High-safety switch cabinet

A high-safety, switchgear technology, applied in the direction of the substation/distribution device casing, etc., can solve the problem of the lock tongue not easily turning, hitting the door frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

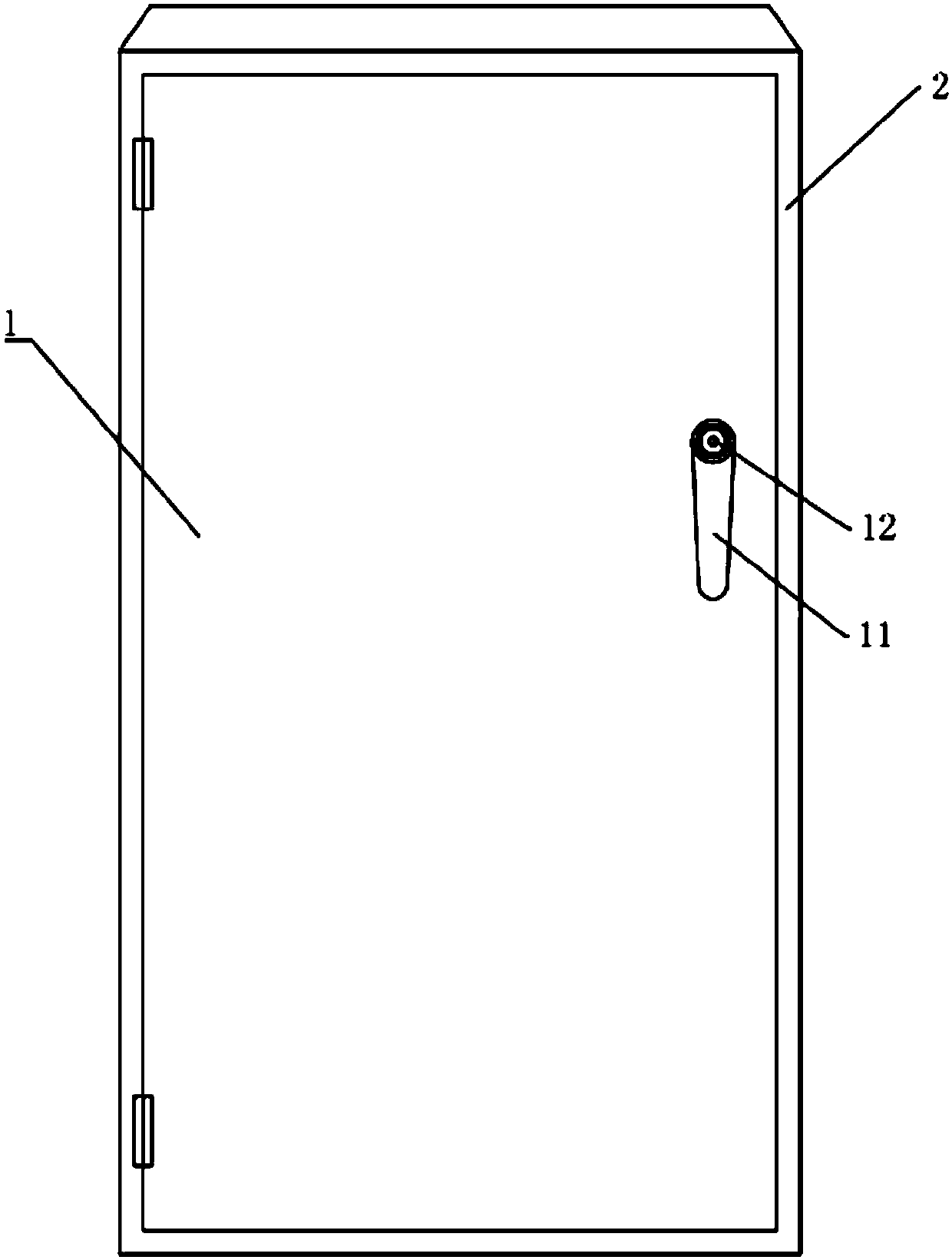

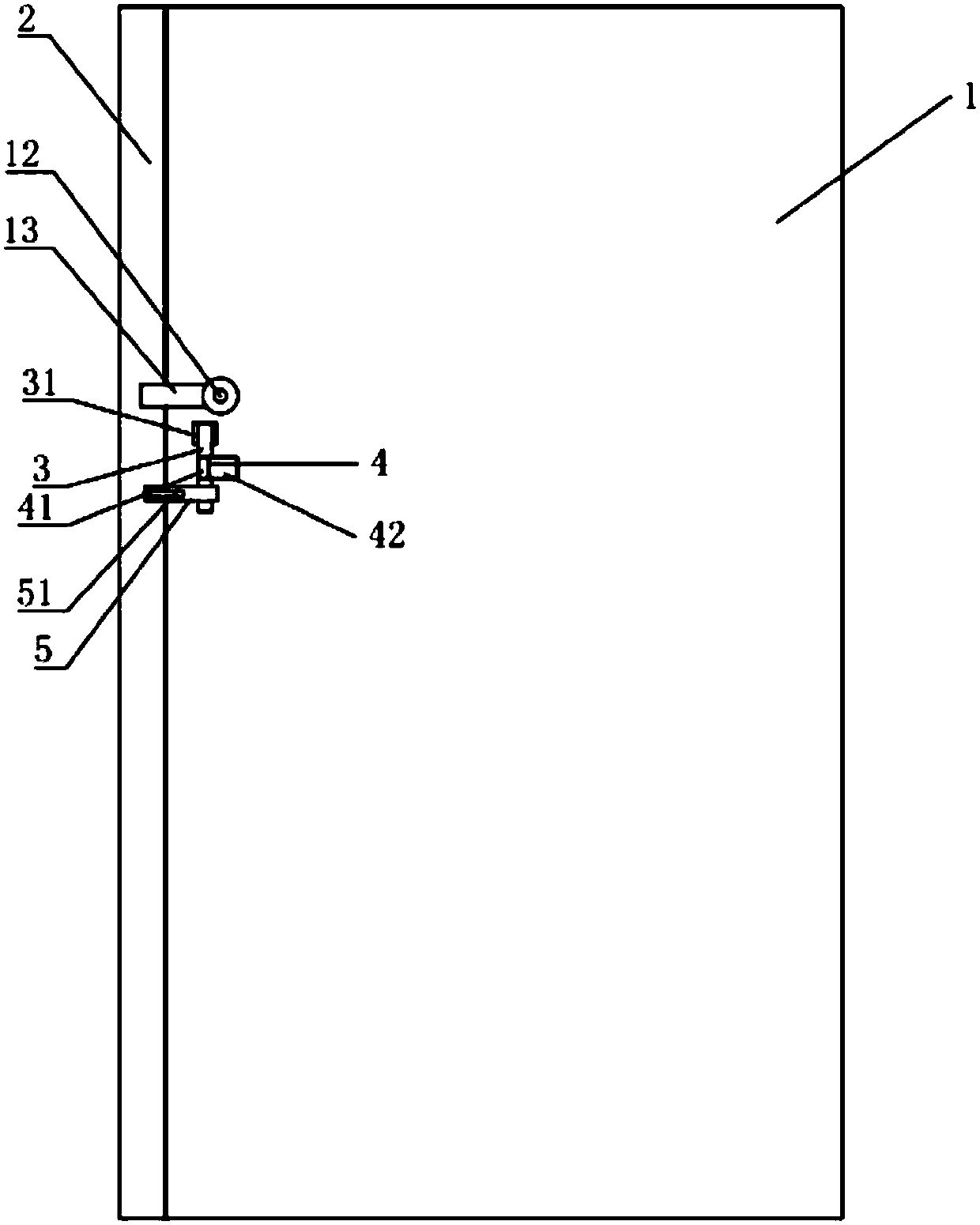

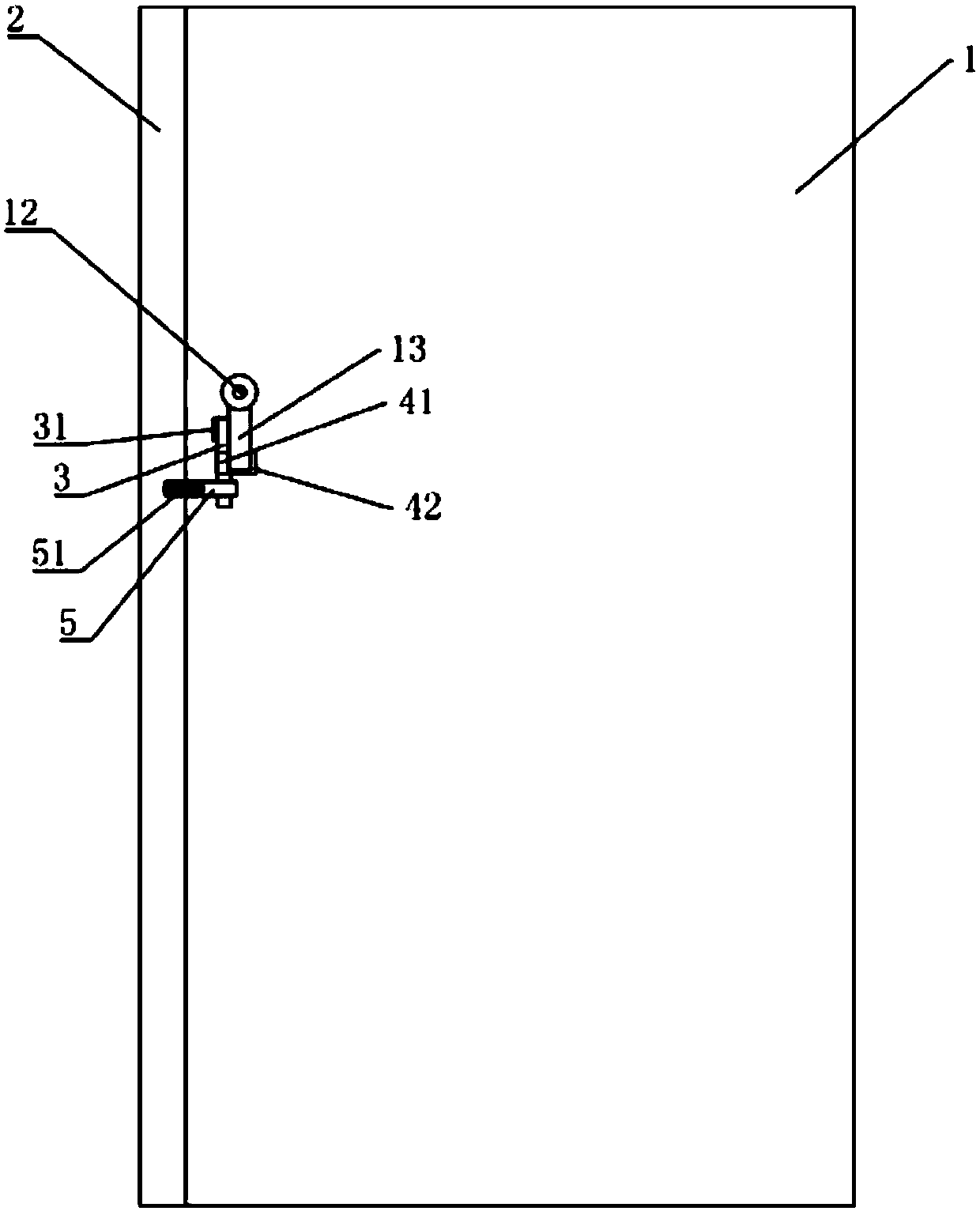

[0031] A high security switchgear such as figure 1 , 2 As shown in and 3, a cabinet door 1 and a door frame 2 are included. A handle 11 is provided on the cabinet door 1. The upper end of the handle 11 penetrates into the cabinet door 1 and is provided with a rotating shaft 12. The end of the rotating shaft 12 located on the inside of the cabinet door 1 is set toward the door frame 2. Dead bolt 13 is arranged. When the cabinet door 1 is closed, the handle 11 is in a vertical state, and the dead bolt 13 is in a horizontal state, and the dead bolt 13 clamps the door frame 2, thereby locking the cabinet door 1 . When opening the cabinet door 1, the dead bolt 13 is rotated downward by turning the handle 11, so that the dead bolt 13 is detached from the interference with the door frame 2, and the cabinet door 1 is opened.

[0032] An elastic sheet 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com