UV (ultraviolet) varnish high-efficiency stirring equipment for production of outer casing of air detector

A technology of air detector and mixing equipment, which is applied in the direction of mixer accessories, chemical instruments and methods, and dissolution, etc., and can solve problems such as poor mixing effect, waste of UV varnish, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

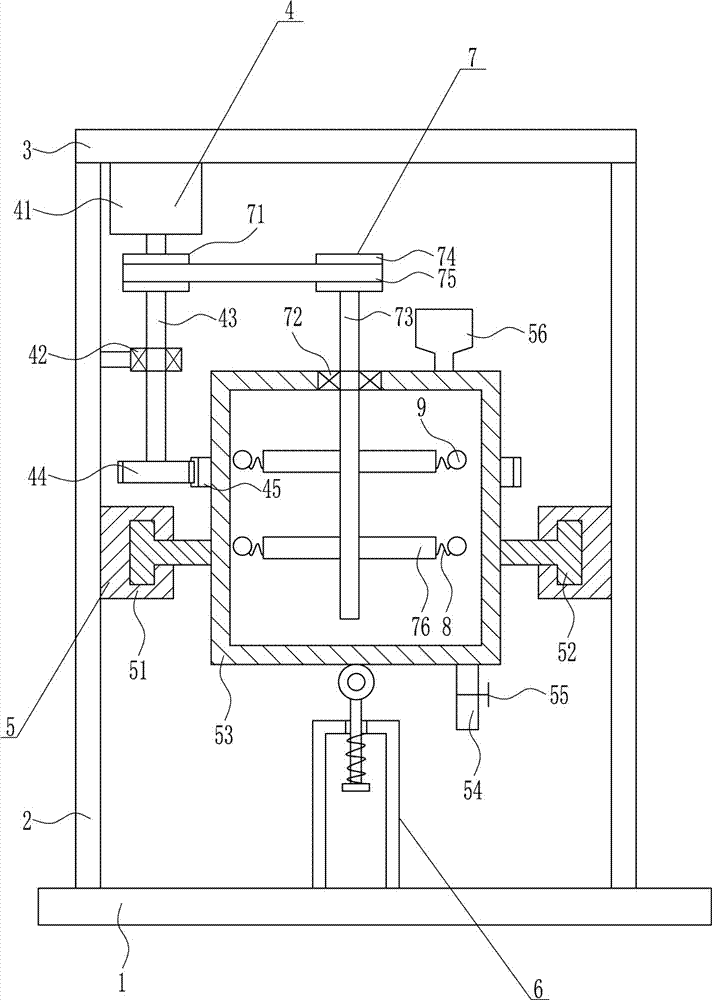

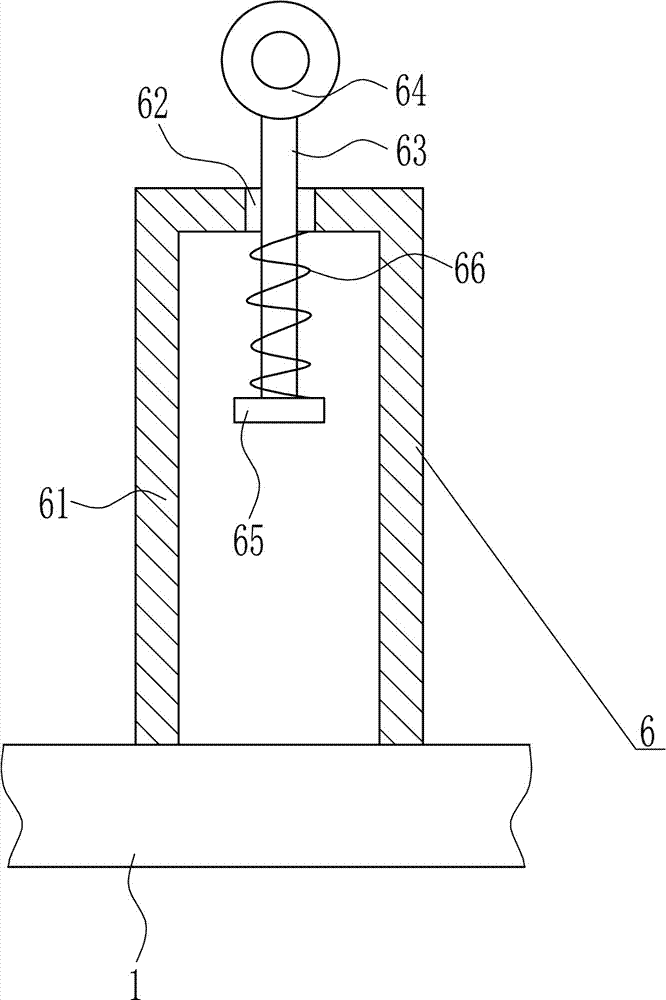

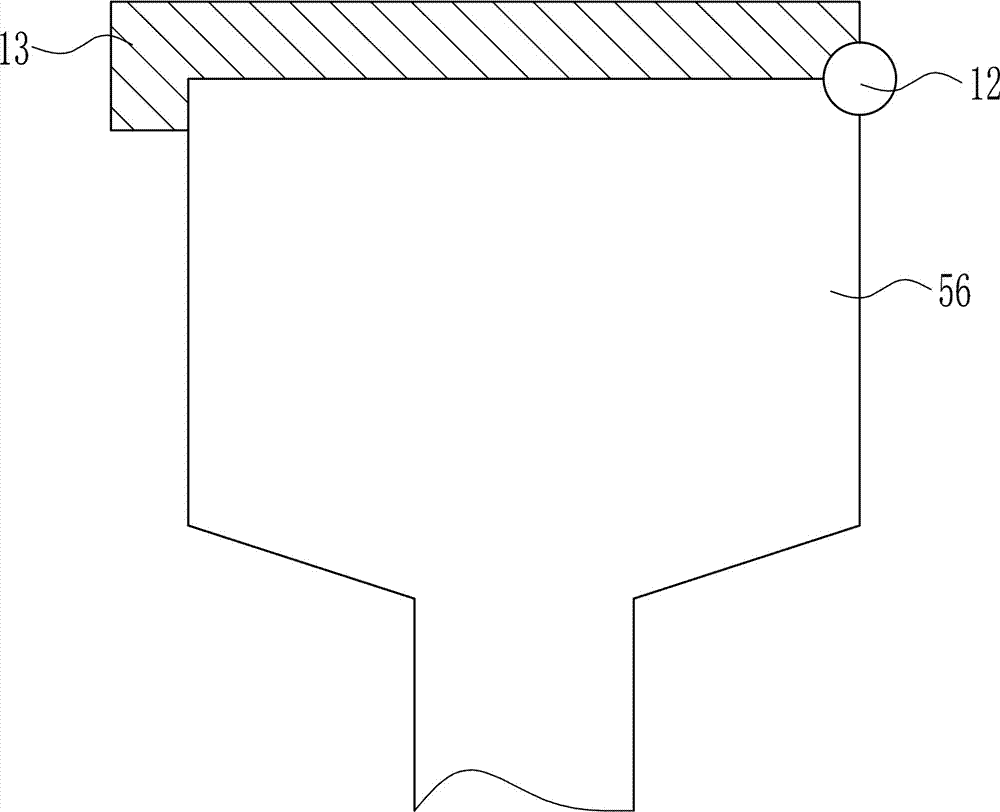

[0037] A high-efficiency mixing equipment for UV varnish used in the production of air detector shells, such as Figure 1-7 As shown, it includes a base plate 1, a bracket 2, a top plate 3, a rotating device 4 and a first stirring device 5. The top of the base plate 1 is vertically installed with a bracket 2 in a symmetrical manner connected by bolts, and the middle part between the two brackets 2 is provided with The first stirring device 5, the top between the two supports 2 is horizontally connected with a top plate 3 by bolt connection, the left side of the top plate 3 bottom is provided with a rotating device 4, the rotating part of the rotating device 4 is connected with the stirring part of the first stirring device 5 connect.

Embodiment 2

[0039] A high-efficiency mixing equipment for UV varnish used in the production of air detector shells, such as Figure 1-7 As shown, it includes a base plate 1, a bracket 2, a top plate 3, a rotating device 4 and a first stirring device 5. The top of the base plate 1 is vertically installed with a bracket 2 in a symmetrical manner connected by bolts, and the middle part between the