Transformer framework internally provided with multilayer circuit and preparing method thereof

A transformer skeleton and multi-layer circuit technology, applied in the field of transformers, can solve problems such as low height and small volume, and achieve the effects of cost reduction, good economic benefits, and good comprehensive performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

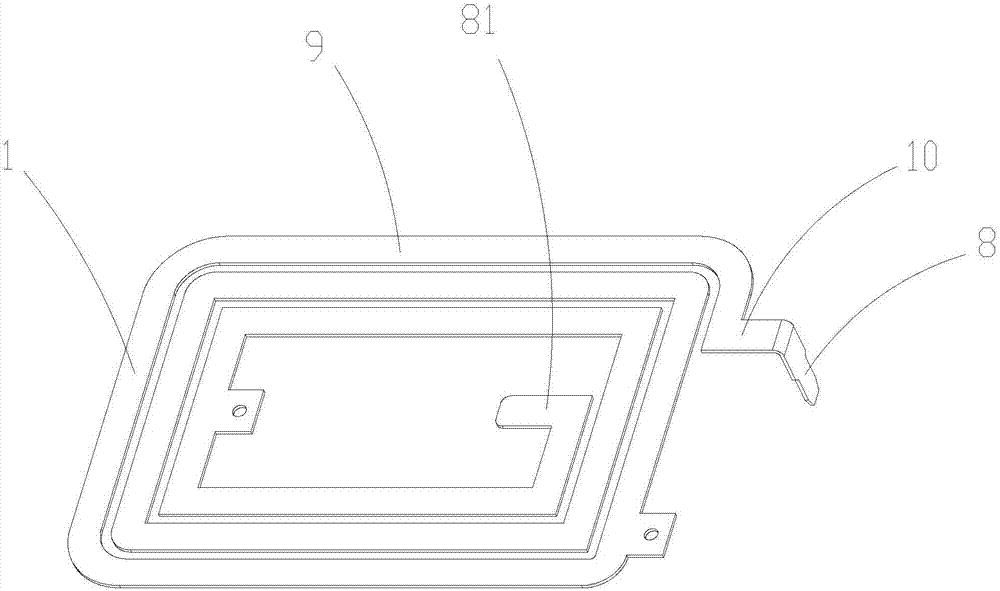

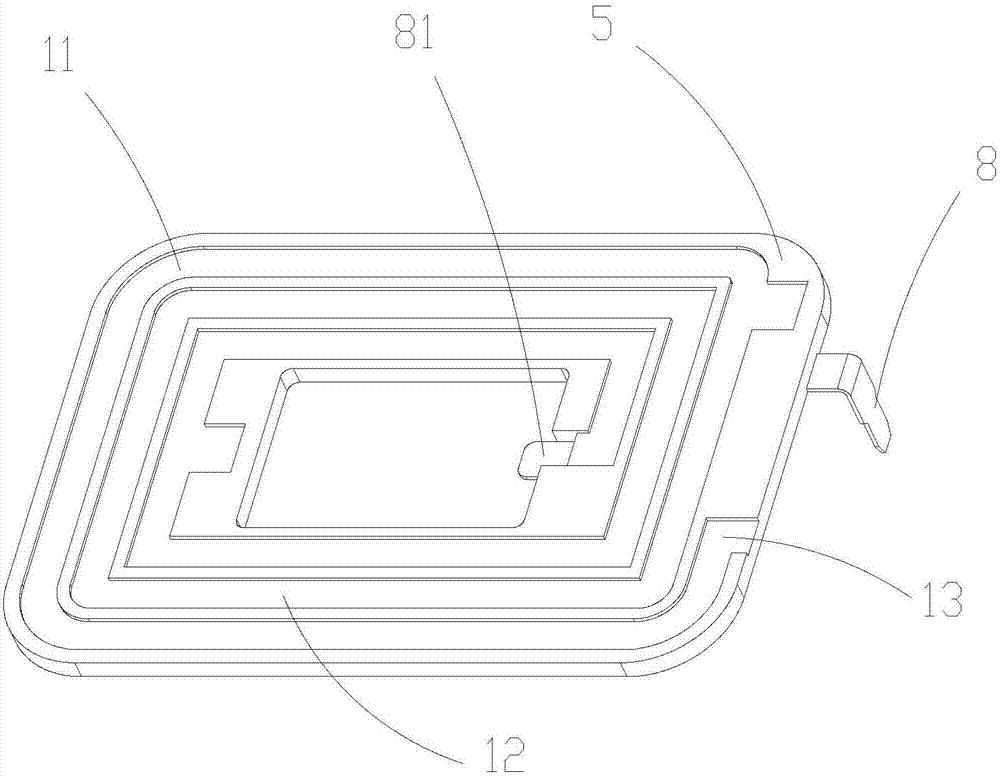

[0041] See Figure 1 to 11 In this embodiment, a transformer skeleton with built-in multilayer circuits includes a skeleton body molded from insulating plastic injection molding. The skeleton body is provided with n layers of metal sheets and plastic layers that play a role of conducting electricity. n is a natural number greater than 1, n Layers of metal sheets are stacked in the frame body at intervals. In this embodiment, 4 layers of metal sheets are preferred, including a first metal sheet 1, a second metal sheet 2 located on the inner side, and a third metal sheet 3 and a fourth metal sheet 4 located on the outer side, in the order from top to bottom. The three metal sheets 3, the second metal sheet 2, the first metal sheet 1 and the fourth metal sheet 4, and the first metal sheet 1 and the second metal sheet 2 are electrically connected, and the third metal sheet 3 and the fourth metal sheet 4 are electrically connected. connection.

