U-shaped bent waveguide processing method

A curved waveguide and U-shaped technology, applied in the field of U-shaped curved waveguide processing, can solve the problems of high processing difficulty, rising processing cost, unreasonable, etc., and achieve the effect of improving wartime repair and maintenance and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

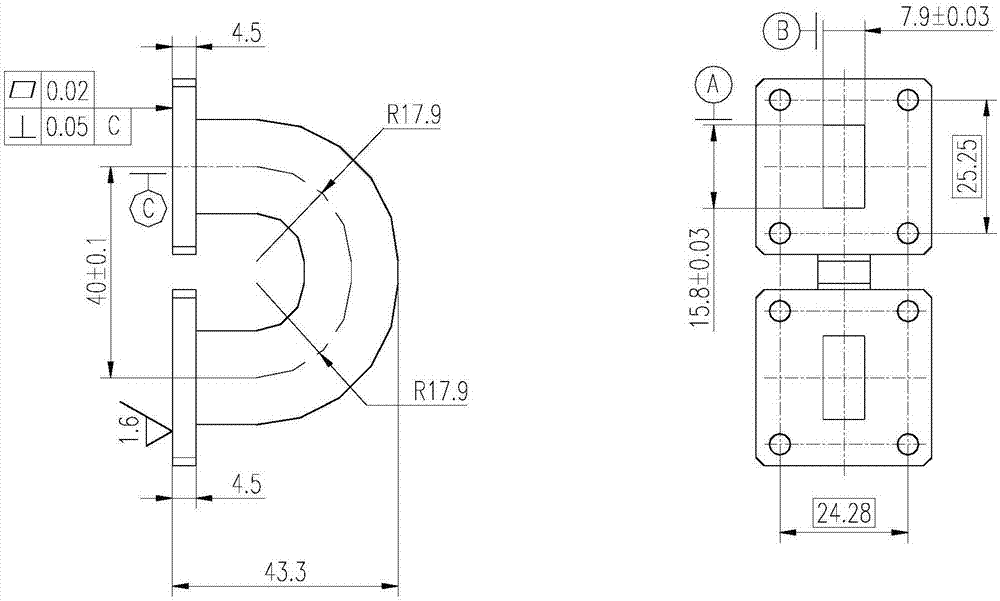

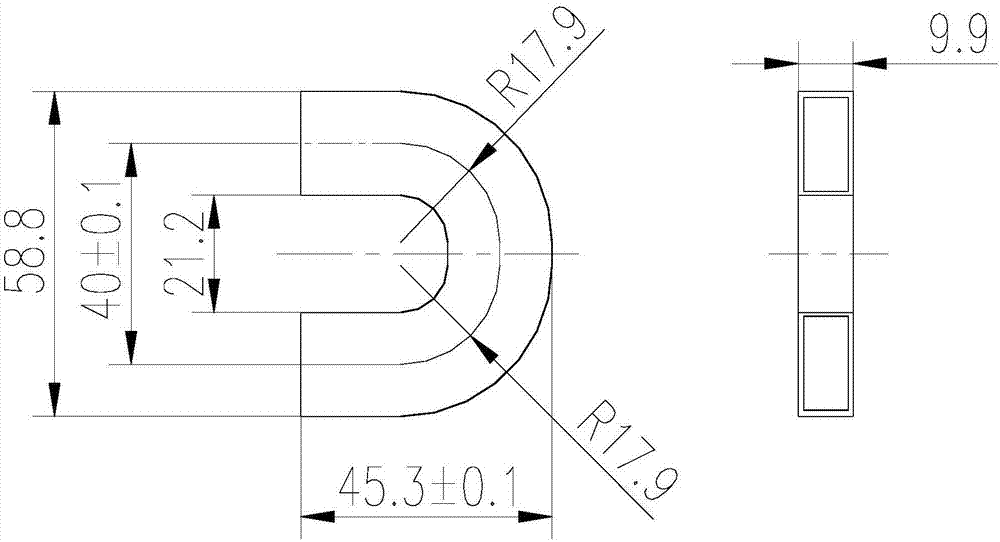

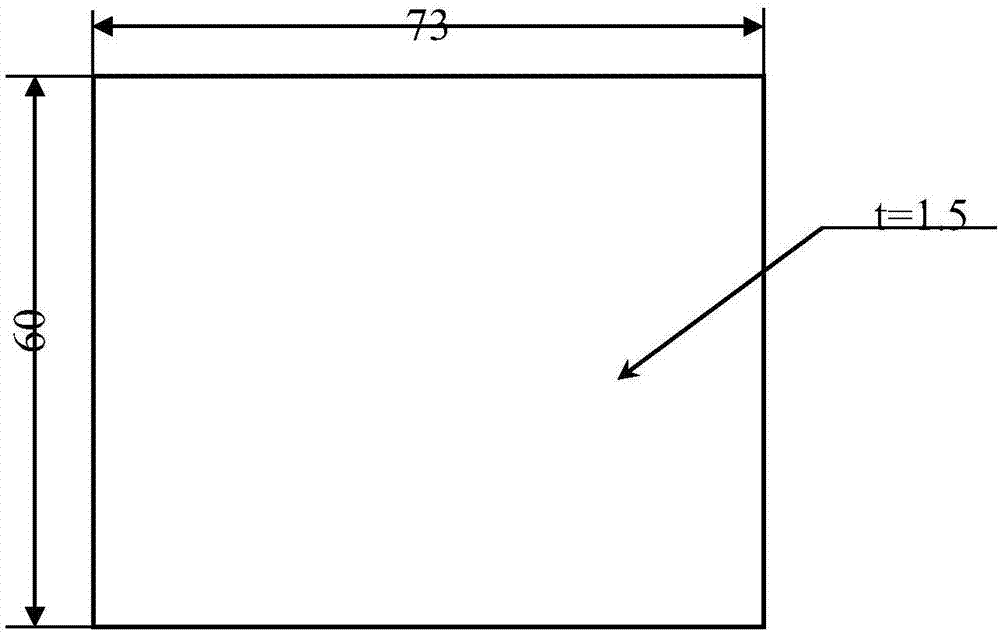

[0023] The following problems must be solved when processing the U-bend waveguide used in electromagnetic wave radar: It is necessary to meet the final processing accuracy and surface roughness of the U-bend waveguide used in electromagnetic wave radar, that is, the U-bend waveguide used in electromagnetic wave radar. The surface roughness of the cavity is 1.6um, and the surface roughness of the aluminum alloy sheet welded with it is also 1.6um. At the same time, it must be ensured that the processing method selected by the present invention can complete the processing with high quality and quantity. The technical method adopted in the present invention is: replace the special-made waveguide blank material with the U-shaped curved waveguide blank made of aluminum alloy plates with different thicknesses through milling and welding, so that the original fitter is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com