Device for measuring friction torque of curved groove ball bearing

A technology of curved groove ball bearings and friction torque, applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems affecting measurement accuracy and achieve the effects of improving measurement accuracy, convenient adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation

[0015] Specific embodiments are given below in conjunction with the accompanying drawings.

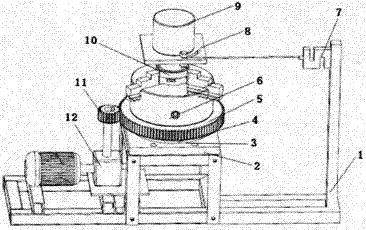

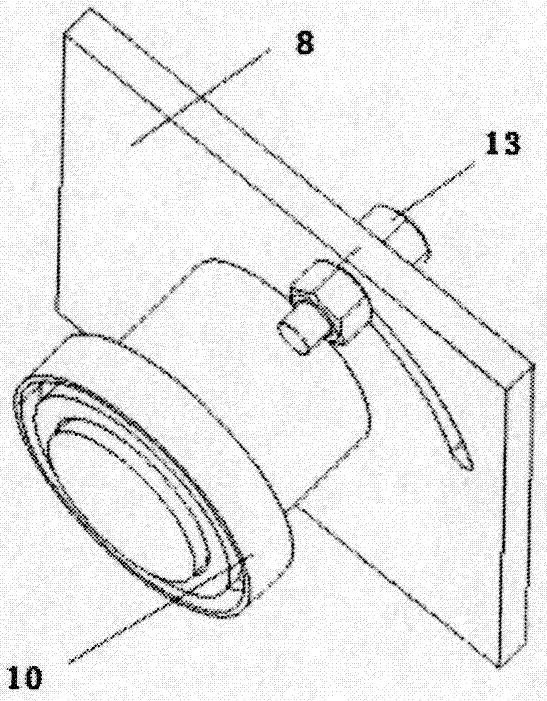

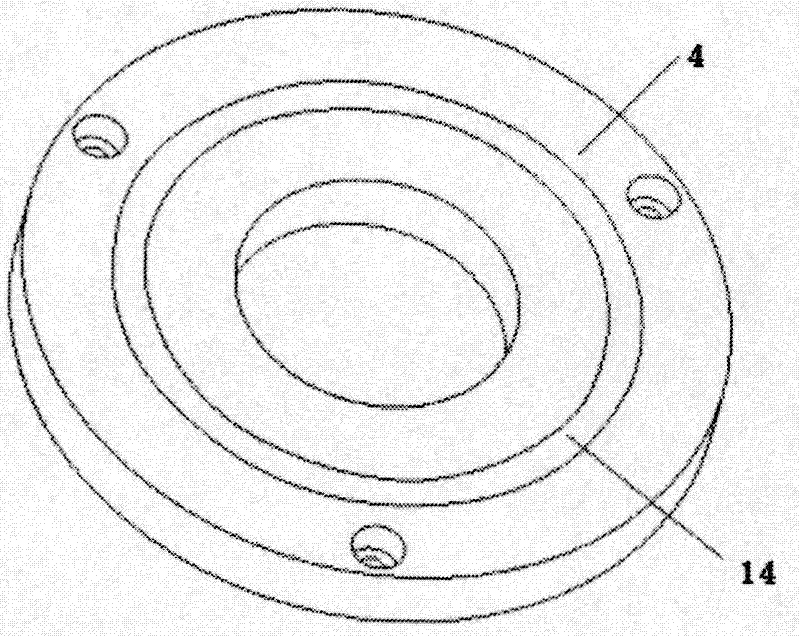

[0016] A specific embodiment of the present invention is to make a curved groove ball bearing friction torque measuring device with a total length of 850mm, and use it to measure the friction torque of the curved groove ball bearing, specifically as follows figure 1 , figure 2 , image 3 and Figure 4 shown. After the motor reducer 12 outputs power, it is further decelerated by the pinion 12 to reach the lower speed required for friction torque measurement; the base 2 is fixed on the frame 1, and the number of steel balls on a circumference of the base 2 is equal to that of the tested bearing 10 The spherical socket 15, the rotating part 4 and the three-jaw chuck are fixed together, and an "S"-shaped circle with the same amplitude and pitch as the outer ring of the bearing 10 under test is machined on the circumference corresponding to the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com