbar, n=3, T max = 100°C.

[0053] First, input the above predetermined value into the DCS system 4, and the system is controlled through the following steps.

[0054] S1, pressure sensor and temperature sensor 5 put the inlet pressure P of Roots vacuum pump 1 I , outlet pressure P 0 and outlet exhaust temperature T o are all transmitted to the DCS system 4;

[0055] S2. The DCS system 4 compares the received data with the set value to determine which state the balanced Roots vacuum pump system is in. For example, when the Roots vacuum pump 1 is just started, the system state is numbered (1);

[0056] S3. The DCS system 4 sends a signal to the automatic regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com