[0042] The metal sheet includes an ann...

Embodiment 2

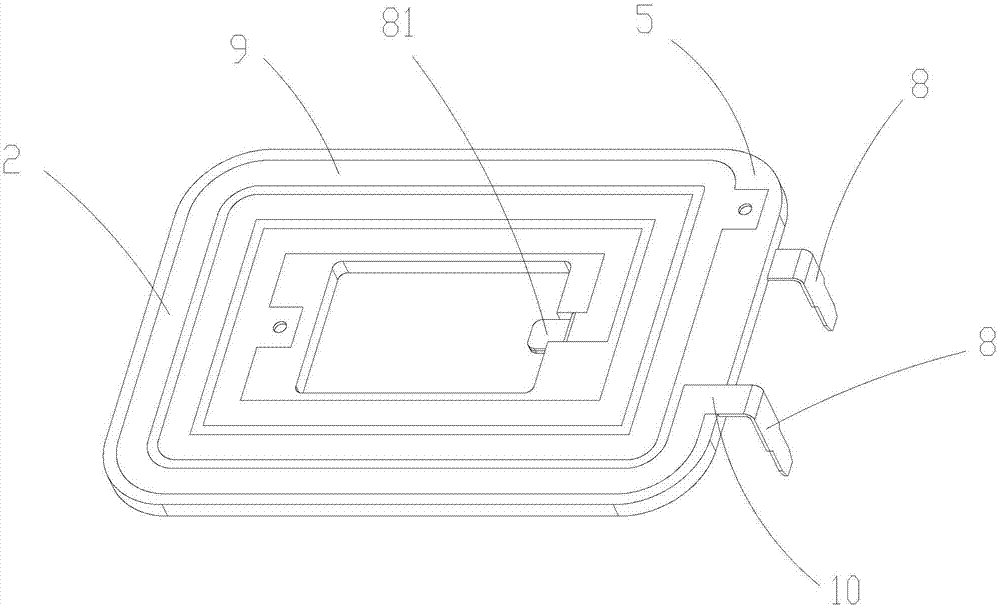

[0059] See Figure 12 to 13 The transformer skeleton with built-in multilayer circuit in this embodiment is basically the same as the first embodiment. The difference lies in: the first metal sheet 1 and the second metal sheet 2 in the transformer skeleton with built-in multilayer circuit in this embodiment The connecting portion 81 extends to the outside of the first injection layer 5 and then bends downward to form a pin 8, and the extension direction of the pin 8 is the same as the extension direction of the remaining pins 8 of the first metal sheet 1 and the second metal sheet 2 the same.

[0060] The transformer skeleton with built-in multilayer circuit of the present invention uses metal sheets to replace the existing flat winding or the PCB form with copper foil attached to the surface, which not only has good overall performance and effect, but also reduces the cost of the existing transformer; The metal sheet has a large cross-sectional area, which can be applied to hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com