Aerobic mushroom fruiting workshop

A technology for fruiting workshop and mushrooms, applied in the field of shiitake mushroom cultivation equipment, can solve the problems of shading, uneven humidity and temperature, inability to apply factory management, and uneven growth of shiitake mushrooms, etc., so as to achieve convenient cultivation and save time for cultivation. , the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

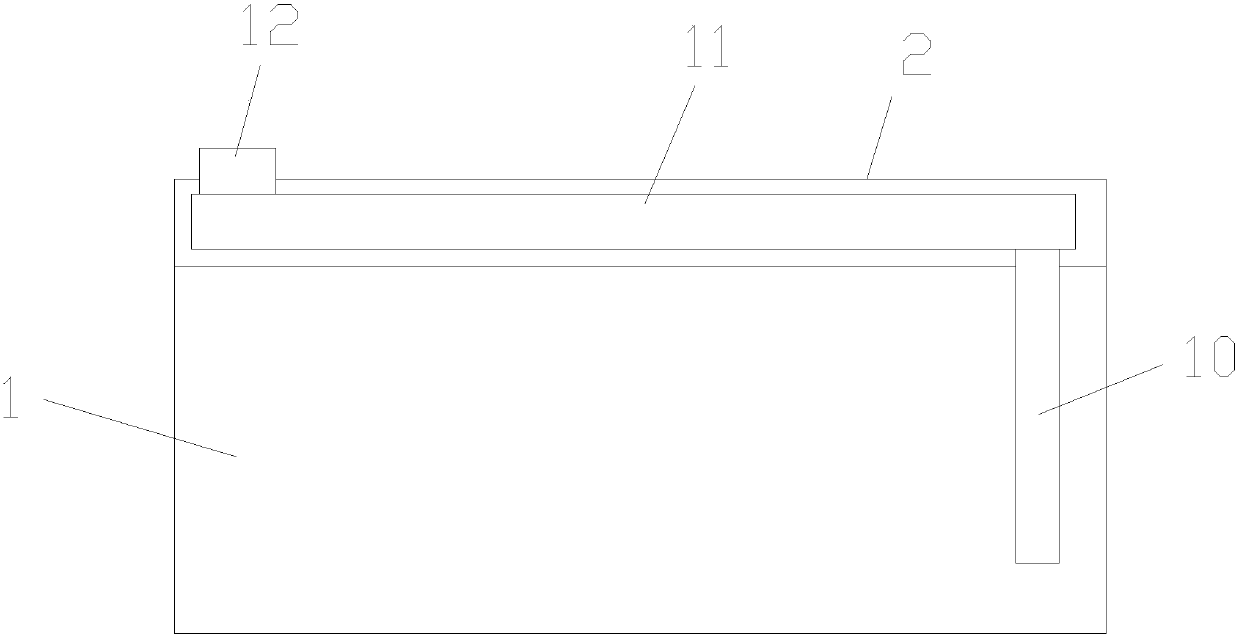

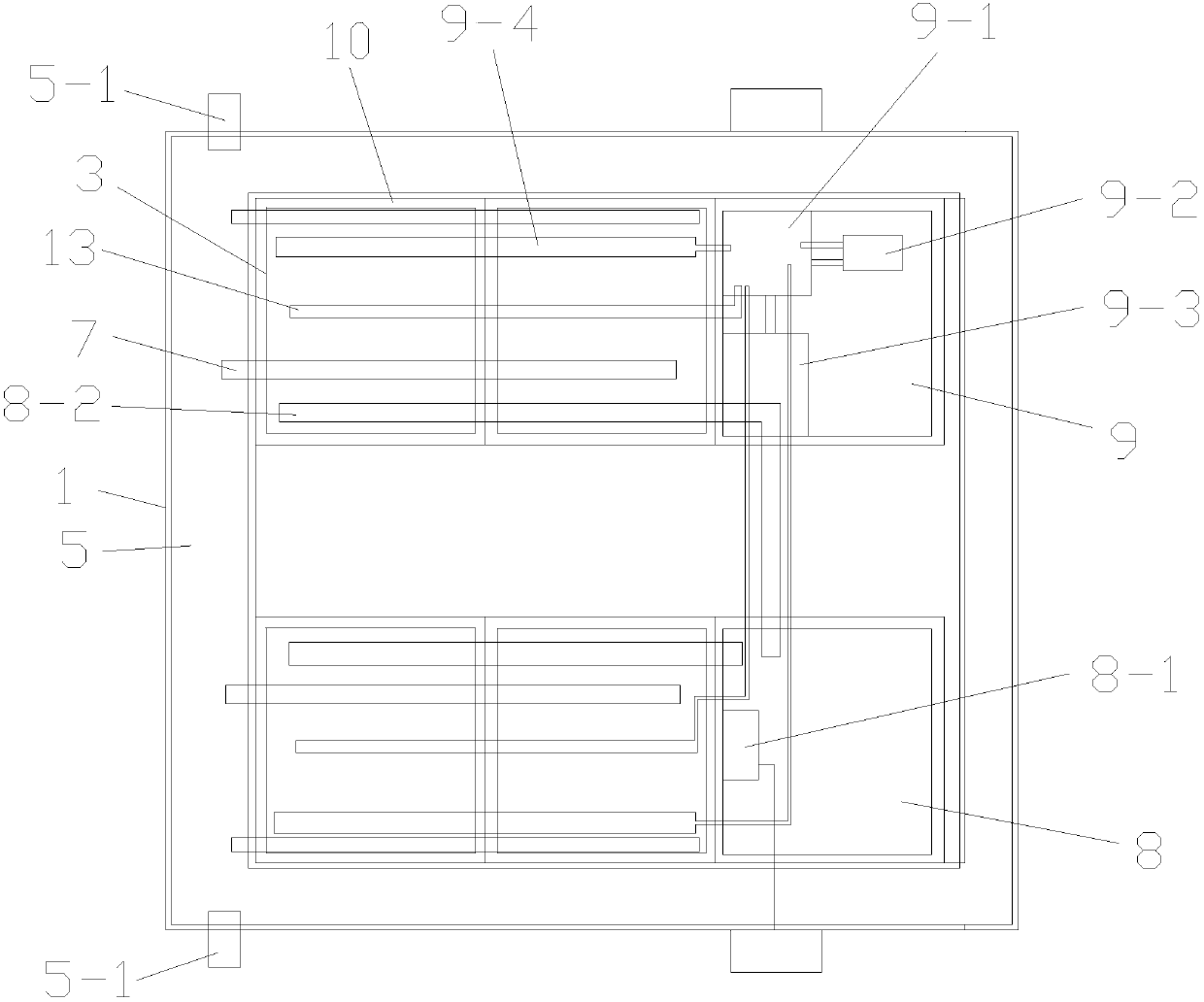

