Visual adjusting device for debugging photoelectric receiver optical shaft and mechanical shaft

A technology of photoelectric receiver and adjustment device, applied in the direction of coupling of optical waveguides, etc., can solve the problems of harsh working environment, high height of micrometer eyepiece, low working efficiency, etc., to improve working environment, improve economic efficiency, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

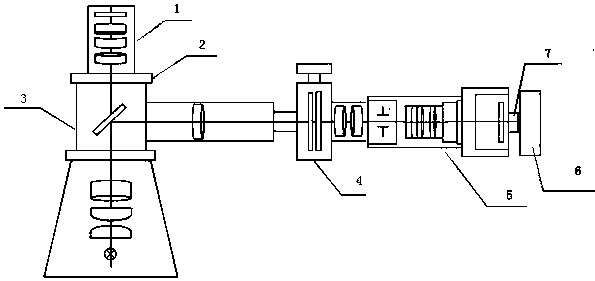

[0033] Such as image 3 As shown, a visual adjustment device for adjusting the optical axis and mechanical axis of a photoelectric receiver includes an objective lens adjustment device 3, an image observer 5 and an LED display 6, and one end of the image observer 5 is adjusted with the objective lens through a connector 12 The device 3 is fixedly connected, and the other end of the image observer 5 is electrically connected to the LED display 6 through the power interface 7 .

Embodiment 2

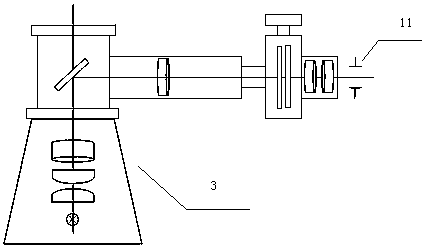

[0035] On the basis of Example 1, such as Figure 4 Shown, described image observer 5 is made up of CCD circuit board, objective lens holder 9 and image observer objective lens group 10; One end of objective lens holder 9 is fixed with image observer objective lens group 10, and the other end is fixed with CCD circuit board 8, The CCD circuit board 8 is provided with a regulated power supply, and the regulated power supply is electrically connected to the LED display 6 through the power interface 7 .

[0036] The image observer 5 is installed in the connector 12 , and the image observer objective lens group 10 is located at the exit pupil 11 of the measuring microscope 4 .

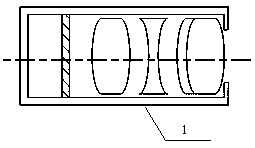

[0037] The image observer objective lens group 10 is composed of a convex lens and a concave lens, the end close to the CCD circuit board is a concave lens, and the end far away from the CCD circuit board is a convex lens.

Embodiment 3

[0039] On the basis of Example 2, such as Figure 5a and Figure 5b As shown, the objective lens holder 9 is a cylindrical body 91, one end of the cylindrical body is provided with a rectangular frame 92, and a fixing hole 93 is provided on the rectangular frame. The objective lens group 10 of the image observer is socketed on the cylindrical body 91 of the objective lens holder 9, and is fixed by dispensing glue, so as to avoid the displacement of the objective lens, resulting in blurred images, and the repeated work of readjustment. The objective lens holder 9 is fixed in the connector 12 through the fixing hole 93 on the rectangular frame 92 .

[0040] Such as Figure 6a and Figure 6b As shown, the connector 12 is a rectangular body with a cavity, the cavity is arranged along the length direction of the rectangular body, and the two ends of the cavity are large and the middle is small. The rectangular design of the connector makes it sit smoothly and ensures the accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com