A loading and unloading device capable of changing the direction of the cutter head

A loading and unloading device and cutter head technology, which is applied to storage devices, loading/unloading, and unstacking of objects, etc., can solve the problems of affecting loading and unloading efficiency, single use performance, and long transmission time, so as to improve the efficiency and cost of loading and unloading of objects. Low, the effect of improving the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

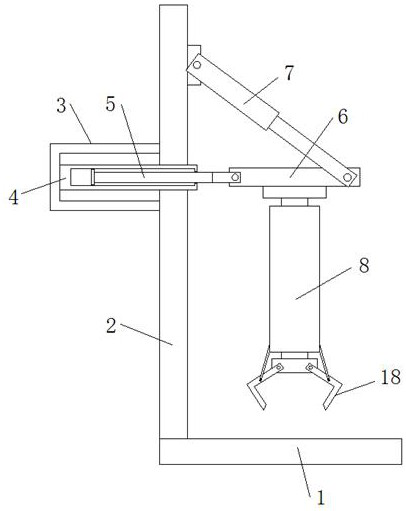

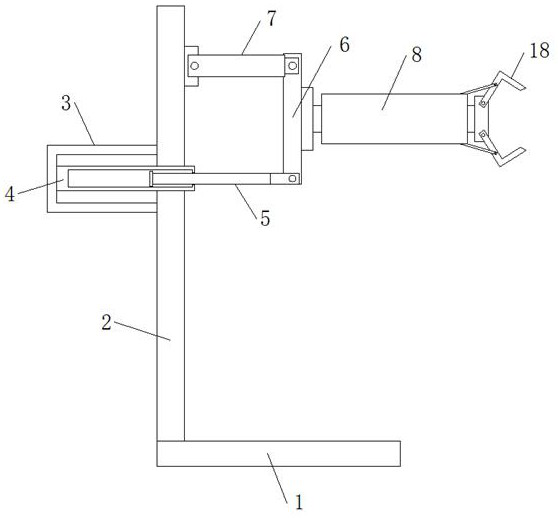

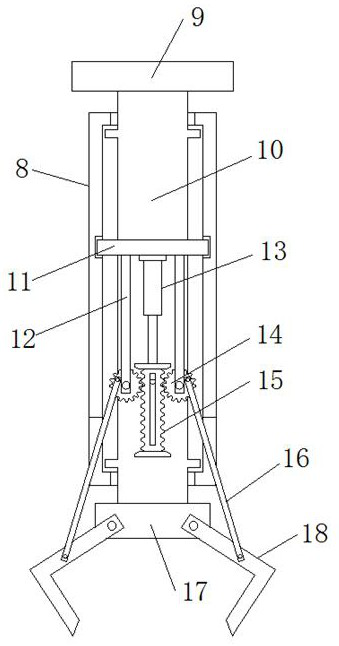

[0026] refer to Figure 1-4 , a loading and unloading device that can change the direction of the cutter head, including a fixed seat 1 and a support plate 2, the support plate 2 is vertically installed on the top side of the fixed seat 1, and also includes a steering mechanism and a loading and unloading mechanism at the bottom of the steering mechanism;

[0027] Wherein the steering mechanism installed on the support plate 2 includes a fixed bracket 3 and a hydraulic cylinder 7, the fixed bracket 3 is welded on the side of the support plate 2 away from the fixed seat 1, and the fixed bracket 3 is welded with a horizontally arranged fixed plate 4, the fixed plate One side of 4 is movably installed with a telescopic plate 5 located on the same level as the fixed plate 4, and one end of the telescopic plate 5 is rotatably connected to one end of a steering plate 6, and the steering plate 6 is located directly above the fixed seat 1, and the hydraulic cylinder 7 rotates Installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com