High-position two-way collection and storage integrated system and collection and storage method thereof

An integrated, high-level technology, applied in the direction of packaging automatic control, conveyor objects, packaging, etc., can solve problems affecting packaging, conveying efficiency, time-consuming, low production packaging efficiency, etc., to improve product output efficiency, improve production efficiency, The effect of improving the overall production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

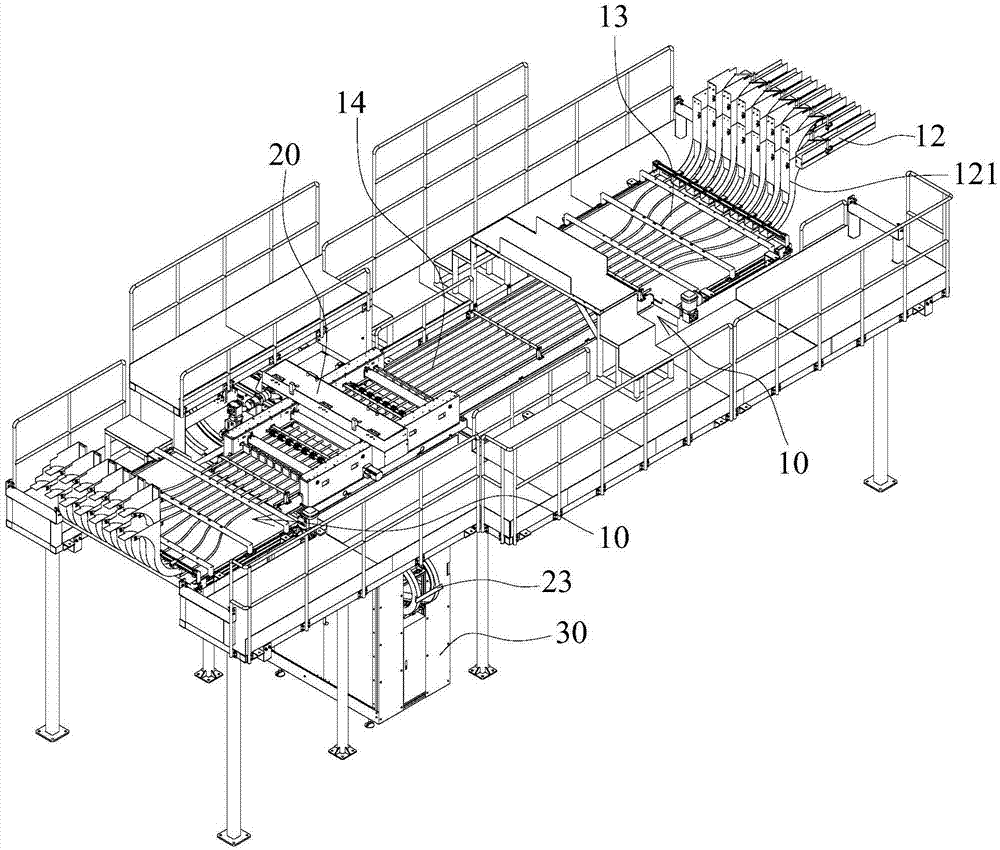

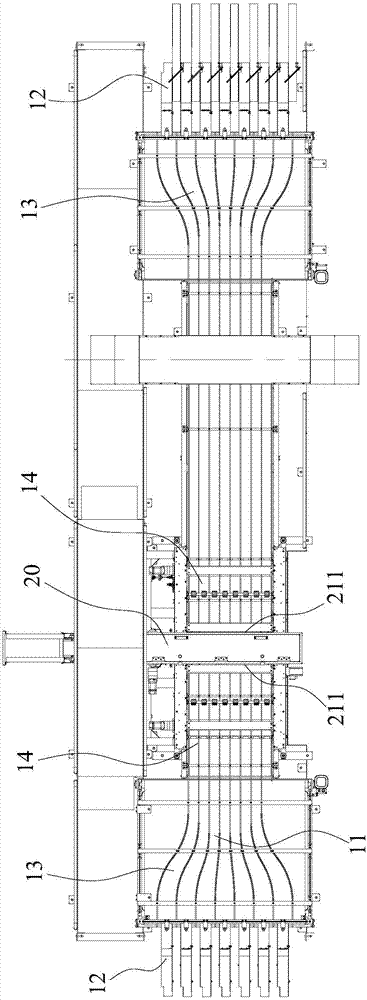

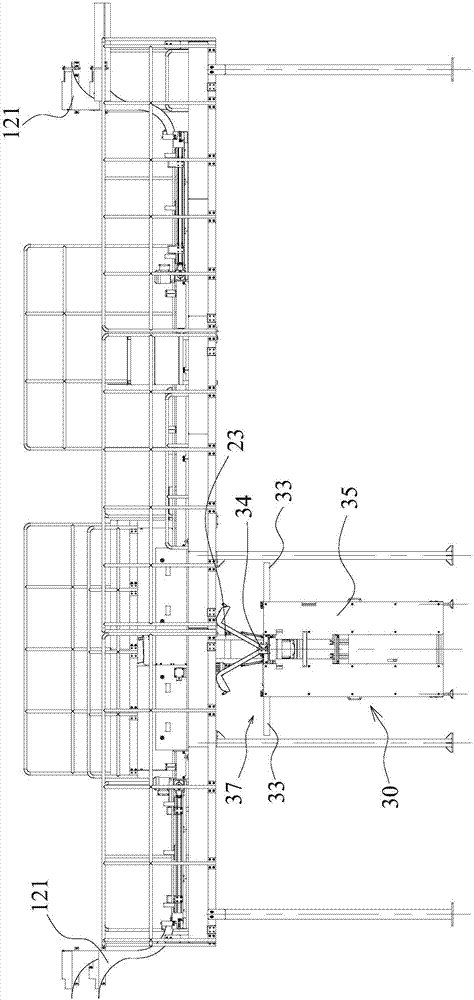

[0038] Such as Figure 1-4 As shown, in order to improve the delivery efficiency of boxed products and avoid the shutdown of the entire production line caused by external equipment failures, the present invention provides a high-position two-way storage integrated system, which includes sequentially connected self-selection The channel system, the two-way collector 20 and the stocker 30, wherein the optional channel system and the two-way collector 20 are all set at a high position, and the bar stocker 30 is set at a low position. In this example, the height of the high position is higher than or equal to 2 meters, and the self-selecting channel system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com