Method for preparing microwave solid-state circuit corrosion-resistant liquid-cooled cold plate

A liquid-cooled cold plate, solid-state circuit technology, applied in electrical digital data processing, cooling/ventilation/heating transformation, instruments, etc., to achieve the effects of less environmental pollution, compact structure, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

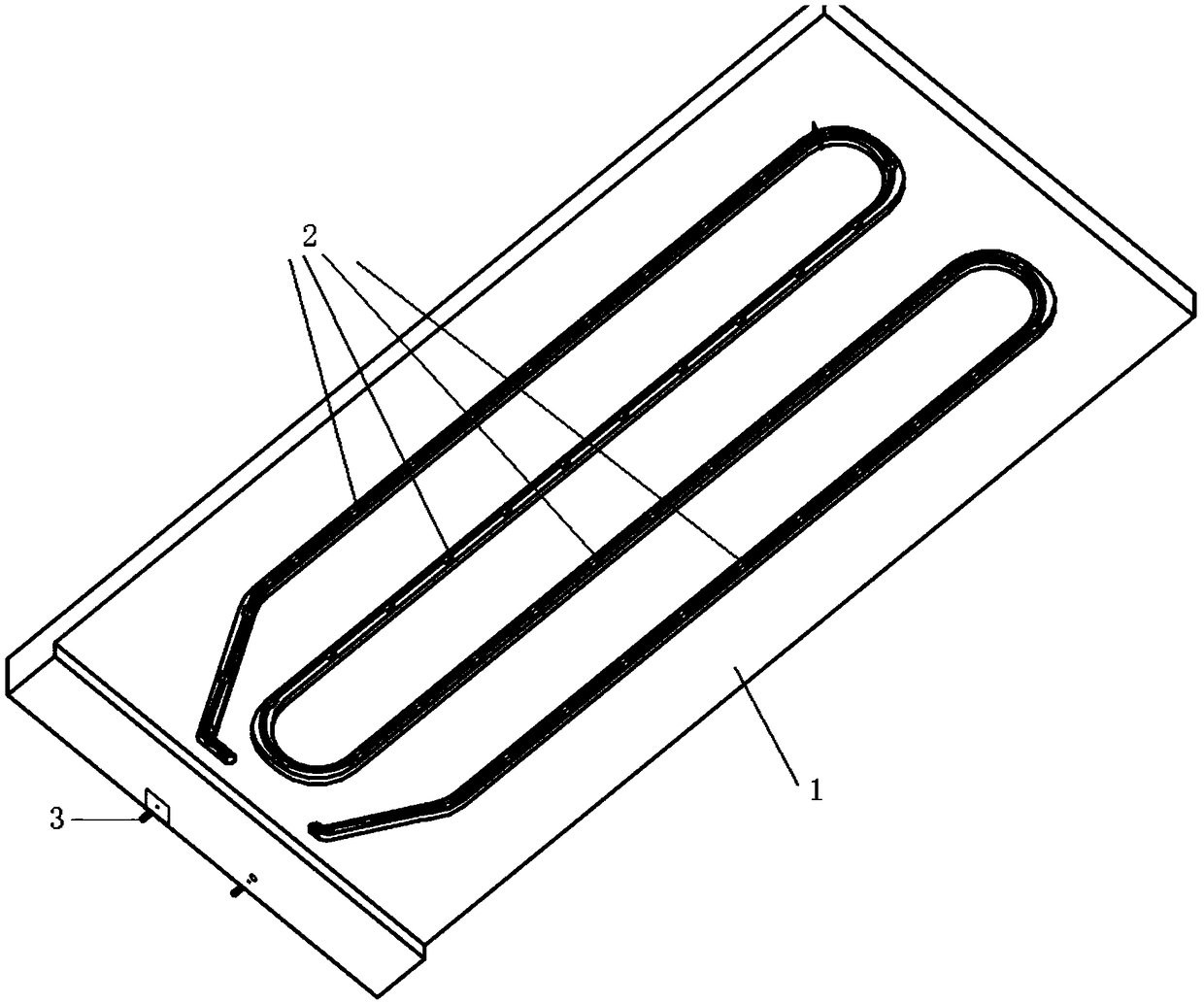

[0016] refer to figure 1 , figure 2 . According to the present invention, aiming at the complex flow channel structure, a thermal simulation fluid model of the liquid-cooled cold plate is established, and the flow characteristics, pressure loss characteristics and heat transfer characteristics of various flow channel structures are compared and analyzed in the thermal simulation analysis software, Combined with the flow channel size of the aluminum alloy cold plate base material, a convection-thermal conduction coupling model is established to obtain the temperature and pressure distribution of the cold plate, and the flow channel structure with better heat dissipation performance is obtained, and then according to the selected cold plate flow channel structure, Casting temperature and micro-arc oxidation technical conditions, design figure 1 The conductive electrode 3 and the ceramic ring tube 2 are designed for the conductive electrode 3 and the ceramic ring tube 2. In or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com