A low-concentration and high-efficiency composite oil displacement composition

A composite oil displacement and composition technology, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of complex composition of surfactants, increase the economic cost of oil displacement solution, and high dosage, etc. Simple, enhanced oil recovery, high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

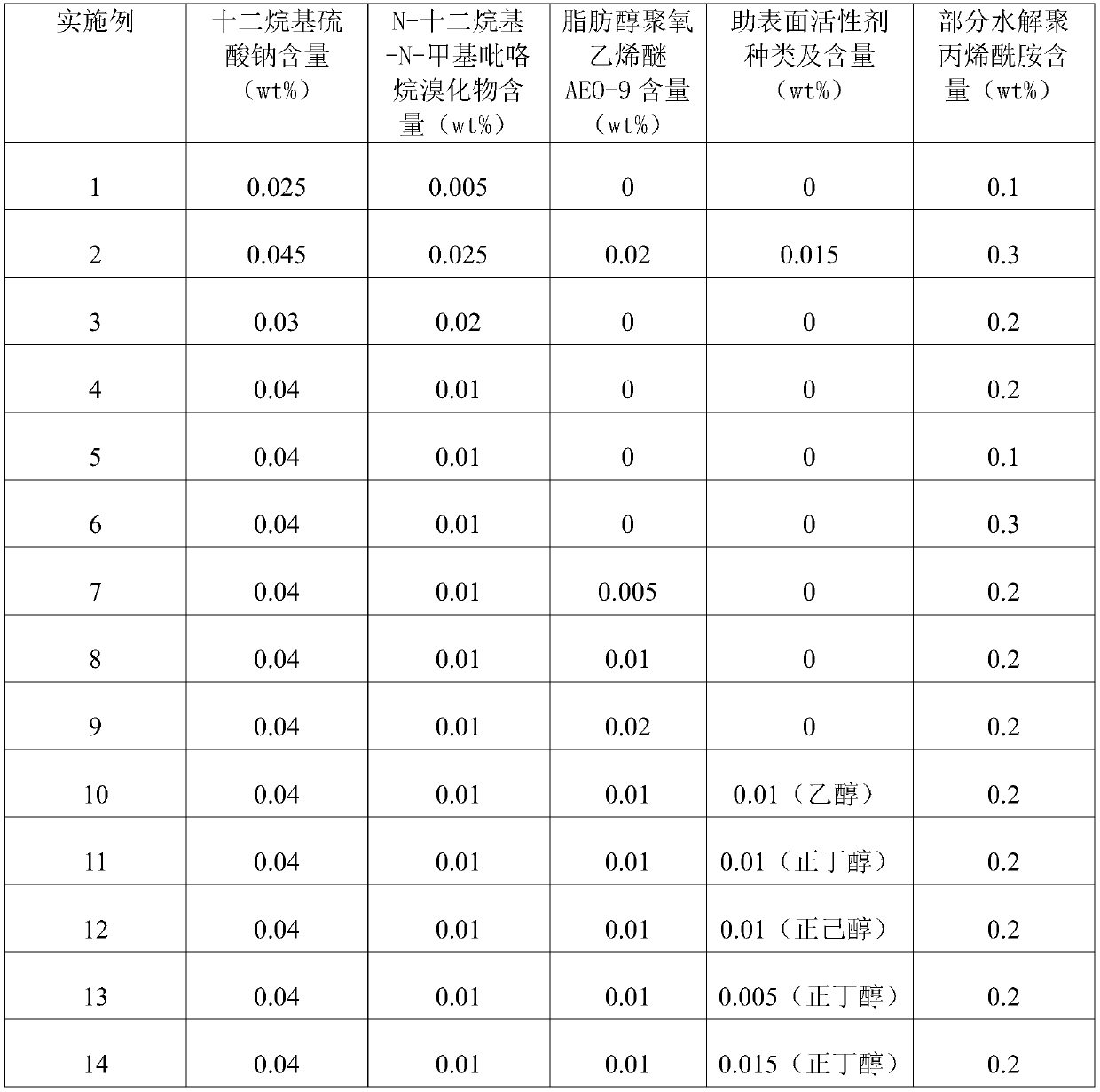

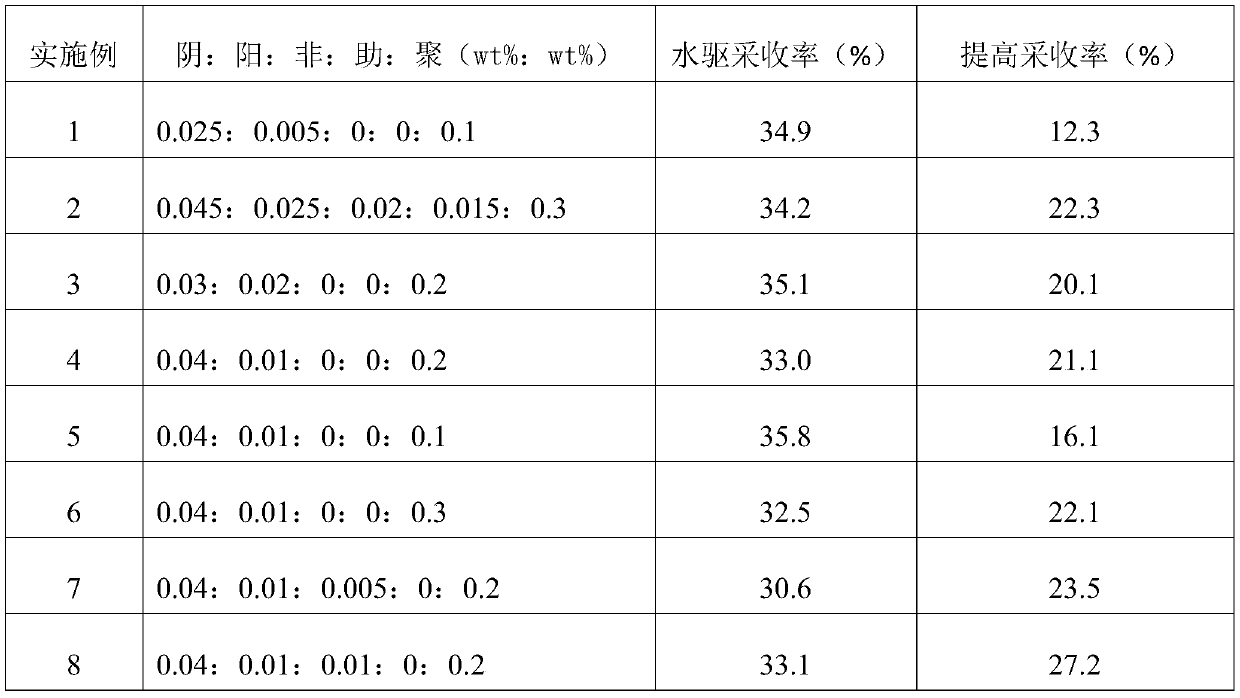

[0018] A low-concentration and high-efficiency composite oil displacement composition of the present invention will be described in detail below in conjunction with the examples.

[0019] 1. Reagent and instrument preparation

[0020] 1. Reagent preparation

[0021] Anionic surfactant sodium lauryl sulfate; 1-bromododecane, methylpyrrolidine, toluene, tetrahydrofuran; nonionic surfactant fatty alcohol polyoxyethylene ether AEO-9; ethanol, n-butanol, n-hexyl Alcohols; all of the above were of analytical grade and purchased from Aladdin Reagent Company. Partially hydrolyzed polyacrylamide (molecular weight 2 × 10 7 , degree of hydrolysis 23%) was purchased from Beijing Hengju Chemical Group Co., Ltd.

[0022] Anionic surfactant petroleum sulfonate KPS was provided by PetroChina Xinjiang Oilfield Company; zwitterionic surfactant alkyl betaine JS-33 was provided by PetroChina Jidong Oilfield Company; nonionic surfactant alkyl glycoside APG Provided by Shanghai Fakai Chemical C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com