Suspension mechanical mixing device and mixer adopting same

A technology of mechanical mixing and mixing devices, which is applied in the preparation of test samples, etc., can solve the problems of unclean air bubble detection, difficult processing, and difficult removal of small air bubbles, so as to reduce the complexity of the instrument and improve the mixing effect , the effect of not easy to carry pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

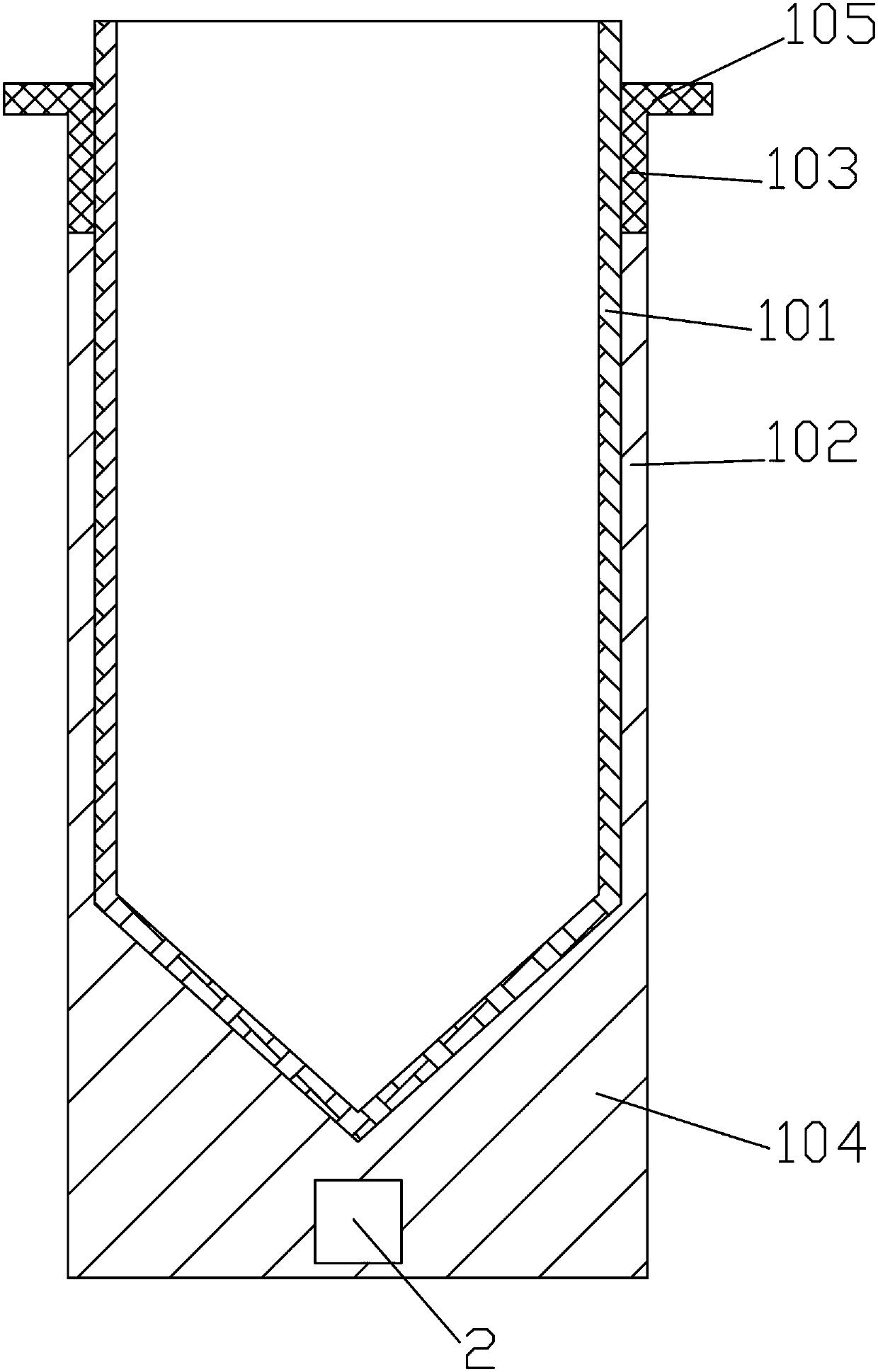

[0038] Embodiment one: see Figure 1-2 .