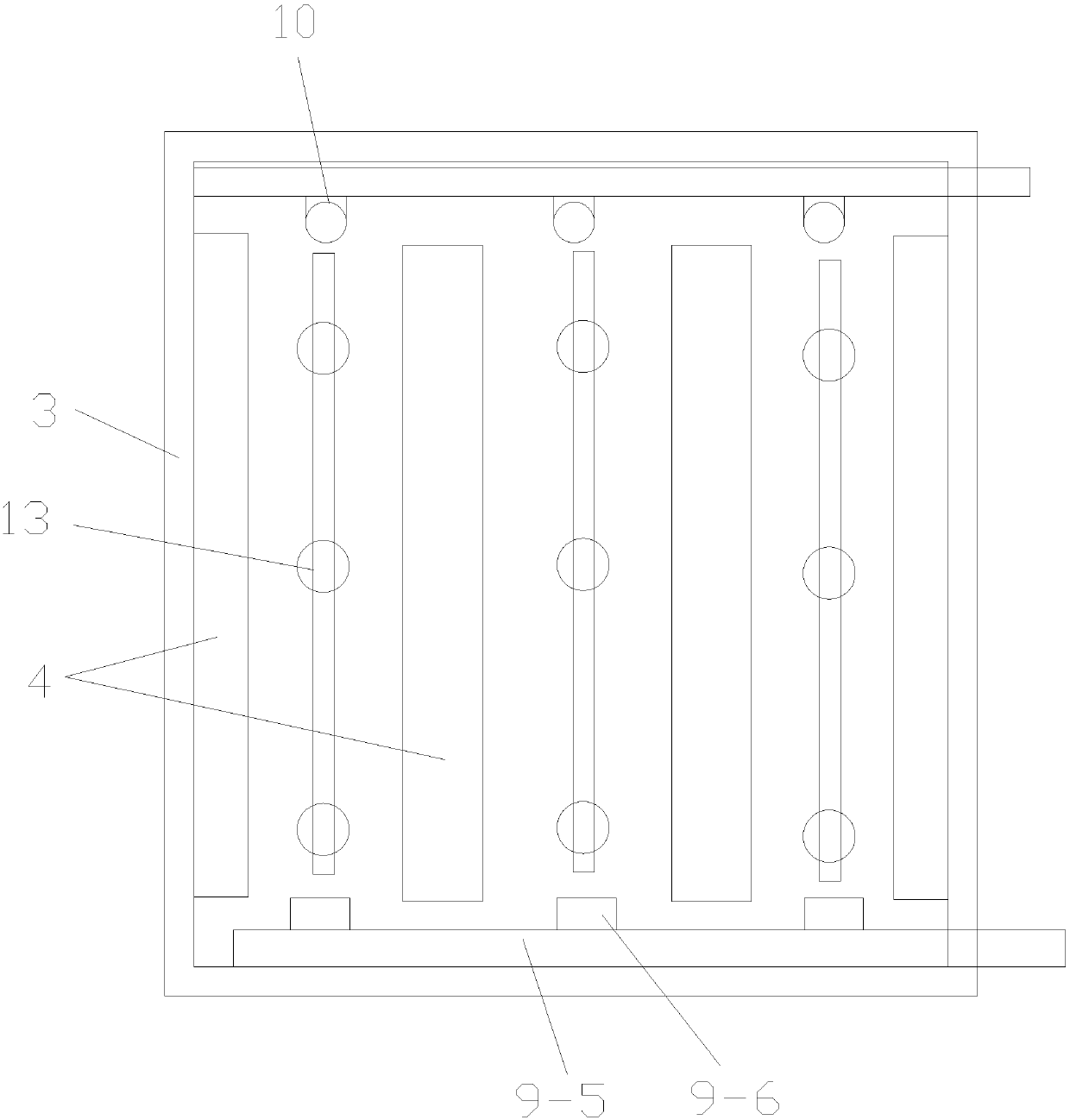

[0029] Referring to the accompanying drawings: the aerobic mushroom fruiting workshop in this embodiment includes an outer wall 1, a ceiling 2, and a mushroom house 3. There are racks 4 for placing shiitake mushrooms at intervals in the mushroom house 3, and the inner side of the outer wall 1 is provided with There is an air storage cavity 5, the air storage cavity 5 is connected with an air inlet 5-1, an oxygen pipeline 7 is installed in the air storage cavity 5, and the oxygen pipeline 7 is connected to the mushroom house 3;

[0030] Wherein the mushroom house 3 is provided with an air-conditioning storage chamber 8 and a cold water storage chamber 9, an air cooler 8-1 is installed in the air-conditioning storage chamber 8, an air-conditioning pipeline 8-2 is installed in the air-conditioning storage chamber 8, and the air-conditioning pipeline 8-2 is connected Mushroom h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com