Pole piece of lithium ion cell and method to manufacture cell

A lithium-ion battery and pole piece technology, which is applied in the field of lithium-ion battery pole piece and the preparation of the lithium-ion battery, can solve the problems of battery cycle performance, uneven distribution of battery capacity, unstable product quality, etc. Achieve the effect of stable cycle performance, narrow distribution range and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

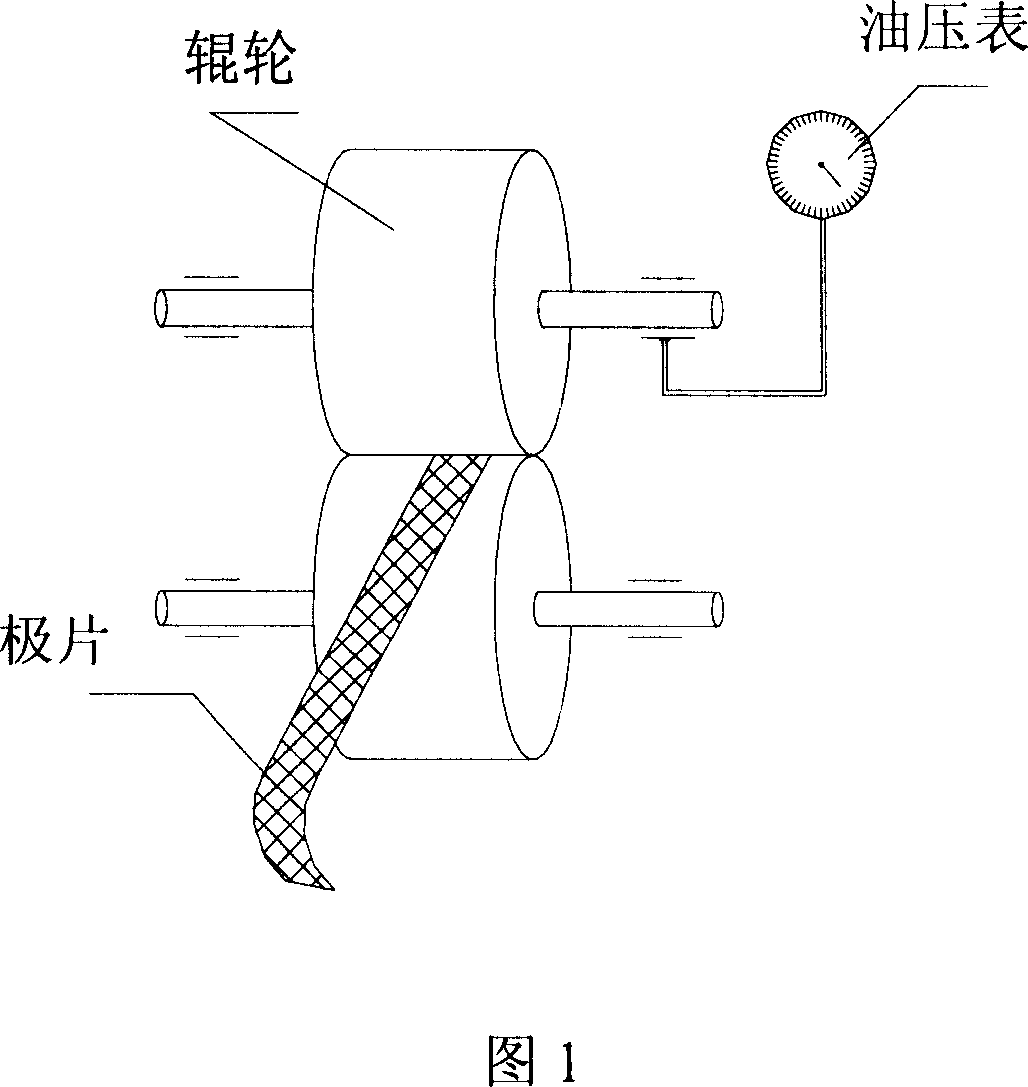

[0012] According to the preparation method of the lithium-ion battery provided by the present invention, preferably, the current collector containing the positive electrode active material, the conductive agent and the positive electrode binder and the collector containing the negative electrode active material and the negative electrode binder after drying Calendering is carried out, the calendering includes passing the pole piece through the gap between the two rollers of the calender, and applying pressure on the pole piece through the rollers, wherein, before applying the pressure, first adjust the two rollers of the calender Roller roller clearance, make 1 / 2(D 2 +D 1 )2 +9D 1 ), preferably 1 / 3 (D 2 +2D 1 )≤X≤1 / 7(D 2 +6D1); In the formula, X is the roller gap between the two rollers of the calender, D 1 is the thickness of the front pole piece passing through the gap between the two rollers of the calender, D 2 It is the thickness of the back pole piece passing throu...

Embodiment 1

[0032] This example is used to illustrate the preparation of the lithium ion secondary battery provided by the present invention.

[0033] (1) Preparation of positive electrode

[0034] 100 g of the positive active ingredient LiCoO 2 1. Add 3 grams of binder polyvinylidene fluoride and 3 grams of conductive agent acetylene black into 50 grams of N-methylpyrrolidone, and then stir in a mixer to form a uniform positive electrode slurry.

[0035] The slurry was evenly coated on both sides on an aluminum foil with a thickness of 16 μm, dried at 150° C., and cut to obtain a positive electrode sheet with a size of 340×41.5×0.205 mm. Then, the pole piece was rolled on the calender. Before the rolling, the roller gap X between the two rollers was adjusted so that X=0.196 mm. After the calendering, a positive pole piece with a thickness of 0.145 mm was obtained. It contains 5.8 grams of active ingredient LiCoO 2 .

[0036] (2) Preparation of negative electrode

[0037] Add 100 gra...

Embodiment 2-5

[0042] This example is used to illustrate the preparation of the lithium ion secondary battery provided by the present invention.

[0043] Prepare the battery pole piece and the battery according to the method of Example 1, the difference is that before the positive pole piece is rolled, the roller gap X between the two rollers is adjusted so that X = 0.195 mm, 0.193 mm, 0.190 mm respectively mm, 0.185 mm; before calendering the negative electrode sheet, adjust the roller gap X between the two rollers so that X = 0.198 mm, 0.195 mm, 0.192 mm, 0.186 mm respectively. Square aluminum shell lithium-ion secondary batteries 043450A3B4-B6, 043450A3B7-B8, 043450A3B10-B12, and 043450A3B13-B15 with a size of 50×34×4.5 mm were prepared respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com