Coolant oil filtering device for small substation transformer

A technology of filtering device and substation, which is applied in filtering separation, filtering circuit, chemical instruments and methods, etc., can solve the problems of affecting filtering effect, low filtering efficiency, and water vapor cannot be filtered and separated, and achieve the effect of improving filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

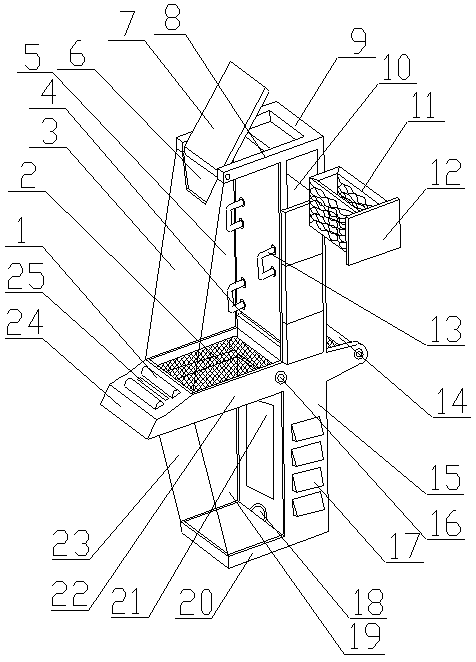

[0024] A small substation transformer cooling oil filter device of the present invention is realized in this way. When in use, first connect the power roller (14) with the external motor, connect the coils on the two drive rollers (1), and then open the cover plate (7), put the cooling oil into the uppermost filter frame (11), the sludge and insoluble colloids are filtered through the filter basket and remain in the filter frame (11), and the cooling oil enters the lower layer through the connecting pipe (13) In the filter frame (11), the cooling oil is filtered layer by layer, and the sludge and insoluble colloid in the cooling oil are filtered out. The filtered cooling oil enters the water molecule separation chamber (5) through the oil outlet tank, and the metal The filter is energized, and then the water molecules in the cooling oil are electrolyzed, and most of the gas generated by electrolysis flows out through the air outlet groove (6), and the electrolyzed cooling oil g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com