two brackets 2 is provided with The first stirring device 5, the top between the two supports 2 is horizontally connected with a top plate 3 by bolt connection, the left side of the top plate 3 bottom is provided with a rotating device 4, the rotating part of the rotating device 4 is connected with the stirring part of the first stirring device 5 connect.

[0040] The rotating device 4 includes a first motor 41, a first bearing seat 42, a first rotating shaft 43, a first gear 44 and a ring gear 45, and the left side of the bottom of the top plate 3 is equipped with the first motor 41 by means of bo...

Embodiment 3

[0042] A high-efficiency mixing equipment for UV varnish used in the production of air detector shells, such as Figure 1-7 As shown, it includes a base plate 1, a bracket 2, a top plate 3, a rotating device 4 and a first stirring device 5. The top of the base plate 1 is vertically installed with a bracket 2 in a symmetrical manner connected by bolts, and the middle part between the two brackets 2 is provided with The first stirring device 5, the top between the two supports 2 is horizontally connected with a top plate 3 by bolt connection, the left side of the top plate 3 bottom is provided with a rotating device 4, the rotating part of the rotating device 4 is connected with the stirring part of the first stirring device 5 connect.

[0043] The rotating device 4 includes a first motor 41, a first bearing seat 42, a first rotating shaft 43, a first gear 44 and a ring gear 45, and the left side of the bottom of the top plate 3 is equipped with the first motor 41 by means of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com