Manufacturing method of lithium-ion batteries

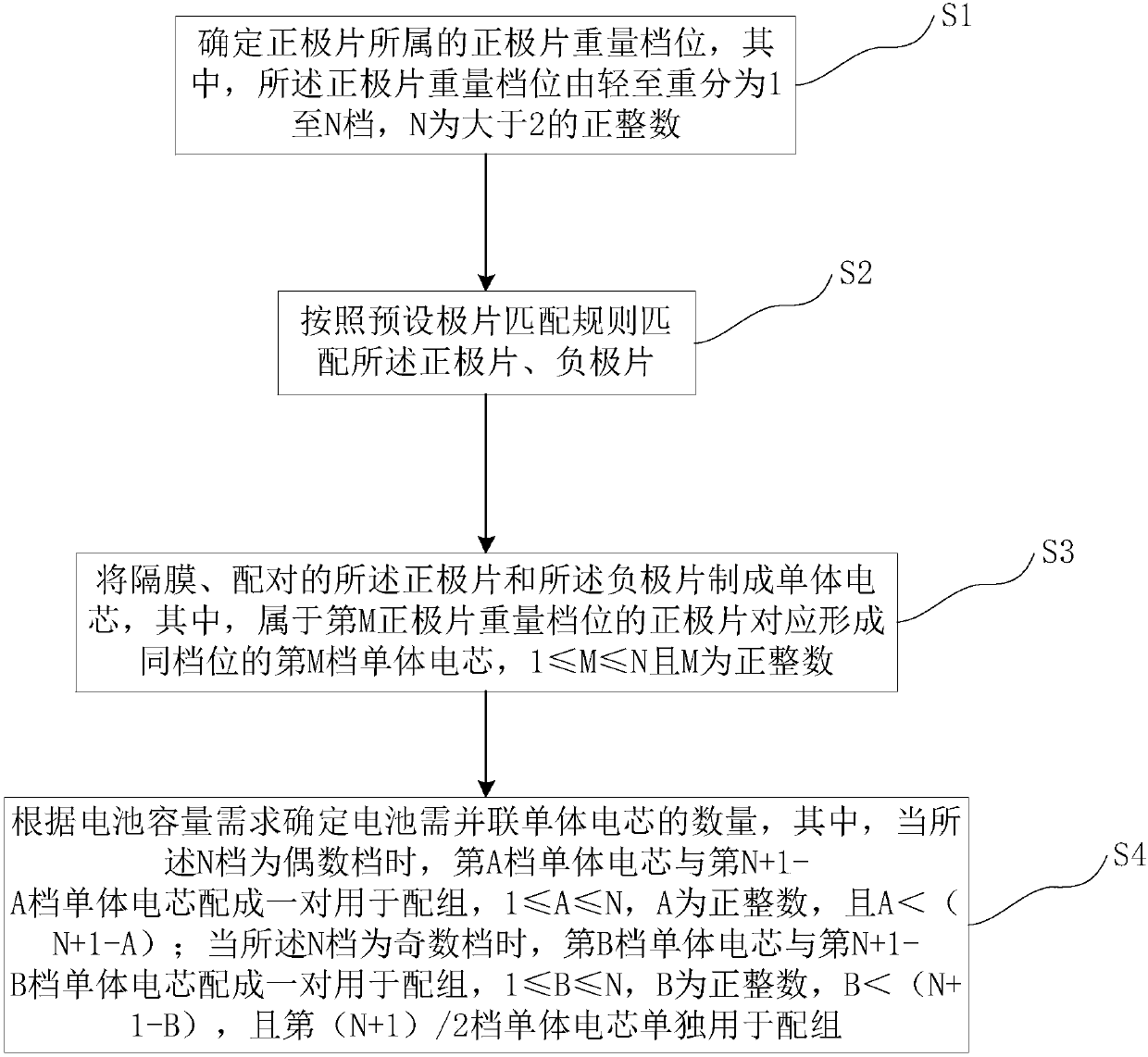

A manufacturing method and technology for lithium electronic batteries, which are applied in the manufacture of electrolyte batteries, secondary batteries, and final products, etc., can solve the problems of large capacity dispersion of single cells, low utilization rate of single cells, and reliability of battery packs. Reduce and other problems, to achieve the effect of reducing capacity dispersion and range, manufacturing method is simple and easy to operate, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Taking the production of a 60Ah lithium-ion battery with two single cells as an example, the single cells include 24 positive electrodes and 25 negative electrodes.

[0053] 1) Determine the weight range of the positive electrode sheet described in the positive electrode sheet. Among them, the positive electrode sheet with a weight range of 5.11g to 5.40g is divided into three grades: high, medium and low, and the weight range of each grade is 0.1g. as follows:

[0054] grade name

[0055] 2) Determine the weight range of the negative electrode sheet described in the negative electrode sheet. Among them, the negative electrode sheet with a weight range of 3.01g to 3.30g is divided into three grades: high, medium and low, and the weight range of each grade is 0.1g. as follows:

[0056] grade name

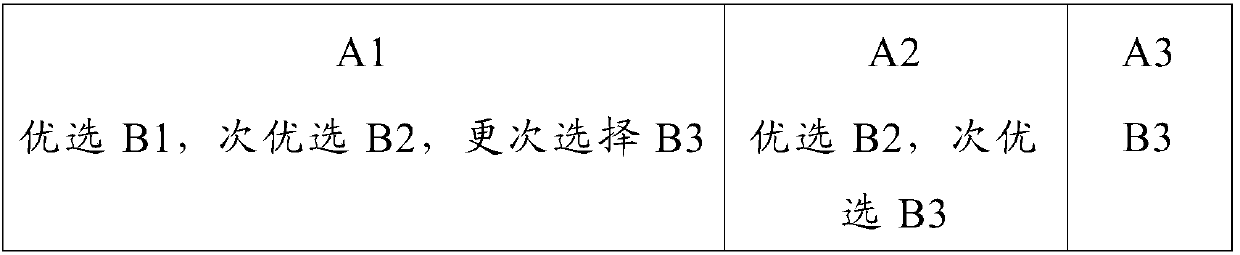

[0057] 3) The positive and negative electrodes are preferentially matched into a group according to the principle of matching the same grade. Each group c...

Embodiment 2

[0063] Taking the production of a 150Ah lithium-ion battery with 5 single cells as an example, the single cells include 24 positive electrodes and 25 negative electrodes.

[0064] 1) Determine the weight range of the positive electrode sheet described in the positive electrode sheet. Among them, the positive electrode sheet with a weight range of 5.11 to 5.40 is divided into three grades: high, medium and low. The weight range of each grade is 0.1g as the standard, and the grades are as follows:

[0065] grade name

[0066] 2) Determine the weight range of the negative electrode sheet described in the negative electrode sheet. Among them, the negative electrode sheet with a weight range of 3.01 to 3.30 is divided into three grades: high, medium and low. The weight range of each grade is 0.1g as the standard, and the grades are as follows:

[0067] grade name

[0068] 3) The positive and negative electrodes are preferentially matched into a group according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com