[0039] The invention discloses a suspension mechanical mixing device, which includes an oscillating mixing device 1, the oscillating mixing device includes an oscillating tube 102 for placing a mixing tube 101, the inner wall of the oscillating tube 102 is in contact with the outer wall of the mixing tube 101 Matching, the upper part of the oscillating tube 102 is provided with a flexible tissue 103 for connecting with the external support, the flexible tissue can also have a positioning ring 105 extending outward, and one or more than three The vibration mechanism 2.

[0040] Principle of use of the present invention:

[0041] First, pour the solution to be mixed into the mixing tube 101, turn on the power, and the vibrating mechanism 2 at the bottom of the oscillating tube 102 is energized to vibrate, and because the oscillating tube 102 matches the outer wall of the mixing tube 101, the force generated by the vibration is transmi...

Embodiment 2

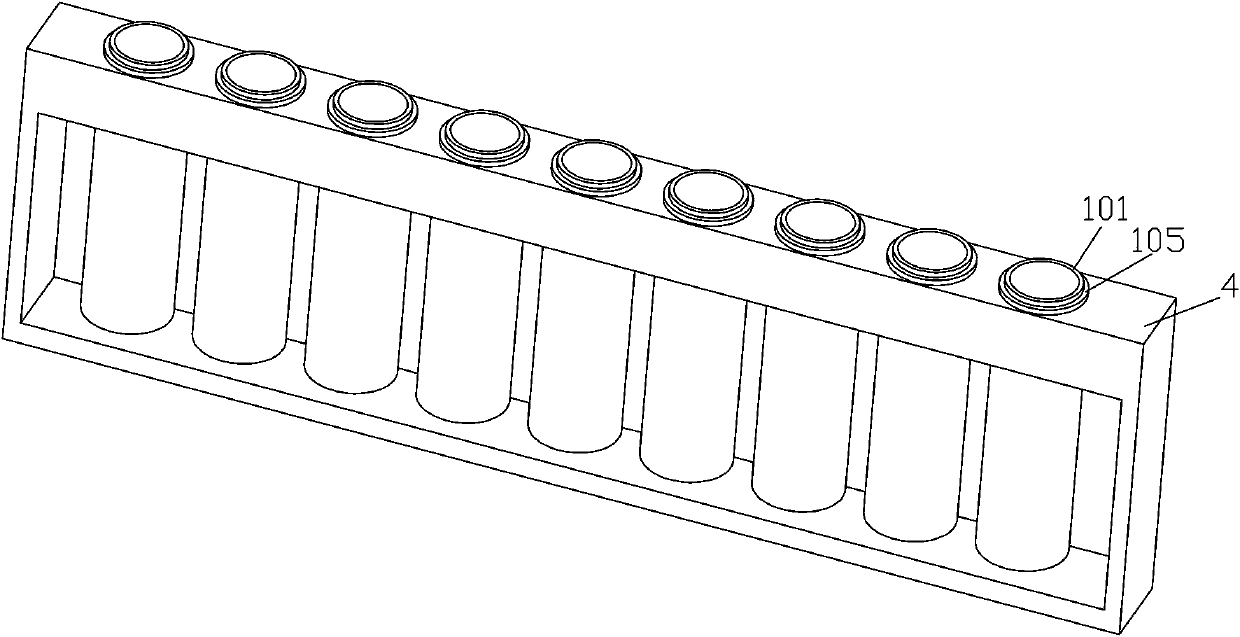

[0048] Embodiment two: see image 3 .

[0049] The same as Embodiment 1 will not be described in detail. The difference is that in this embodiment, the mixing devices are arranged in a linear array, and each mixing device 1 is inserted into a linear sampling mechanism 4. The sampling The mechanism 4 is provided with a row of through holes, and the through holes are used for plugging and fitting with the flexible tissue 103. The positioning ring 105 is located outside each through hole. Similarly, the flexible tissue 103 is inserted tightly between the through holes. An interference fit of extrusion deformation can be used. At the same time, a row of blind holes is provided at the bottom of the sampling mechanism 4 , and the bottoms of the mixing tubes are arranged above the blind holes without contacting them. The linear array is arranged in the sample feeding mechanism 4, and the sample feeding mechanism 4 is driven by an external force to translate to a preset position.

