Intelligent truck loading system and method for cement bags

A cement bag and intelligent technology, applied in the field of cement bag intelligent loading system, can solve the problems of high labor intensity, low efficiency and high loading cost of workers, and achieve the effects of improving loading efficiency, reducing splashes and ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate understanding of the present application, the present application enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present application, and should not be regarded as a specific limitation on the present application.

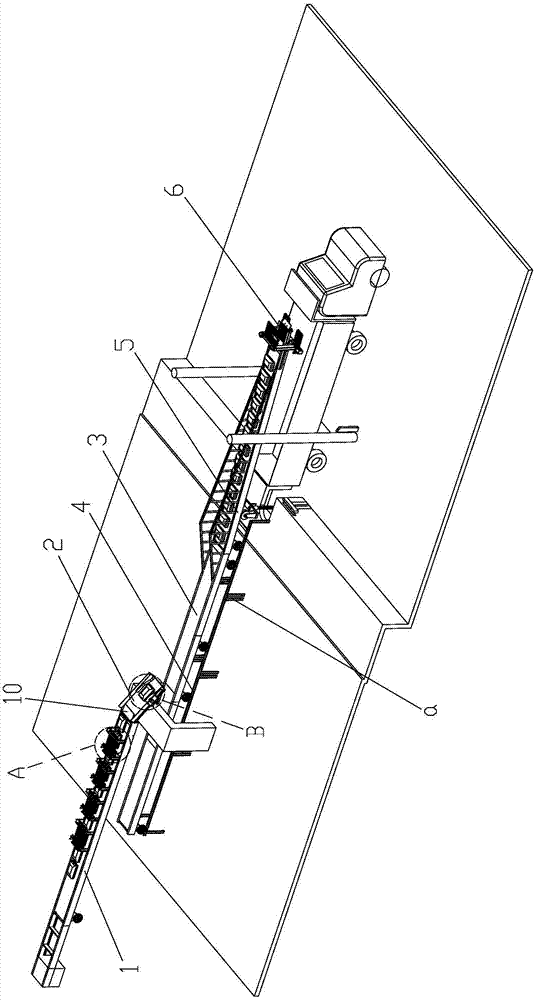

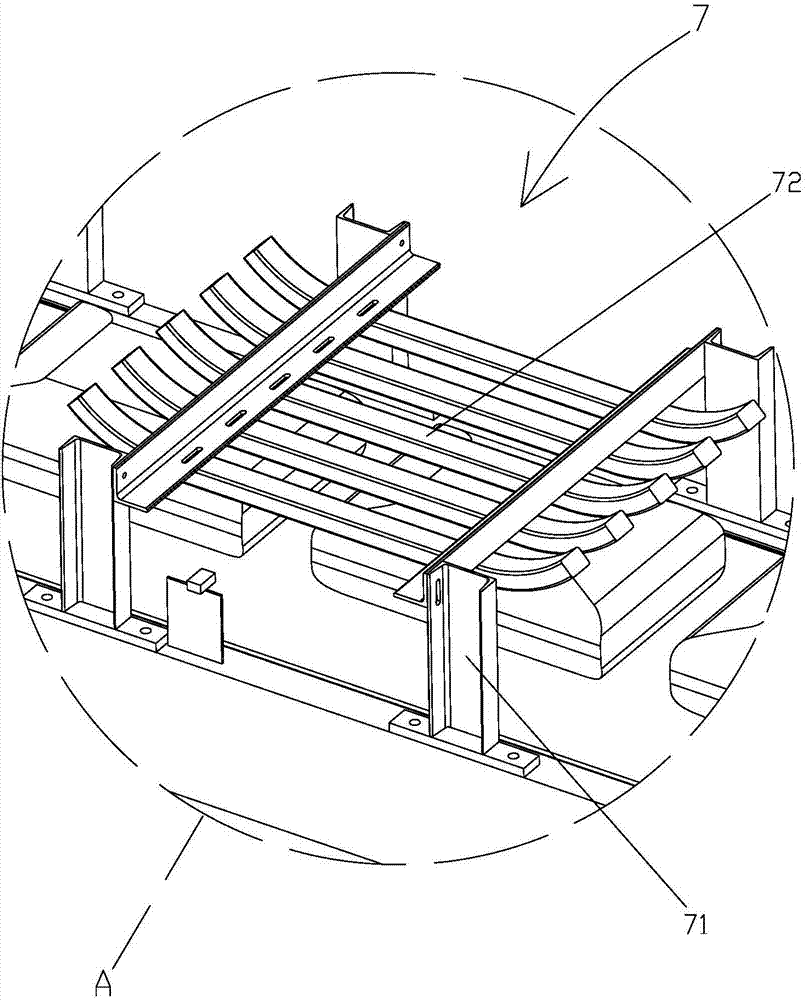

