Exposure dose uniformity by rotation, translation and variable process conditions

A technology of exposure dose and uniformity, applied in microlithography exposure equipment, photolithography exposure equipment, optics, etc., can solve problems such as light bar intensity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

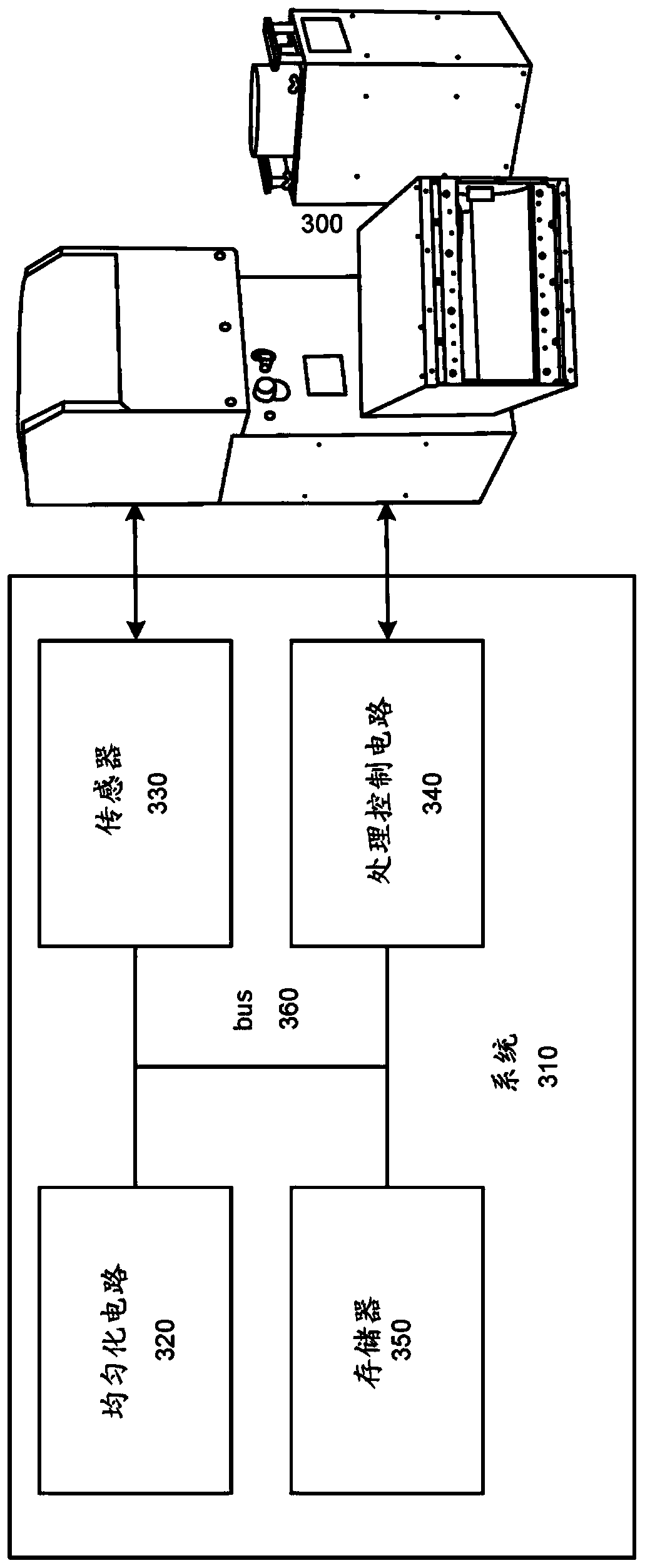

[0032] image 3 is a dose homogenization system 310 for a UV source 300 according to an embodiment of the invention. System 310 may include one or more processing circuits (eg, equalization circuit 320 and / or processing control circuit 340 ), one or more sensors 330 , memory 350 , and / or other elements. Sensor 330 may measure lamp intensity and decay of UV source 300 . Uniformization circuitry 320 may determine UV source 300 system settings to optimize UV light quantitative uniformity. Process control circuitry 340 may control elements of UV source 300 (eg, motors, UV lights, etc.) to achieve a determined UV optimization. The functions and features of these elements 320-350 are described in more detail below. These elements 320 - 350 may be interconnected via a bus 360 . Some elements may be combined (eg, a single processing circuit may perform the functions of equalization circuit 320 and processing control circuit 340 in some embodiments). In some implementations, ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com