Embodiment 3

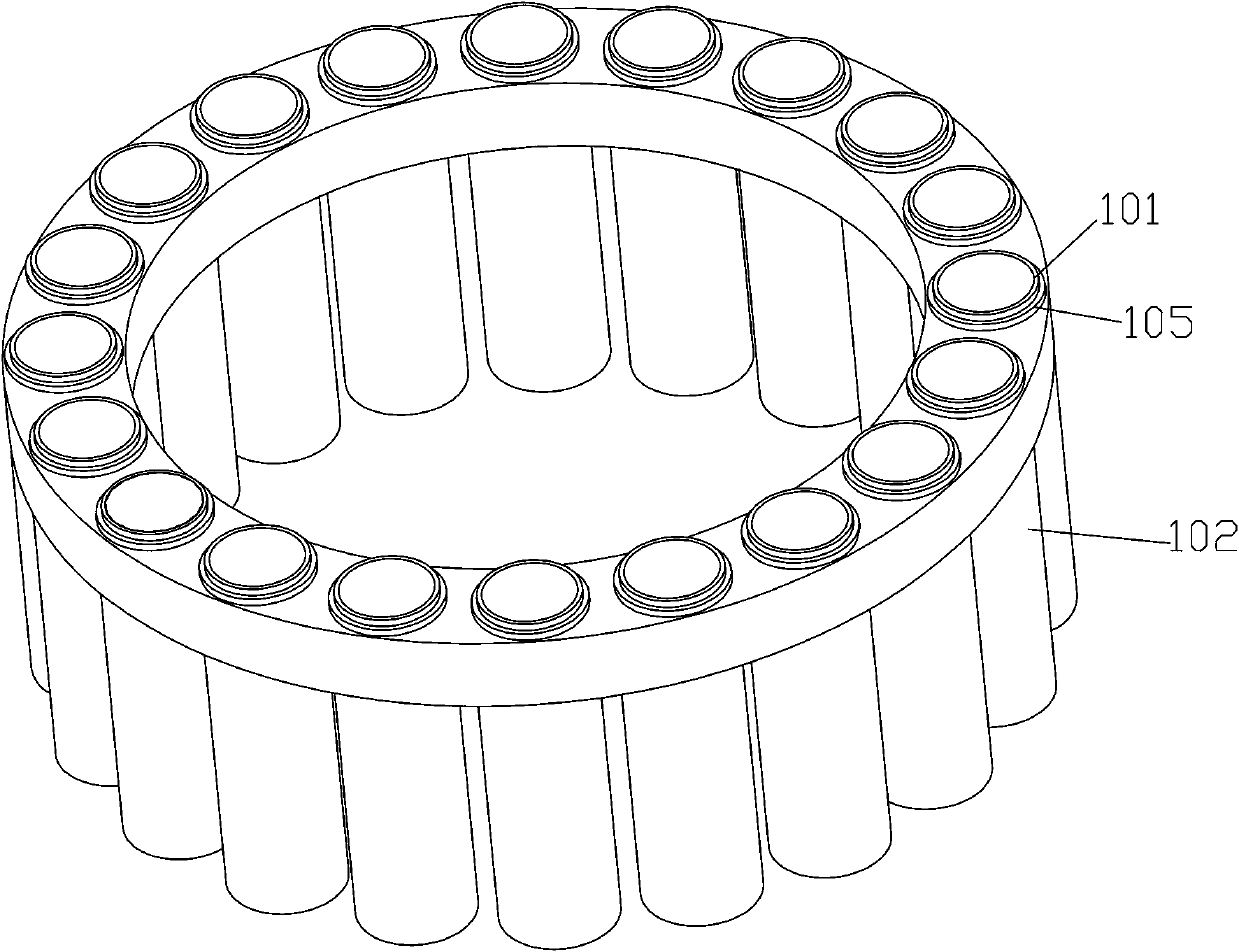

[0050]Embodiment three: see Figure 4 .

[0051] The same parts as those in Embodiment 1 will not be described in detail. The difference is that the circular array includes more than two layers, and the mixing devices of each adjacent layer are arranged alternately. In this embodiment, two layers of circular arrays are set up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com