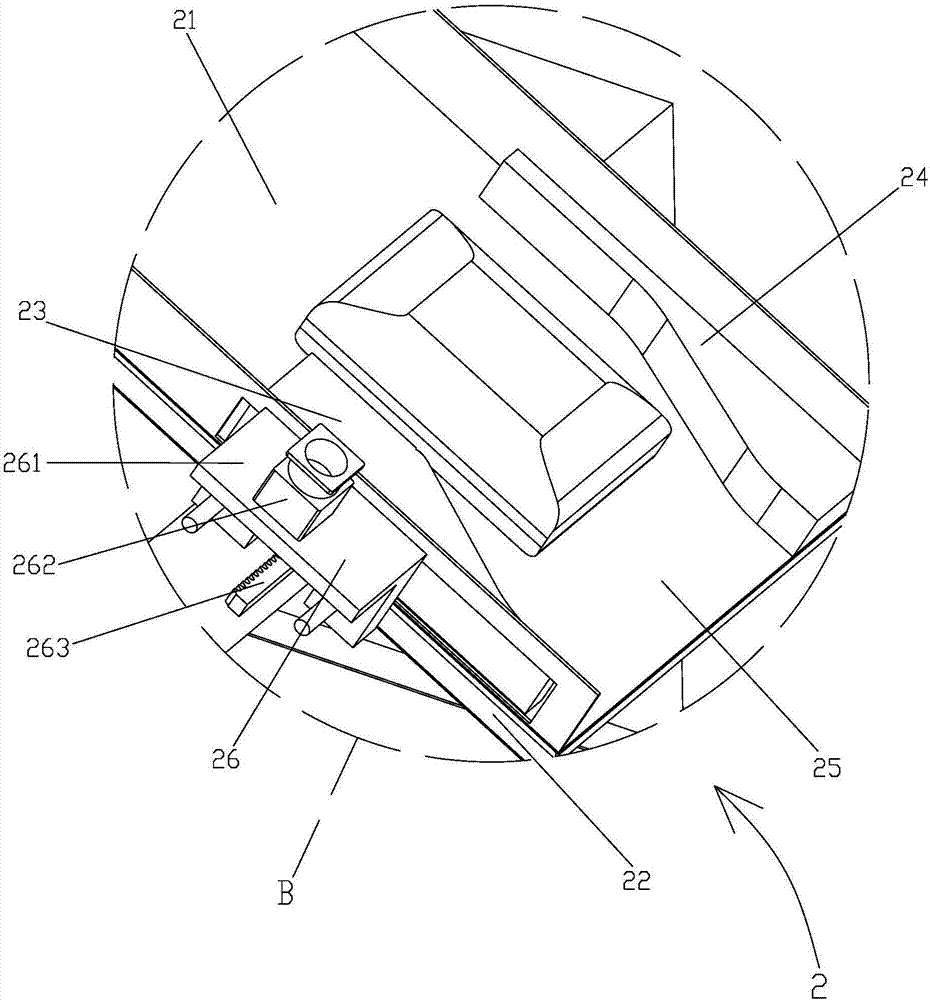

[0041] Please see Figure 1 to Figure 9 , cement bag intelligent loading system, including discharge conveyor belt 1, cement bag direction adjustment device 2, discharge deceleration conveyor belt 3, discharge loading conveyor belt 5, discharge loading conveyor belt sliding track 4, material distribution code Stacking device 6 and lifting and traversing driving device. Wherein, the discharge conveyor belt 1 is fixed on the elevated shelf of the factory building, and is used to transport the cement bags to be loaded; the input end of the cement bag direction adjustment device 2 is arranged at the output port of the discharge conveyor belt 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com