Roots vacuum unit self-cleaning cooling mechanism

A technology of vacuum unit and Roots vacuum pump, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc. It can solve problems such as clogging of rotors and cavities, parking, and reducing the pumping efficiency of vacuum units, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

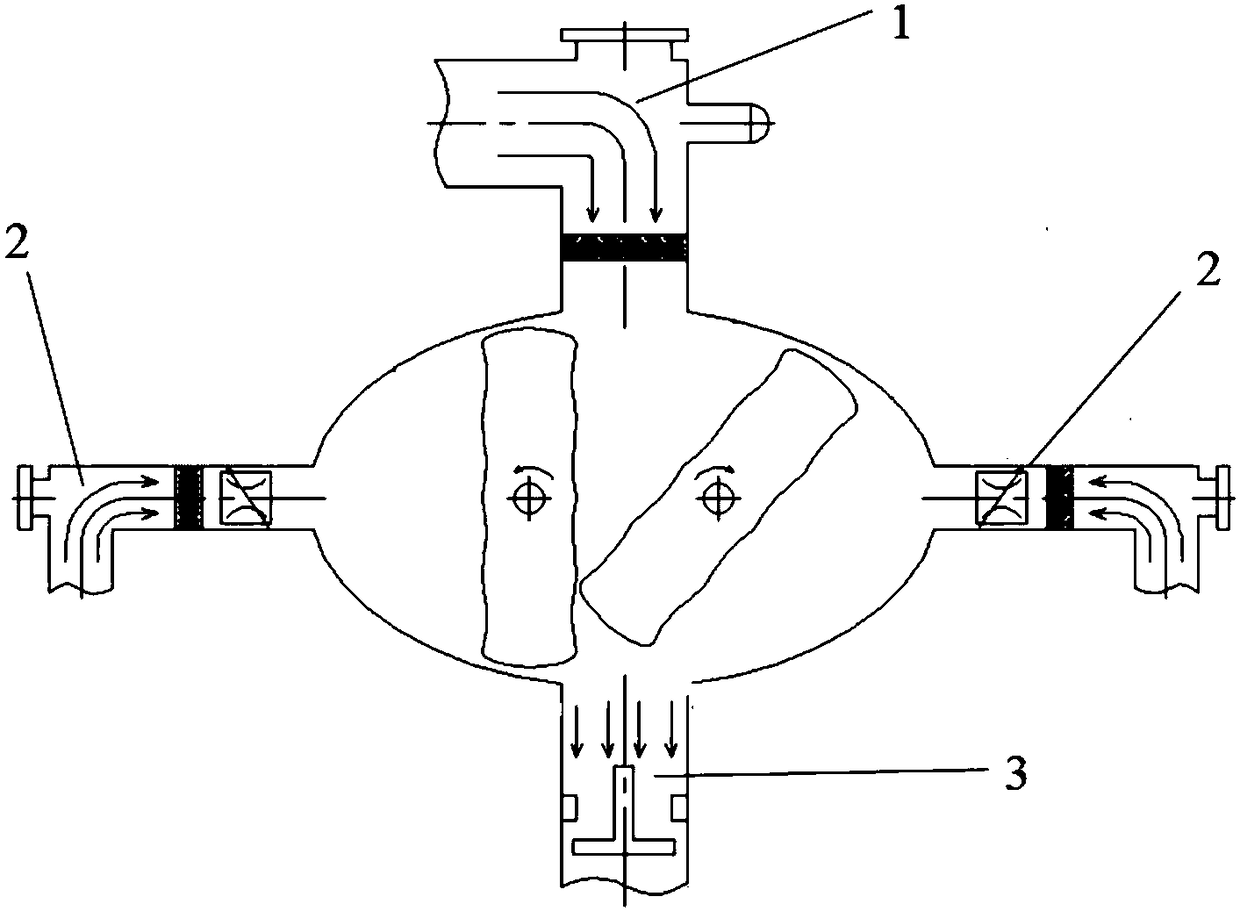

[0039] The invention discloses a Roots vacuum unit self-cleaning and cooling mechanism, such as Figure 1 to Figure 4 As shown, the device includes at least:

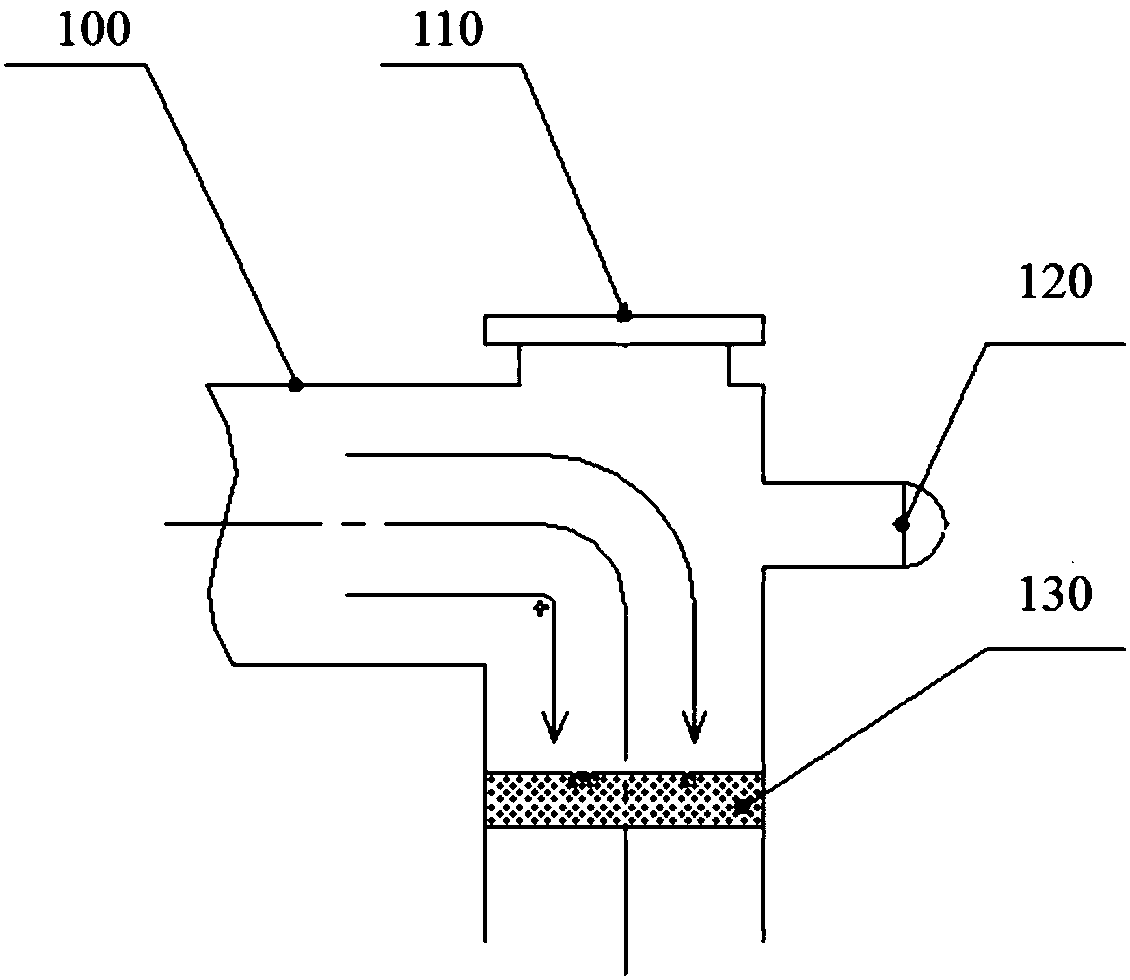

[0040] The impurity removal component 1 is arranged on the intake end of the Roots vacuum pump; the impurity removal component comprises an air intake pipeline 100 which is sealedly connected with the intake end of the Roots vacuum pump, and is arranged in turn on the air intake pipeline An observation window 110, an inflation valve 120 and a first filter 130; the first observation window 110 is used to observe the first filter 130;

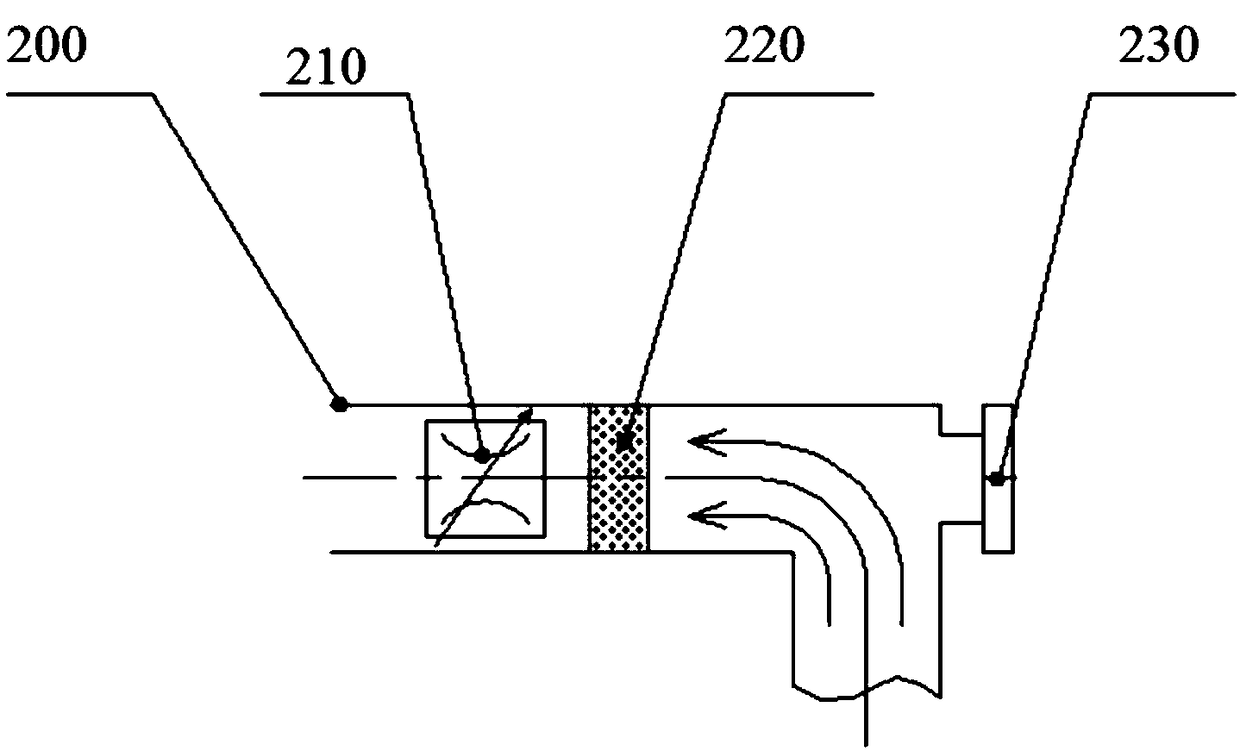

[0041] At least one air supply part 2, which provides cold air to the Roots vacuum pump; the air supply part 2 includes a cold air delivery pipeline 200, and a gas flow regulating valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com